Aluminum 5052

EN AW-5052 | 3.3523 | AlMg2,5

Aluminum 5052 is a high magnesium alloy that offers excellent corrosion resistance, particularly in salt water environments. While not heat-treatable, it can be significantly hardened through cold working, enabling a series of "H" tempers. This versatile alloy provides an optimal balance of strength, formability, and weldability for various applications.

Material Properties

Detailed specifications and characteristics of Aluminum 5052, including mechanical properties, physical properties, and chemical composition.

| Property | Value | Units |

|---|---|---|

| Tensile Strength | 170-310 | MPa |

| Yield Strength | 65-240 | MPa |

| Elongation at Break | 12-30 | % |

| Hardness (Brinell) | 45-70 | HB |

| Shear Strength | 115-190 | MPa |

| Fatigue Strength | 110-170 | MPa |

| Modulus of Elasticity | 70.3 | GPa |

| Property | Value | Units |

|---|---|---|

| Density | 2.68 | g/cm³ |

| Melting Point | 607-649 | °C |

| Thermal Conductivity | 138 | W/m·K |

| Electrical Resistivity | 4.9 × 10^-8 | Ω·m |

| Specific Heat Capacity | 900 | J/kg·K |

| Thermal Expansion Coefficient | 23.8 × 10^-6 | K^-1 |

| Electrical Conductivity | 35 | %IACS |

Chemical Composition (% by weight)

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Aluminum (Al) | Balance | Balance |

| Magnesium (Mg) | 2.2 | 2.8 |

| Chromium (Cr) | 0.15 | 0.35 |

| Iron (Fe) | - | 0.40 |

| Silicon (Si) | - | 0.25 |

| Copper (Cu) | - | 0.10 |

| Manganese (Mn) | - | 0.10 |

| Zinc (Zn) | - | 0.10 |

| Others (each) | - | 0.05 |

| Others (total) | - | 0.15 |

Applications & Features

Explore the common applications of Aluminum 5052 and discover the key features that make it ideal for various industries.

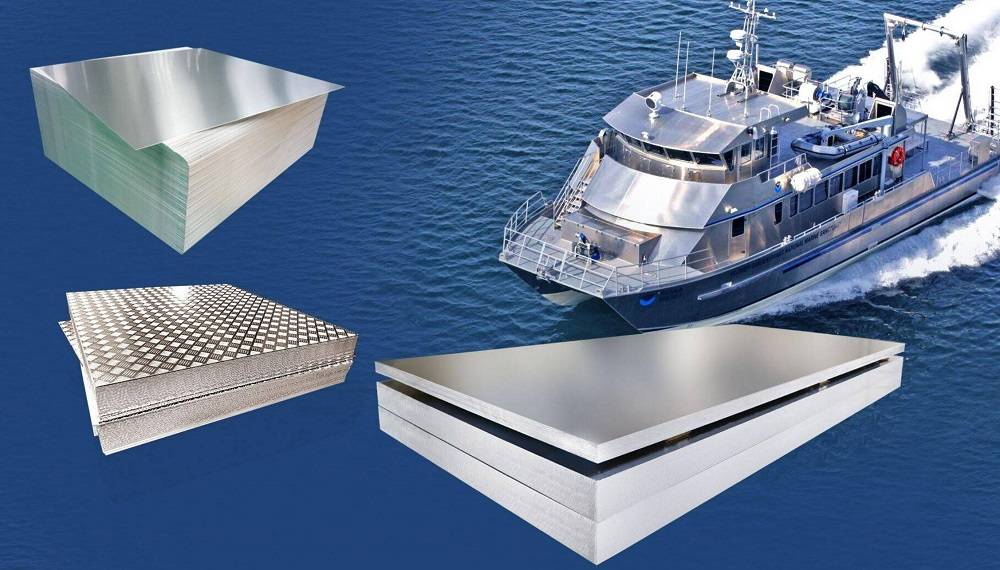

Marine Applications

Aluminum 5052's excellent corrosion resistance to salt water makes it ideal for boat hulls, marine hardware, pontoons, and other components exposed to marine environments. Its moderate strength combined with good formability allows for complex marine structures.

Electronic Enclosures

The excellent formability and good electrical conductivity of Aluminum 5052 make it perfect for electronic enclosures and housings. Its corrosion resistance ensures longevity in various environmental conditions, while its moderate strength provides adequate protection.

Food & Beverage Equipment

With its good corrosion resistance and non-toxic nature, Aluminum 5052 is extensively used in food processing equipment, commercial kitchen appliances, and containers. It meets FDA requirements for food contact and can be easily cleaned and sanitized.

