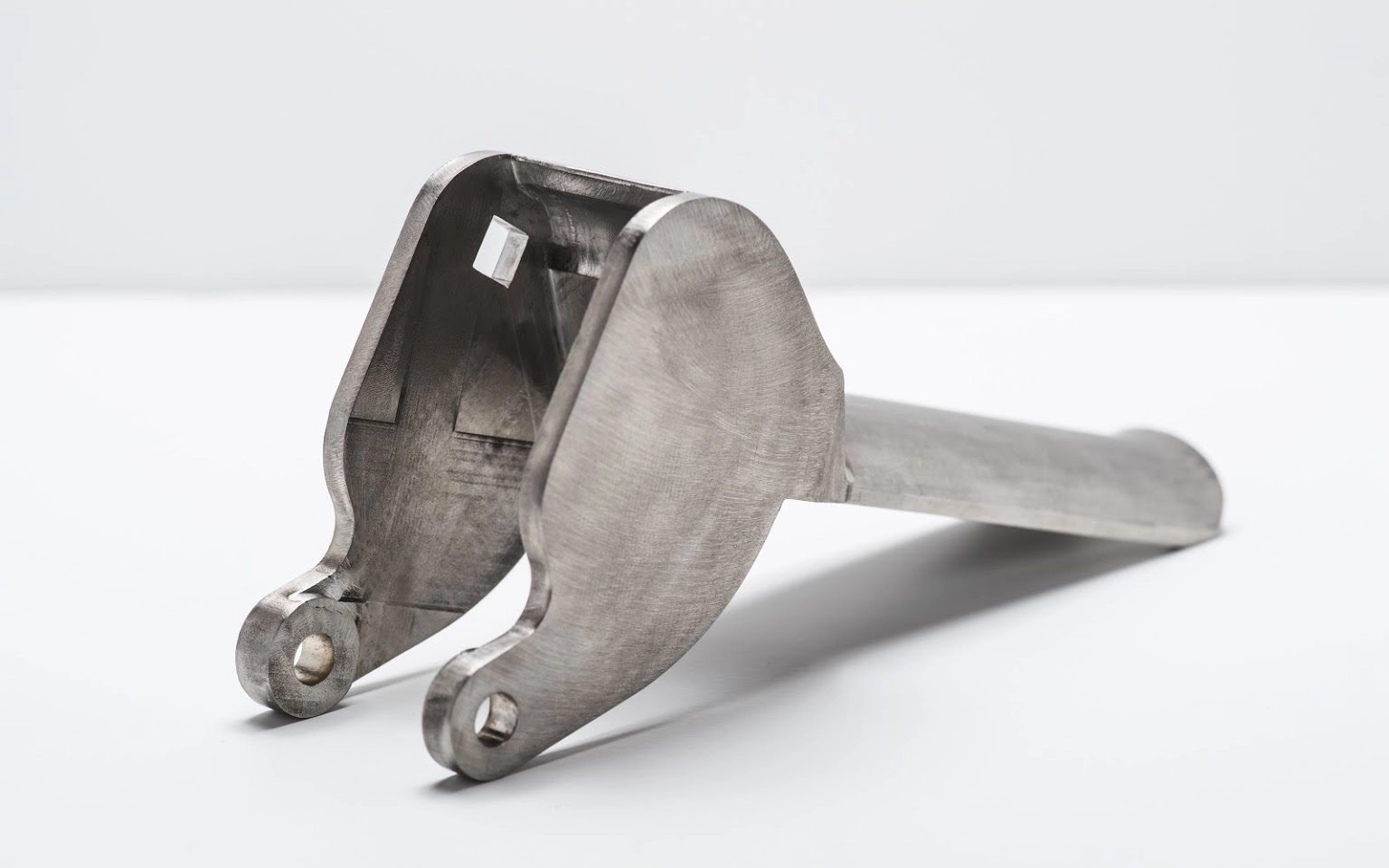

CNC Machining in Alloy Steel

High strength and toughness, fatigue resistant. Alloy steels contain other alloying elements in addition to carbon, resulting in improved hardness, toughness, fatigue and wear resistance. Perfect for applications requiring superior mechanical properties.

Order CNC Machined Alloy Steel Parts

Custom Alloy Steel Parts

Alloy steel is a versatile engineering material offering enhanced mechanical properties through the careful addition of alloying elements like chromium, nickel, molybdenum, and vanadium. These elements transform standard carbon steel into a high-performance material ideal for demanding applications where strength, hardness, and wear resistance are critical.

BZ Metal Products' CNC machining services deliver precision alloy steel components with tight tolerances and excellent surface finishes. Our capabilities include both 3-axis and 5-axis CNC milling and turning, allowing us to create complex geometries for your most demanding applications in automotive, industrial, aerospace, and energy sectors.

