Custom Automotive Parts Manufacturing

Partner with BZ Metal Products to accelerate innovation in your automotive projects. From prototypes to production parts, we deliver precision-engineered components that meet the highest industry standards.

Get Instant QuoteQuality Documentation

- CMM Inspection Reports

- Material Test Reports

- Certificates of Conformance

- First Article Inspections

Quality Standards

- Precision Measurement

- Strict Quality Control

- Advanced Testing Equipment

- 100% Part Inspection

Automotive Manufacturing Capabilities

From prototyping to production, we deliver high-quality components for the automotive industry.

Prototyping is a crucial step in developing automotive technology, and definitely not when you want to be waiting around for parts. Whether you need a few complex parts or several thousand, our team can deliver components in days. We can also scale from prototyping to small batch production quickly and deliver parts to stand in for First Off Tools (FOTs) while you're still looking for a serial supplier.

CNC Machining

Precision CNC milling and turning for complex automotive components with tight tolerances.

- Tolerances down to ±0.020 mm

- 5-axis machining capability

- Lead times from 5 business days

- Automotive-grade materials

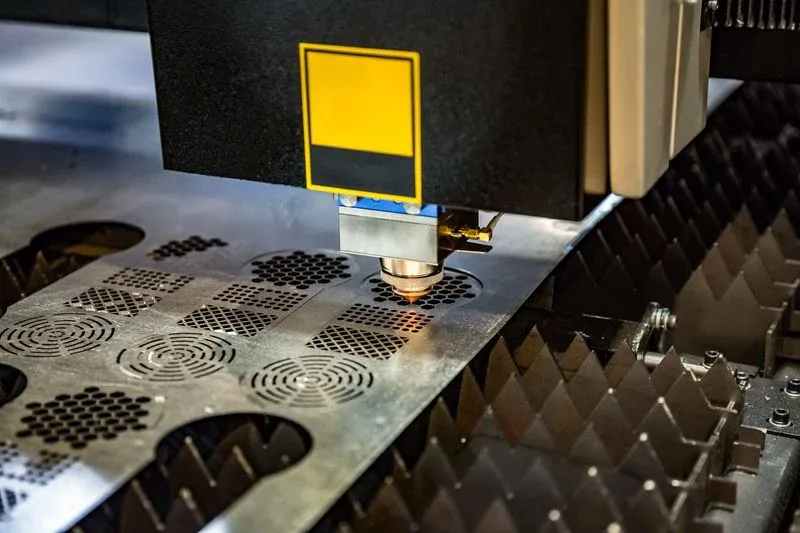

Sheet Metal Fabrication

Advanced sheet metal fabrication services for structural components and panels.

- Precision laser cutting

- Complex forming and bending

- Tolerances down to ±0.1 mm

- Lead times from 5 business days

Injection Molding

Prototypes and production tooling for plastic automotive components.

- Wide range of part complexities

- 1 to 100,000+ parts

- Various automotive-grade polymers

- Precise, repeatable production

Surface Finishing

Comprehensive surface finishing solutions for automotive components.

- Anodizing Type II & III

- Powder coating

- Plating options

- Texturing and polishing

How Automotive Companies Use Our Services

We support automotive manufacturers and suppliers with custom components for a wide range of applications.

Electric Vehicles

Custom components for electric vehicle systems, from battery enclosures to charging equipment.

- Battery enclosures

- Thermal management components

- Charging connectors

- Lightweight structural parts

Autonomous Systems

Precision components for sensor mounting, control systems, and testing equipment.