Key Advantages

-

✓Superior Corrosion ResistanceExcellent resistance to atmospheric and salt water corrosion, making it ideal for marine and outdoor applications.

-

✓Good FormabilityCan be easily formed, drawn, and bent without cracking, allowing for complex shapes and designs.

-

✓Excellent WeldabilityCan be readily welded using various methods including TIG, MIG, and resistance welding techniques.

-

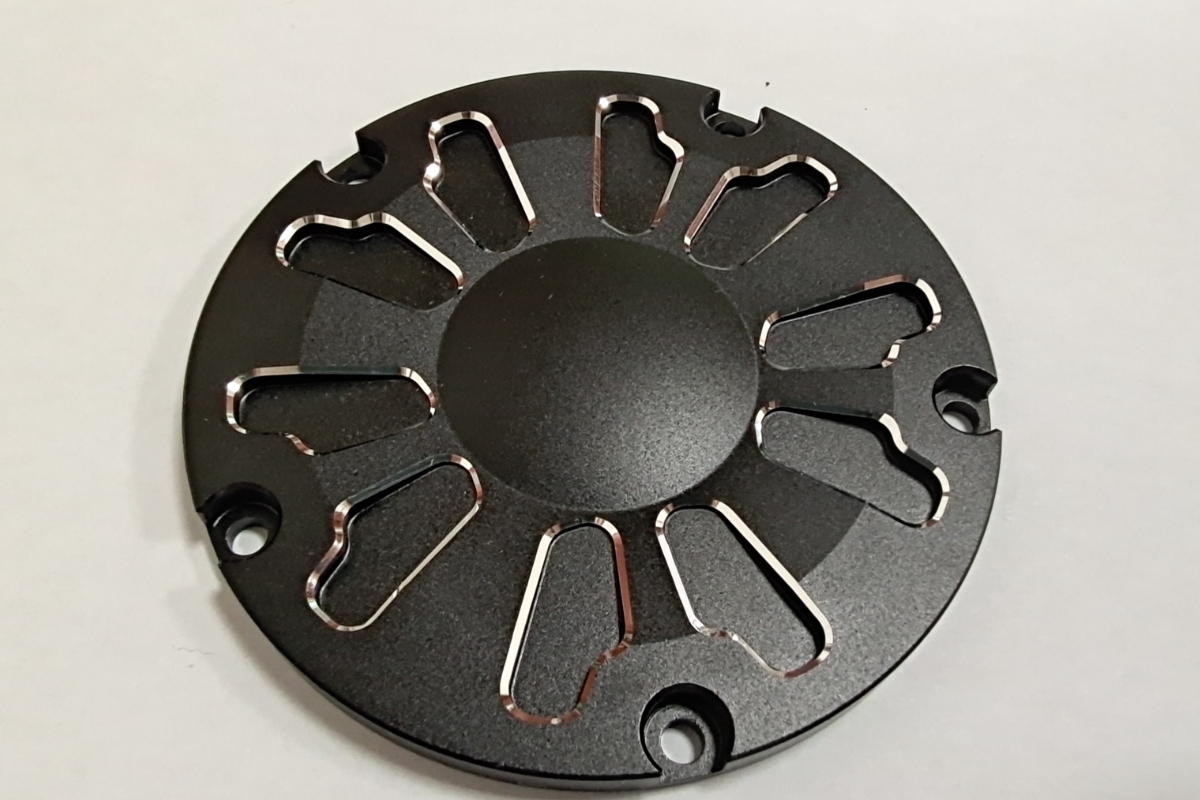

✓Good MachinabilityMachines well with standard tooling and techniques, allowing for precise and economical part production.

Additional Applications

-

✓Aircraft ComponentsUsed in non-structural aircraft parts, fuel tanks, and interior components due to its good strength-to-weight ratio.

-

✓Medical EquipmentFound in various medical devices and equipment where corrosion resistance and moderate strength are required.

-

✓Architectural ApplicationsUsed in architectural trim, panels, and decorative elements due to its good formability and finish characteristics.

-

✓TransportationApplied in truck and trailer bodies, signs, and various automotive components where weight reduction is important.