Superior Strength

Higher tensile and yield strength than carbon steel, making alloy steel ideal for load-bearing components and structural applications

Enhanced Durability

Excellent fatigue resistance and toughness, ensuring components can withstand cyclic loading and impact without failure

Heat Treatment Versatility

Can be heat treated to achieve specific mechanical properties, allowing customization of hardness, toughness, and wear resistance

CNC Machining Alloy Steel Materials

BZ Metal Products offers high-quality alloy steel grades for CNC machining. Our alloy steel materials provide superior strength, toughness, and wear resistance for your demanding applications.

Alloy Steel 4140

1.7225 | 42CrMo4 | EN19

Alloy steel 4140 is a chromium-molybdenum alloy steel with good strength, toughness, and wear resistance. It offers excellent fatigue strength and can be heat treated to achieve a wide range of mechanical properties.

Alloy Steel 4340

1.6511 | 36CrNiMo4 | EN24

Alloy steel 4340 is a nickel-chromium-molybdenum alloy steel that offers high toughness and strength in larger sections. It has good fatigue resistance and maintains its properties at elevated temperatures.

Additional Alloy Steel Grades Available by Request

Alloy Steel 1.7131

16MnCr5 - Case hardening steel with good core strength

Alloy Steel 1215

EN1A | 1.0715 - Free cutting steel with excellent machinability

Alloy Steel 8620

21NiCrMo2 | 1.6523 - Carburizing alloy steel with good core properties

Alloy Steel Properties Overview

| Property | Alloy Steel 4140 | Alloy Steel 4340 | Units |

|---|---|---|---|

| Tensile Strength | 655-1400 | 745-1650 | MPa |

| Yield Strength | 415-1200 | 470-1500 | MPa |

| Elongation | 10-22 | 12-22 | % |

| Hardness (Brinell) | 197-400 | 217-495 | HB |

| Modulus of Elasticity | 190-210 | 190-210 | GPa |

| Impact Strength (Charpy V-notch) | 15-54 | 20-67 | J |

| Property | Alloy Steel 4140 | Alloy Steel 4340 | Units |

|---|---|---|---|

| Density | 7.85 | 7.85 | g/cm³ |

| Melting Point | 1416-1432 | 1427-1450 | °C |

| Thermal Conductivity | 42.7 | 44.5 | W/m·K |

| Electrical Resistivity | 22.1 | 25.0 | μΩ·cm |

| Coefficient of Thermal Expansion | 12.3 | 12.3 | μm/m·K |

| Specific Heat Capacity | 473 | 475 | J/kg·K |

| Element | Alloy Steel 4140 | Alloy Steel 4340 |

|---|---|---|

| Carbon (C) | 0.38-0.43% | 0.38-0.43% |

| Manganese (Mn) | 0.75-1.00% | 0.60-0.80% |

| Silicon (Si) | 0.15-0.35% | 0.15-0.35% |

| Chromium (Cr) | 0.80-1.10% | 0.70-0.90% |

| Molybdenum (Mo) | 0.15-0.25% | 0.20-0.30% |

| Nickel (Ni) | - | 1.65-2.00% |

| Phosphorus (P) max | 0.035% | 0.035% |

| Sulfur (S) max | 0.040% | 0.040% |

Characteristics & Applications

Strength & Toughness

Alloy steels offer an excellent balance of strength and toughness due to their carefully controlled alloying elements. This makes them suitable for critical components in machinery, automotive applications, and structural parts where failure is not an option.

Heat Treatment Response

These steels respond well to various heat treatments including quenching and tempering, carburizing, and nitriding. This allows for customization of mechanical properties to meet specific application requirements, from surface hardness to core toughness.

Machinability Considerations

While alloy steels are generally harder to machine than mild steel, our specialized CNC processes and tooling optimize cutting parameters for efficient material removal while maintaining excellent surface finishes. Pre-heat treated conditions typically offer the best machinability.

Fatigue & Wear Resistance

The combination of high strength and good toughness makes alloy steels excellent for applications subject to cyclic loading and wear. Properly heat-treated alloy steel components can withstand millions of stress cycles without failure, making them ideal for gears, shafts, and other dynamic components.

Frequently Asked Questions

Get answers to common questions about alloy steel CNC machining. If you can't find what you're looking for, please contact our engineering team for assistance.

What are the key benefits of using alloy steel for my components?

Alloy steel offers several significant advantages over standard carbon steel:

- Superior Strength: Higher tensile and yield strengths, allowing for higher load-bearing capacity in smaller cross-sections

- Enhanced Toughness: Better resistance to impact and shock loading, reducing the risk of brittle fracture

- Improved Fatigue Resistance: Better performance under cyclic loading conditions, extending component life

- Greater Wear Resistance: Harder surface properties that resist abrasion and erosion

- Heat Treatment Versatility: Ability to be heat-treated to achieve specific mechanical properties

- Better High-Temperature Performance: Maintains strength and structural integrity at elevated temperatures

These properties make alloy steel ideal for components in demanding environments where standard steels would fail, such as in automotive drivetrain parts, industrial machinery, and structural applications with high stress concentrations.

What are the differences between alloy steel grades, and how do I choose?

Different alloy steel grades offer varying balances of properties based on their alloying elements:

- 4140 (Chrome-Moly): Contains chromium and molybdenum, offering good hardenability, strength, and toughness in moderate sections. Ideal for general-purpose applications requiring a good balance of properties.

