Custom Aerospace & Aviation Manufacturing

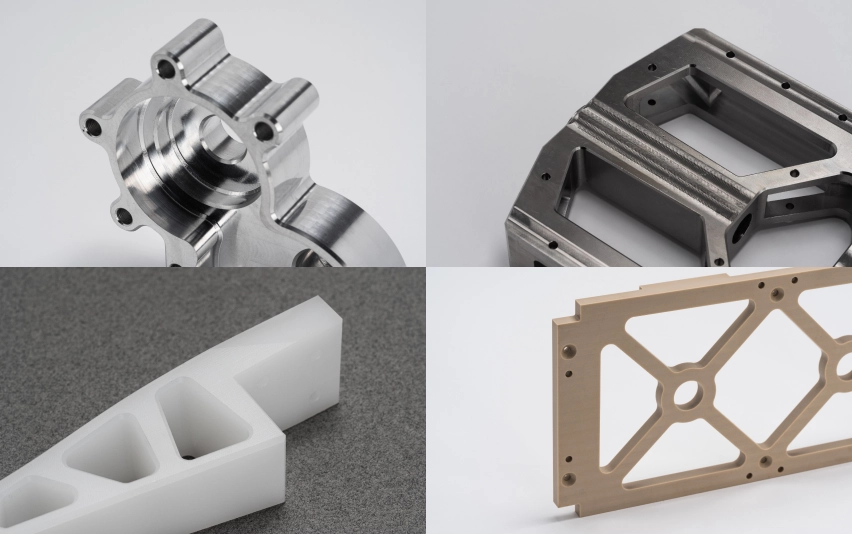

Partner with BZ Metal Products for precision-engineered components that meet the highest industry standards. From prototypes to production parts, we deliver quality and reliability for your aerospace applications.

Get Instant QuoteQuality Documentation

- CMM Inspection Reports

- Material Test Reports

- Certificates of Conformance

- First Article Inspections

Quality Standards

- Precision Measurement

- Strict Quality Control

- Advanced Testing Equipment

- 100% Part Inspection

Aerospace & Aviation Applications

We manufacture precision components for various aerospace applications, from commercial aviation to defense systems.

Commercial Aviation

High-precision components for commercial aircraft and systems.

- Engine components

- Landing gear parts

- Interior fittings

- Structural elements

Defense Aviation

Critical components for military aircraft and defense systems.

- Tactical systems

- Avionics housings

- Weapon mounts

- Structural components

UAV Systems

Lightweight components for unmanned aerial vehicles.

- Airframe structures

- Propulsion components

- Control surfaces

- Payload systems

Avionics

Precision-engineered components for aviation electronics.

- Electronic enclosures

- Sensor housings

- Control panels

- Mounting brackets

Space Systems

Specialized components for space applications.

- Satellite components

- Launch vehicle parts

- Ground support equipment

- Thermal protection

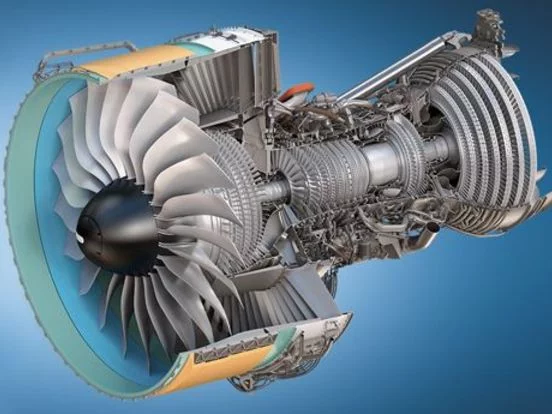

Aero Engines

Critical components for aircraft propulsion systems.

- Turbine components

- Fuel system parts

- Compressor components

- Engine mounts

Materials & Surface Finishes

We work with aerospace-grade materials and provide industry-standard surface treatments to meet your exact specifications.

Aerospace Materials

Aluminum Alloys

- 6061-T6

- 7075-T6

- 2024-T3

Stainless Steel

- 17-4 PH

- 316L

- 15-5 PH

Titanium

- Ti-6Al-4V

- Ti Grade 5

- Ti Grade 2

Special Alloys

- Inconel 718

- Invar 36

- Monel 400

Surface Finishes

Anodizing

- Type II

- Type III (Hard)

- Chromic

Plating

- Nickel

- Chrome

- Zinc

Chemical Treatments

- Passivation

- Alodine

- Phosphating

Specialty Coatings

- PTFE

- Powder Coating

- Dry Film Lube

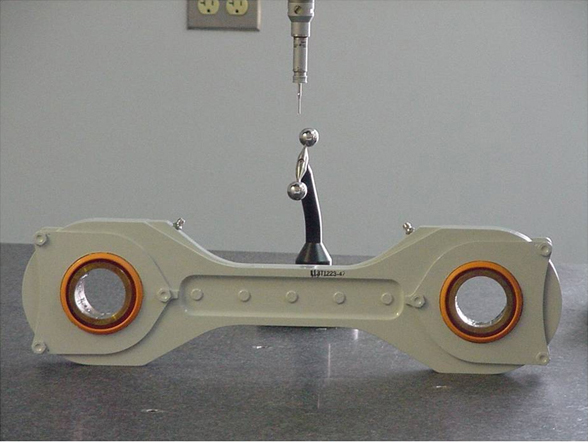

Our Quality Assurance Process

We follow a rigorous quality control process to ensure every component meets aerospace industry standards and your exact specifications.

Initial Inspection

Comprehensive review of materials and specifications before manufacturing begins.

- Material certification verification

- Drawing and specification review

- Manufacturing process planning

- Quality requirements assessment

In-Process Control

Continuous monitoring and inspection throughout the manufacturing process.

- First article inspection

- Dimensional verification

- Process parameter monitoring

- Real-time quality checks

Testing & Validation

Comprehensive testing to ensure compliance with specifications.

- Non-destructive testing

- Material properties verification

- Functional testing

- Surface finish inspection

Final Inspection

Thorough examination of finished components before delivery.

- CMM measurement verification

- Visual inspection

- Documentation review

- Packaging inspection

Documentation & Certification

Complete quality documentation package preparation.

- Certificate of Conformance

- Material certifications

- Inspection reports

- Test results documentation

Success Stories

Discover how we've helped leading aerospace companies overcome manufacturing challenges and achieve their goals.

Precision Landing Gear Components

Manufactured critical landing gear components for a major commercial aircraft manufacturer, meeting strict tolerances and safety requirements.

Advanced Avionics Housing

Developed and manufactured complex aluminum housings for advanced avionics systems, incorporating thermal management features.

Satellite Structure Components

Produced lightweight yet robust structural components for communication satellites, ensuring perfect alignment and thermal stability.

Turbine Engine Components

Manufactured high-precision turbine components with complex geometries, meeting strict material and performance requirements.

Ready to Start Your Sheet Metal Project?

Contact us now for a free quote and professional advice