Machining Capabilities

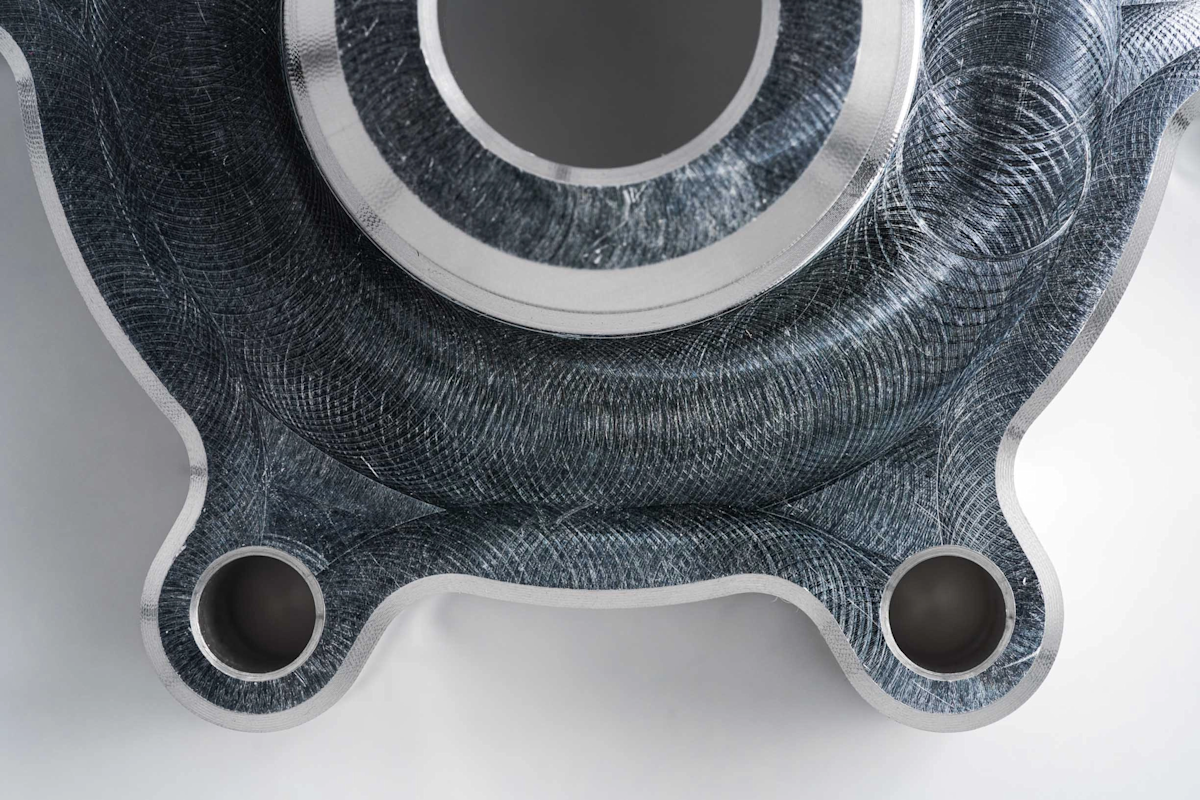

BZ Metal Products has extensive experience in machining Aluminum 5052. Our advanced equipment and skilled technicians ensure precision parts with excellent finishes.