- 4340 (Nickel-Chrome-Moly): Contains nickel, chromium, and molybdenum, providing excellent hardenability and toughness in large sections. Better for high-stress applications and where superior impact resistance is needed.

- 1.7131 (16MnCr5): A case-hardening steel with good core strength, designed for components requiring a hard, wear-resistant surface with a tough, ductile core.

- 8620: A nickel-chromium-molybdenum case-hardening steel with good core properties, suitable for carburized components requiring wear resistance with good core toughness.

- 1215: A free-cutting alloy steel with high machinability but lower strength, good for high-volume production where easy machining is prioritized over maximum strength.

When selecting an alloy steel grade, consider:

- Required strength and toughness levels

- Section thickness of the component

- Operating temperature range

- Need for surface hardness vs. core toughness

- Anticipated fatigue loading

- Environmental conditions (corrosion considerations)

- Heat treatment requirements and capabilities

- Machinability and production volume

Our engineering team can provide guidance on selecting the optimal alloy steel grade for your specific application requirements.

What tolerances can you achieve with alloy steel CNC machining?

With alloy steel CNC machining, we can achieve standard tolerances of ±0.125mm (±0.005″) and precision tolerances of ±0.05mm (±0.002″) for critical features. For extremely critical dimensions, we can achieve tolerances down to ±0.025mm (±0.001″) with additional post-machining processes like grinding or honing.

Several factors can affect achievable tolerances in alloy steel components:

- Heat Treatment: Post-machining heat treatment can cause dimensional changes. When tight tolerances are required, we typically rough machine, heat treat, and then finish machine to final dimensions.

- Component Size: Larger components typically have wider tolerances due to thermal effects and cumulative errors.

- Complexity: Features with complex geometries may require wider tolerances than simple features.

- Material Condition: Pre-hardened alloy steels may require wider tolerances than annealed materials.

We recommend specifying tight tolerances only for critical features while allowing standard tolerances for non-critical dimensions to optimize cost-effectiveness. Our team can advise on appropriate tolerance specifications for your specific application.

What are the different heat treatments available for alloy steel components?

We offer several heat treatment options for alloy steel components to achieve specific mechanical properties:

- Quenching and Tempering: Produces a balance of strength, hardness, and toughness throughout the entire component. Material is heated to austenitic temperature, rapidly cooled (quenched), then reheated to a lower temperature (tempered) to reduce brittleness. Ideal for components requiring good overall mechanical properties.

- Carburizing: Creates a hard, wear-resistant surface while maintaining a tough, ductile core. Carbon is diffused into the surface at high temperature, followed by quenching and tempering. Best for components subject to wear and impact, such as gears and shafts.

- Nitriding: Produces an extremely hard surface with minimal distortion. Nitrogen is diffused into the surface at moderate temperatures. Ideal for precision components requiring dimensional stability and wear resistance.

- Stress Relieving: Reduces internal stresses without significantly altering mechanical properties. Parts are heated to moderate temperatures and slowly cooled. Used to prevent distortion in complex machined parts.

- Normalizing: Refines grain structure and improves machinability by heating above the critical temperature and cooling in still air. Used as a preparatory treatment or to homogenize the structure.

- Annealing: Produces a soft, machinable condition by heating to austenitic temperature and slow cooling. Used to prepare material for machining before final heat treatment.

The optimal heat treatment depends on your component's application, loading conditions, and required properties. Our metallurgical team can recommend the appropriate heat treatment process for your specific requirements.

What design considerations are important for alloy steel CNC machining?

When designing parts for alloy steel CNC machining, consider these important factors:

- Wall Thickness: Maintain minimum wall thickness of 0.8mm to ensure structural integrity and prevent distortion during machining and heat treatment.

- Corner Radii: Use internal radii of at least 1/3 the depth of the pocket to reduce stress concentrations and tool wear.

- Heat Treatment Allowance: Include dimensional allowances (typically 0.1-0.3mm) for finishing operations after heat treatment when tight tolerances are required.

- Tool Access: Design with tool accessibility in mind, allowing sufficient clearance for cutting tools to reach all features without excessive tool projection.

- Uniform Wall Sections: Maintain relatively uniform wall thicknesses throughout the part to prevent differential cooling and distortion during heat treatment.

- Draft Angles: Include appropriate draft angles (1-3°) for deep pockets to facilitate tool access and chip evacuation.

- Thread Relief: Design with proper thread relief for internal threads to ensure full thread engagement.

- Avoid Sharp Transitions: Incorporate gradual transitions between different section thicknesses to minimize stress concentrations.

Our engineering team can provide design-for-manufacturing (DFM) reviews of your parts to ensure optimal manufacturability, performance, and cost-effectiveness.

Get Your Alloy Steel Parts Into Production

Ready to leverage the superior properties of alloy steel for your next project? BZ Metal Products offers expert CNC machining services for all alloy steel grades. From prototypes to production runs, we ensure high-quality parts that meet your exact specifications.