- Sensor housings

- Camera mounts

- Control unit enclosures

- Testing apparatus

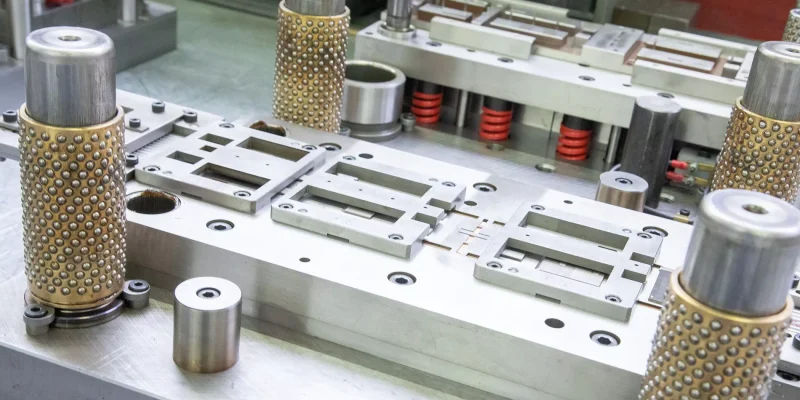

Manufacturing Tooling

Custom jigs, fixtures, and tooling solutions for automotive production lines.

- Assembly fixtures

- Inspection gauges

- Robotic end effectors

- Production line tooling

Materials & Surface Finishes

We provide a wide range of materials and surface finishes to meet the demanding requirements of automotive applications.

Automotive Materials

Steel & Stainless Steel

- 304/304L

- 316/316L

- 4140

- Tool Steels

Aluminum

- 6061-T6

- 7075-T651

- 5052-H32

- 2024

Engineering Plastics

- ABS

- Polycarbonate (PC)

- Nylon (PA6, PA66)

- POM (Delrin)

Specialty Materials

- Titanium Alloys

- PEEK

- Carbon Fiber Composites

- Inconel

Surface Finishes

Anodizing

- Type II

- Type III (Hard)

- Colored Anodizing

- Clear Anodizing

Plating

- Zinc Plating

- Nickel Plating

- Chrome Plating

- Electroless Nickel

Powder Coating

- Textured Finishes

- Matte & Gloss Options

- Custom Colors

- High-Temperature Resistant

Mechanical Finishes

- Bead Blasting

- Polishing

- Brushed Finish

- Texture Mapping

Success Stories

Discover how we've helped leading automotive companies overcome manufacturing challenges and achieve their goals.

Lightweight EV Battery Housing

Designed and manufactured a lightweight aluminum battery housing for an electric vehicle startup, reducing weight by 30% while maintaining structural integrity.

Weather-Resistant Sensor Housing

Produced custom sensor housings for autonomous vehicle systems with complex internal features and IP67 water resistance requirements.

How We Help Automotive Companies Innovate

Our expertise and capabilities enable automotive manufacturers to overcome challenges and accelerate innovation.

Complex Geometries & Precision

Our manufacturing capabilities can achieve incredible geometric complexity with tight tolerances. No matter how complex your design is, we have the technology to produce it with exceptional mechanical and cosmetic properties. Our facilities include the latest CNC technologies, including 5-axis machines, to produce rapid prototypes and small batches of production parts with ease.

Rapid Quoting & Design Support

Time is almost never on your side when you need to innovate quickly. Instead of waiting weeks for quotes, we provide quick pricing and advanced DFM analysis. We can also help optimize your designs for manufacturability, reducing costs and improving quality. Our rapid response enables you to get your parts into production faster so you're never late for the automotive revolution.

Expertise & Industry Knowledge

Our automotive engineers and seasoned mechanics understand the unique requirements of the automotive industry. We know how parts are used across every facet of the automotive sector, from prototyping to production. We've been in the shop ourselves and understand that even the smallest thing can cause big delays. Our mission is to get you from concept to customer as seamlessly as possible.

Frequently Asked Questions

Find answers to common questions about our automotive manufacturing services and capabilities.

- CNC machined parts: 5-10 business days

- Sheet metal components: 5-10 business days

- Injection molded parts: 10-15 business days

- Components requiring multiple processes or special finishes: 10-15 business days

- Comprehensive incoming material inspection

- In-process quality checks with calibrated equipment

- CMM (Coordinate Measuring Machine) verification for critical dimensions

- Final inspection before shipping

- Detailed quality documentation, including material certifications, inspection reports, and certificates of conformance

- PPAP documentation when required

- Rapid prototyping for concept validation and testing

- Pre-production runs to verify manufacturing processes

- Low to medium volume production (hundreds to thousands of parts)

- High-volume production through our strategic manufacturing partners

Ready to Start Your Sheet Metal Project?

Contact us now for a free quote and professional advice