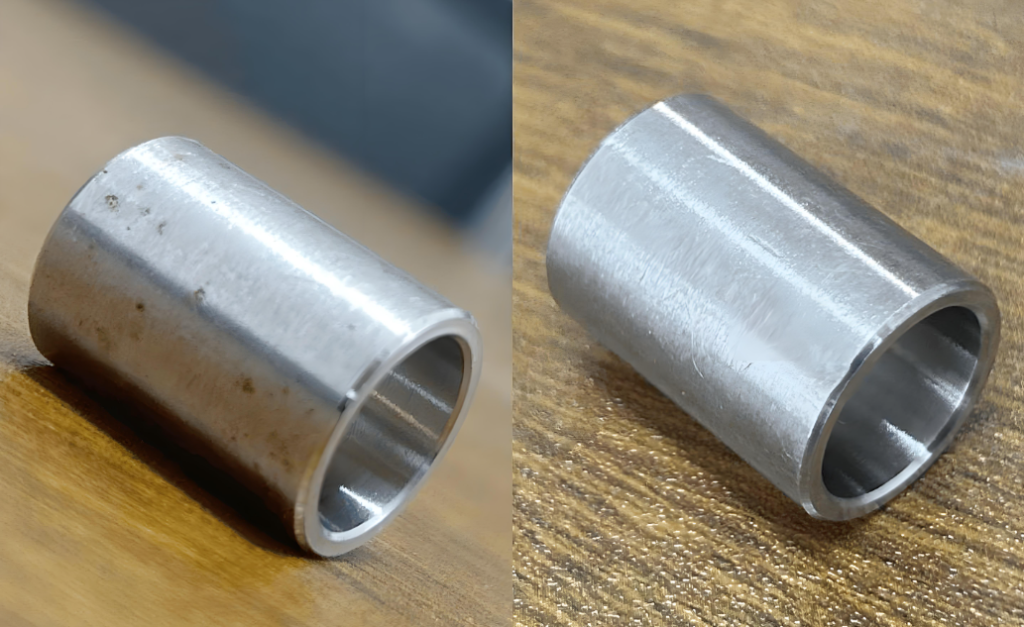

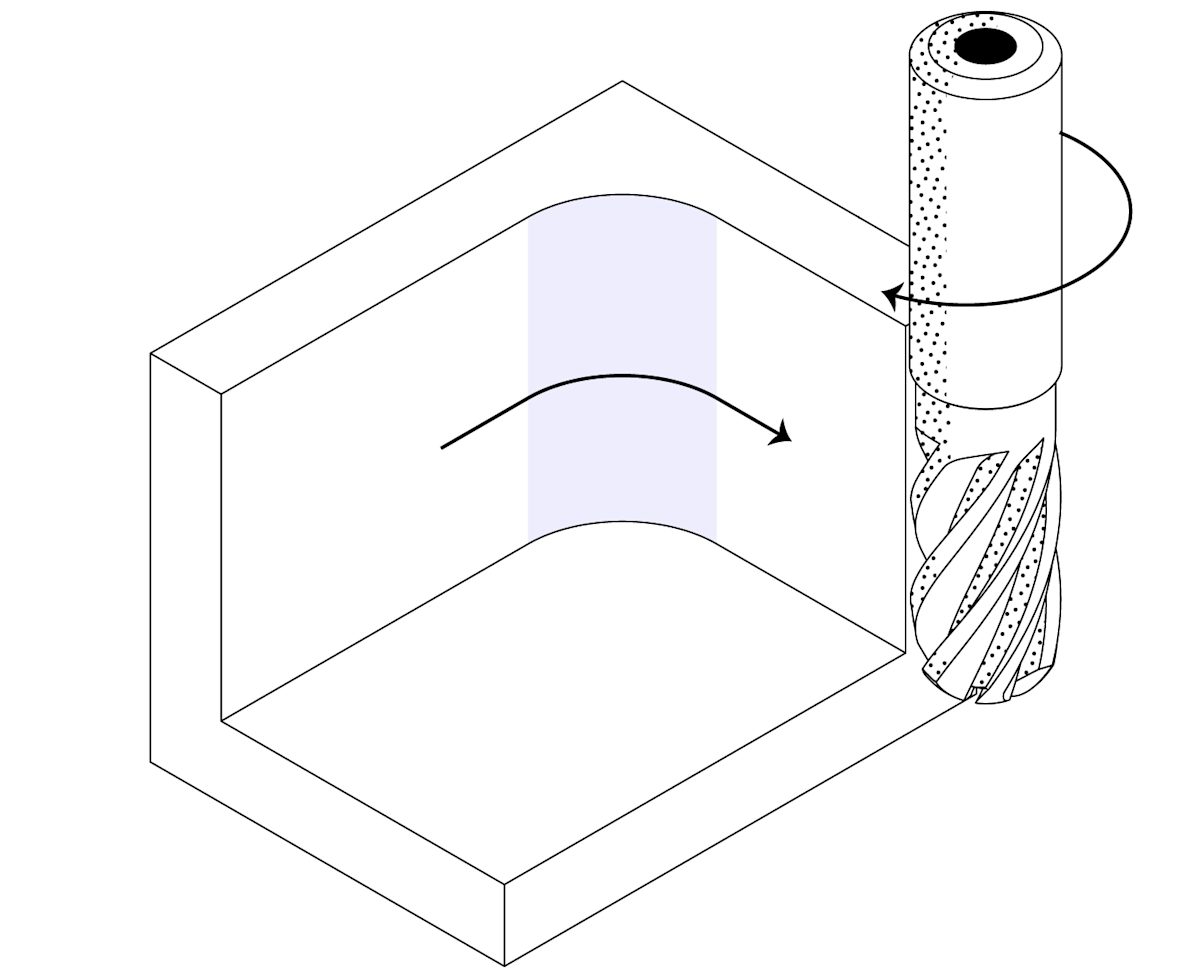

CNC Machining Process

Aluminum 5052 offers excellent machinability, with a rating of approximately 90% that of free-cutting aluminum alloys. It can be effectively machined using a variety of techniques, producing precision components with excellent surface finishes.

At BZ Metal Products, we use advanced 3-axis and 5-axis CNC machining centers to produce complex components from Aluminum 5052 with tight tolerances and exceptional accuracy.

Design Preparation

We review your CAD files and prepare them for CNC machining, optimizing toolpaths for efficient production and high accuracy.

Material Selection

The appropriate temper of Aluminum 5052 is selected based on your application requirements and specifications.

CNC Machining

Using advanced CNC milling or turning equipment, we machine your Aluminum 5052 parts with precision, following the programmed toolpaths for accurate material removal.

Surface Finishing

After machining, your parts can undergo various finishing processes including anodizing, bead blasting, polishing, or painting to enhance appearance and durability.

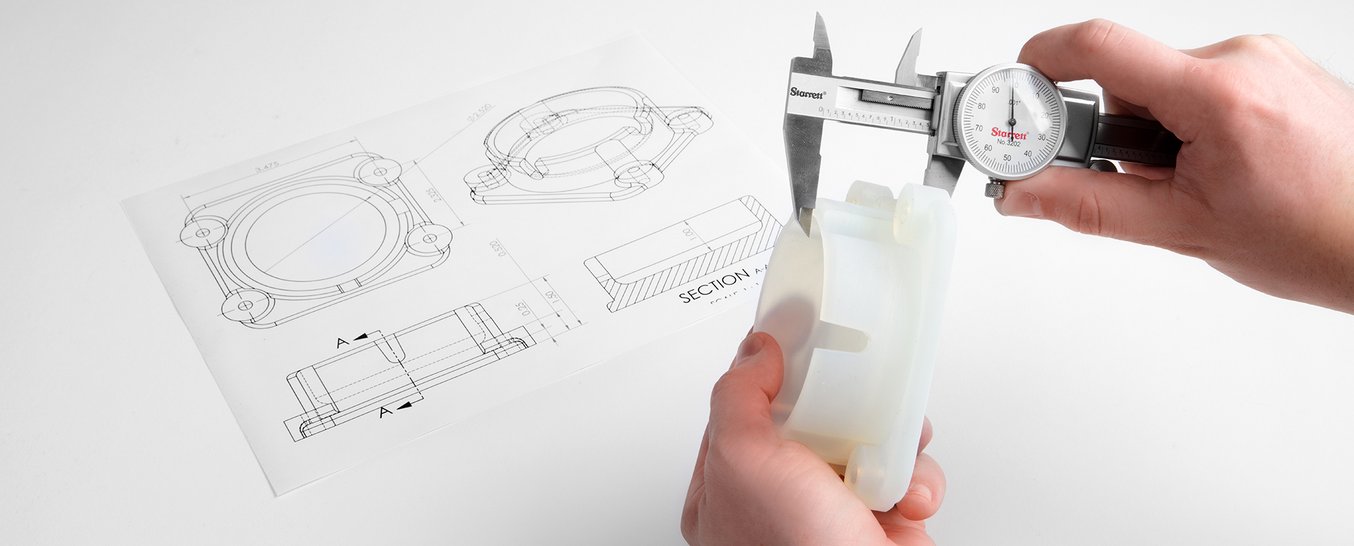

Quality Control

All Aluminum 5052 parts undergo rigorous inspection using precision measurement equipment to ensure they meet your exact specifications and quality standards.

Tolerance

Our CNC machining equipment can achieve tight tolerances for Aluminum 5052 parts, ensuring precise fit and function in your applications.

Maximum Dimensions

We can machine Aluminum 5052 parts up to these dimensions, with larger sizes available through our multi-part assembly capabilities.

Minimum Wall Thickness

Our precision machining processes can achieve thin-walled features down to 0.5 mm in Aluminum 5052, providing lightweight yet strong components.

Surface Finish

We can produce excellent surface finishes on Aluminum 5052, from standard machined finishes to near-mirror polishing.

Thread Features

Precision threading capabilities for Aluminum 5052 parts, including tapped holes, threaded standoffs, and other threaded features.

Batch Sizes

From single prototypes to high-volume production runs, our CNC machining services for Aluminum 5052 are scalable to your needs.

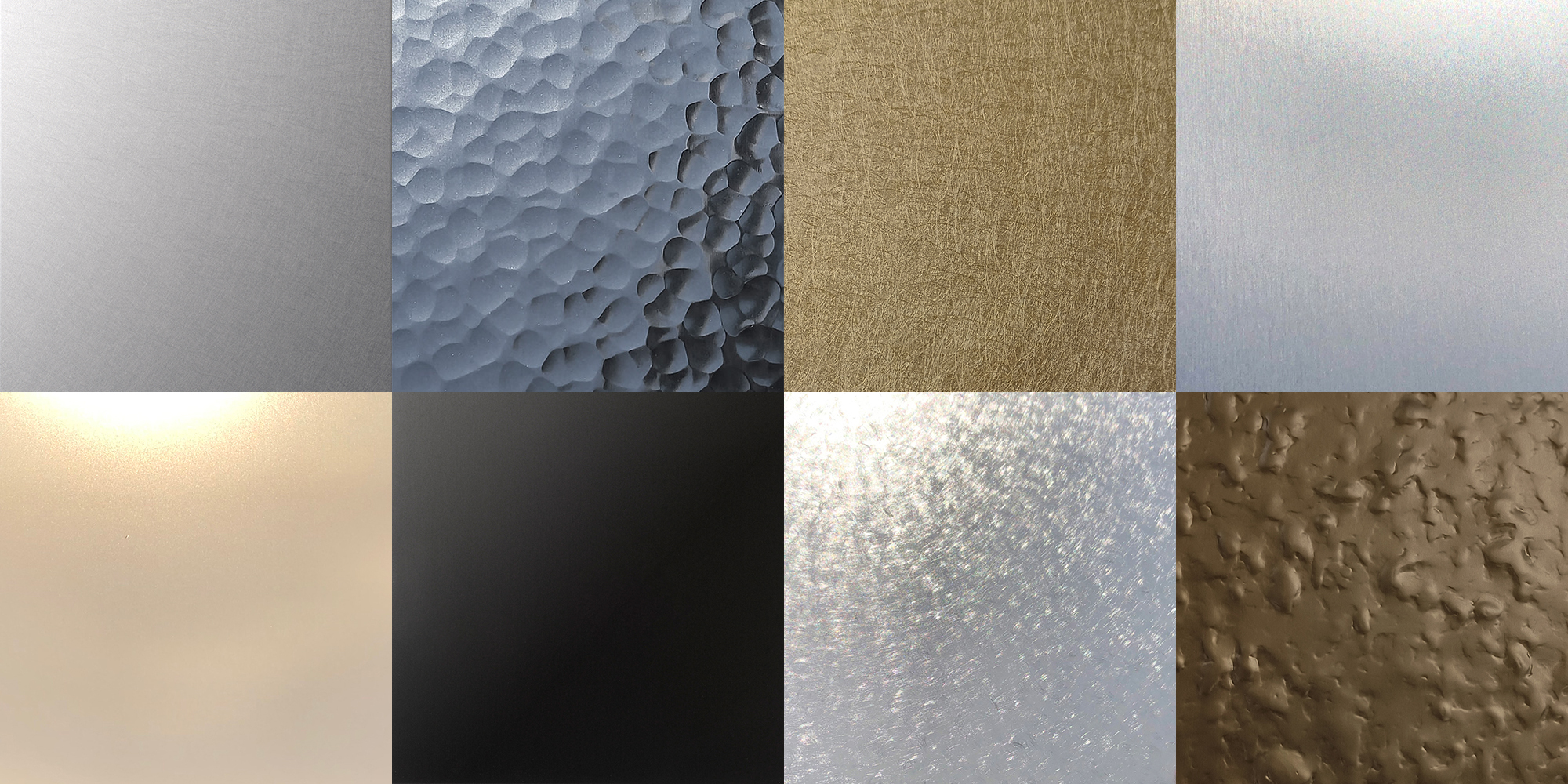

Surface Finishing Options

Enhance the appearance, durability, and performance of your Aluminum 5052 parts with our range of high-quality surface finishing options.

Anodizing (Type II)

A decorative and protective electrochemical process that creates a durable oxide layer, available in various colors. Offers good corrosion resistance and wear protection.

Learn more

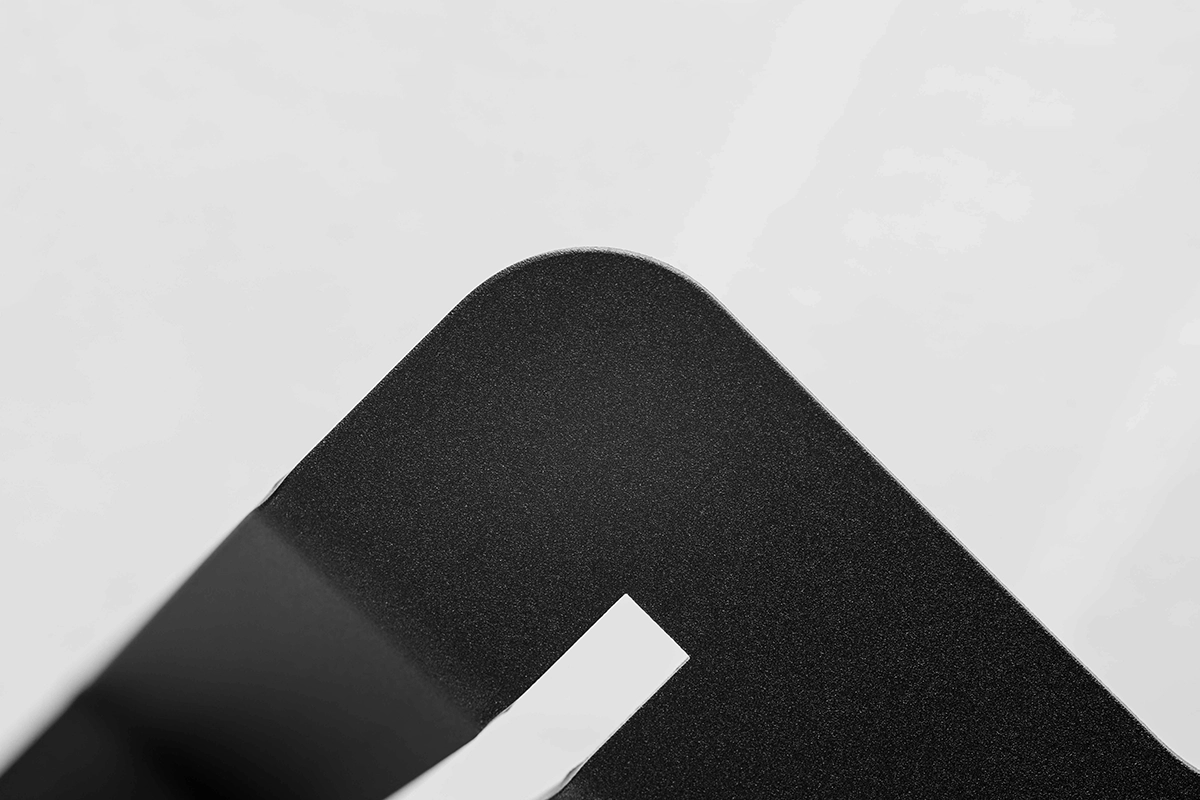

Bead Blasting

Creates a uniform matte finish by propelling fine glass beads at the surface. Excellent for removing tool marks and creating an even, non-reflective appearance.

Learn more

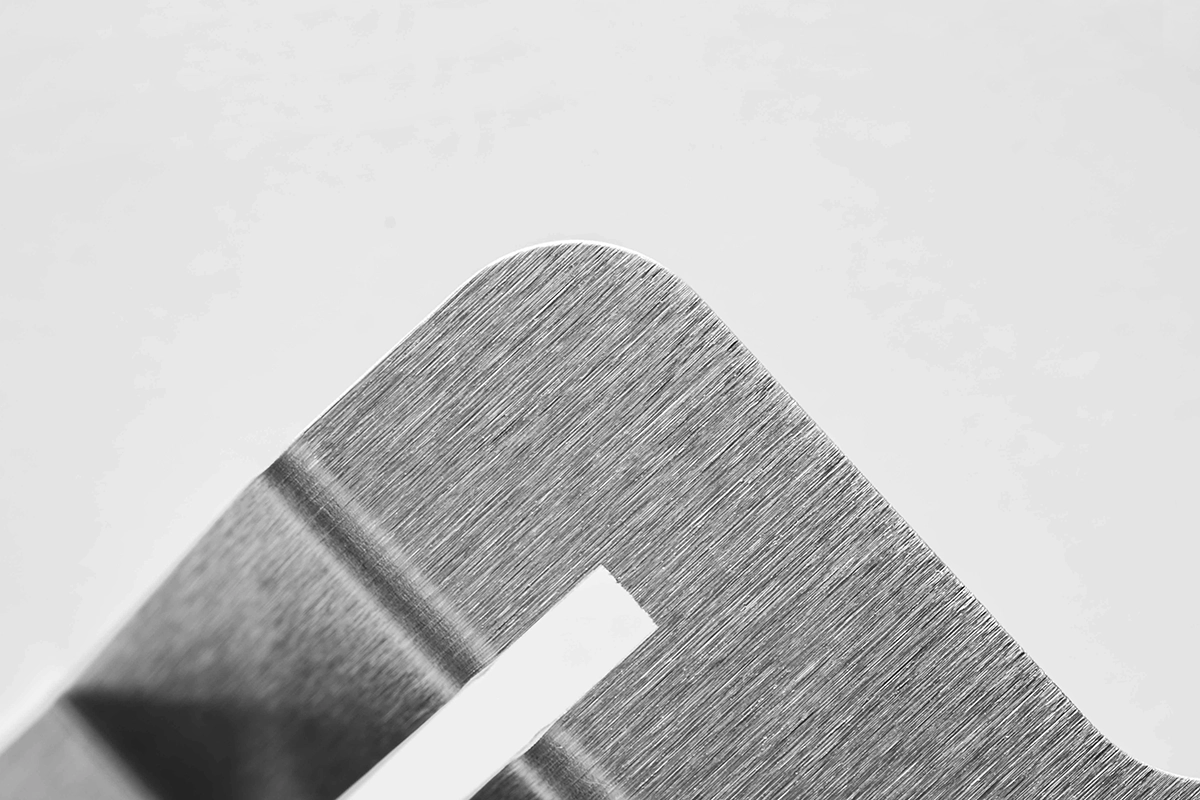

Polishing

Mechanical or chemical polishing produces a highly reflective, mirror-like surface finish. Ideal for aesthetic applications or where smooth surfaces are required.

Learn more

Powder Coating

Applies a thick, durable finish available in countless colors and textures. Provides excellent corrosion protection and impact resistance for exterior applications.

Learn more

Brushed Finish

Creates a satin-like directional texture that reduces the visibility of fingerprints and scratches. Popular for architectural and aesthetic applications.

Learn more

Wet Painting

Traditional painting creates a smooth, uniform color with good protection. Available in virtually any color with various gloss levels and specialized coatings.

Learn more

Chemical Conversion

Also known as Alodine or chromate conversion, this treatment enhances corrosion resistance and provides a good base for paint adhesion.

Learn more

As Machined

The natural finish directly from the CNC machine, with visible tool marks. Cost-effective for non-aesthetic applications or where further processing is planned.

Learn moreCustom Finishing Solutions

Not sure which finish is right for your Aluminum 5052 parts? Our finishing experts can recommend the optimal surface treatment based on your specific application requirements, environmental conditions, aesthetic preferences, and budget constraints. We can also develop custom multi-stage finishing processes for specialized applications. Contact us to discuss your project needs.

Design Guide for Aluminum 5052

Optimize your designs for Aluminum 5052 CNC machining with these practical tips and recommendations for better quality, reduced costs, and improved manufacturability.

Designing for Machinability

Aluminum 5052 offers excellent machinability, but proper design considerations can help you achieve better results, reduce costs, and ensure your parts meet both functional and aesthetic requirements.

The following design guidelines will help you optimize your components for CNC machining in Aluminum 5052, taking advantage of the material's properties while avoiding common pitfalls.

Wall Thickness

Maintain a minimum wall thickness of 0.8mm for standard parts and 0.5mm for precision features. Thinner walls can cause vibration during machining and may lead to distortion or dimensional inaccuracies.

Internal Corners

Design internal corners with a radius of at least 1/3 the depth of the pocket. Sharp internal corners require additional machining time and tool changes, increasing costs and production time.

Hole Dimensions

For through holes, maintain a minimum diameter equal to the hole depth divided by 4. For blind holes, the depth should not exceed 4 times the diameter to avoid tool breakage and ensure accuracy.

Thread Engagement

For tapped holes in Aluminum 5052, ensure thread engagement is at least 1.5 times the diameter to provide adequate strength. Consider thread inserts for high-stress applications.

Deep Pockets

For deep pockets, design with a slight draft angle (1-3°) to facilitate machining and improve surface finish. This reduces machining time and produces better results.

Tolerances

Specify tight tolerances (±0.05mm) only where functionally necessary. Aluminum 5052 can achieve high precision, but overly tight tolerances increase cost without adding value.

Need Help with Your Design?

Our engineering team can review your designs and provide recommendations specific to your Aluminum 5052 components. We offer design for manufacturability (DFM) analysis to help optimize your parts for quality, cost, and performance.

Related Materials & Resources

Explore other aluminum alloys and helpful resources for your CNC machining projects with BZ Metal Products.

Aluminum 6061

The most popular aluminum alloy, offering excellent machinability, good strength, and natural corrosion resistance. Widely used across industries.

Aluminum 7075

High-strength aerospace grade aluminum with excellent fatigue resistance and mechanical properties comparable to many steels.

Aluminum 5083

Higher strength than 5052 with excellent corrosion resistance in marine environments. Good weldability and moderate machinability.

Aluminum 2024

High-strength alloy with excellent fatigue resistance, commonly used in aircraft structures and other high-stress applications.

CNC Machining Design Guide

Comprehensive guide to designing parts for CNC machining, covering material selection, feature design, tolerances, and cost optimization.

Download Guide

Aluminum Surface Finishes

Detailed comparison of different surface treatments for aluminum, including anodizing, painting, powder coating, and mechanical finishes.

View Guide

Tolerance & Accuracy Guide

Learn about achievable tolerances in CNC machining of aluminum alloys and how to specify them correctly for your engineering applications.

Read MoreReady to Start Your CNC Machining Project?

Contact us now for a free quote and professional advice