CNC Machining in Brass

Low friction, excellent electrical conductivity, golden appearance. Brass is a metal alloy with good machinability and excellent electrical conductivity. Ideal for applications that require low friction.

Order CNC Machined Brass Parts

Custom Brass Parts

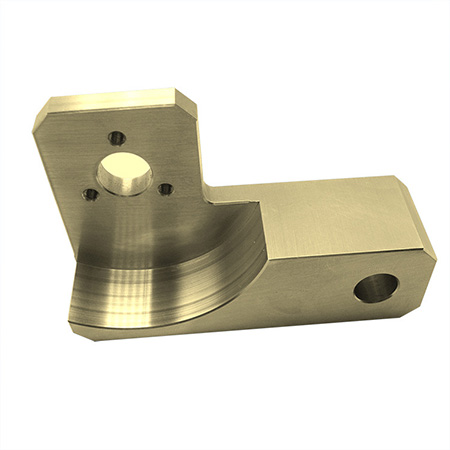

Brass is a versatile copper-zinc alloy that combines excellent machinability with durability and aesthetic appeal. With a beautiful golden appearance, brass offers superior electrical conductivity, low friction, and natural corrosion resistance, making it an ideal material for CNC machining across various industries.

BZ Metal Products' CNC machining services deliver precision brass components with tight tolerances and excellent surface finishes. Our capabilities include both 3-axis and 5-axis CNC milling, allowing us to create complex geometries for your most demanding applications in electrical engineering, plumbing, automotive, and decorative industries.

Excellent Conductivity

High electrical and thermal conductivity make brass ideal for electrical components and heat exchangers

Corrosion Resistant

Natural resistance to corrosion makes brass suitable for environments where exposure to moisture is expected

Highly Machinable

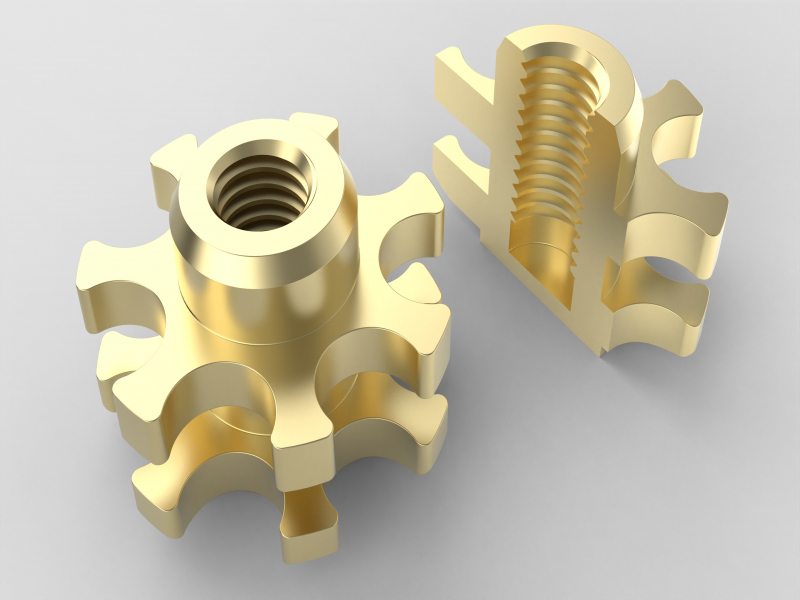

Brass is one of the easiest metals to machine, allowing for complex geometries and fine details with tight tolerances

CNC Machining Brass Materials

BZ Metal Products offers high-quality brass alloys for CNC machining. Our brass materials provide excellent machinability, electrical conductivity, and corrosion resistance for your precision components.

Brass C360

2.0375 | CuZn36Pb3 | 319 grade 2

Brass C360 is a highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction and excellent electrical conductivity.

Brass Cz121

C38500 | 2.0401 | CuZn39Pb3

Brass CZ121 is a free-cutting brass with excellent machinability due to its lead content. Offers good strength, wear resistance, and corrosion resistance for precision parts.

Additional Brass Grades Available by Request

Brass C260 (Cartridge Brass)

70% copper, excellent formability, moderate strength

Brass C353 (High Leaded Brass)

Superior machinability, pressure tightness, moderate strength

Naval Brass C464

Excellent corrosion resistance in marine environments

Brass Properties Overview

| Property | Brass C360 | Brass Cz121 | Units |

|---|---|---|---|

| Tensile Strength | 385 | 395 | MPa |

| Yield Strength | 310 | 325 | MPa |

| Elongation | 15 | 12 | % |

| Hardness (Brinell) | 110 | 115 | HB |

| Modulus of Elasticity | 97 | 100 | GPa |

| Machinability (relative to free-cutting brass) | 100 | 100 | % |

| Property | Brass C360 | Brass Cz121 | Units |

|---|---|---|---|

| Density | 8.5 | 8.4 | g/cm³ |

| Melting Point | 885-900 | 890-905 | °C |

| Thermal Conductivity | 115 | 120 | W/m·K |

| Electrical Conductivity (relative to copper) | 26 | 28 | % IACS |

| Coefficient of Thermal Expansion | 20.5 | 20.3 | μm/m·K |

| Specific Heat Capacity | 380 | 375 | J/kg·K |

| Element | Brass C360 | Brass Cz121 |

|---|---|---|

| Copper (Cu) | 61.5-64.5% | 57.0-59.0% |

| Lead (Pb) | 2.5-3.5% | 2.5-3.5% |

| Iron (Fe) max | 0.35% | 0.30% |

| Zinc (Zn) | Balance | Balance |

| Aluminum (Al) max | 0.15% | 0.05% |

Characteristics & Applications

Excellent Machinability

Brass is among the most machinable of all metals, resulting in excellent surface finishes and tight tolerances. The addition of lead (in leaded brasses like C360) further enhances machinability.

Electrical & Thermal Conductivity

While not as conductive as pure copper, brass still offers excellent electrical and thermal conductivity, making it ideal for electrical components, connectors, and heat exchangers.

Corrosion Resistance

Brass naturally resists corrosion in standard atmospheres and freshwater environments. It forms a protective patina that prevents further corrosion, though it may not be suitable for marine environments without special treatment.

Low Friction Properties

Brass has naturally low friction characteristics, making it excellent for applications with moving parts such as gears, bearings, lock components, and valves.

Brass CNC Machining Services

BZ Metal Products offers complete brass CNC machining services from prototyping to production. Our expertise in working with brass allows us to produce complex components with excellent precision and surface finish.

Expert Brass Machining

Our team specializes in brass machining with years of experience working with various brass alloys. We understand the unique machining characteristics of brass and optimize our processes to achieve superior surface finishes and tight tolerances.

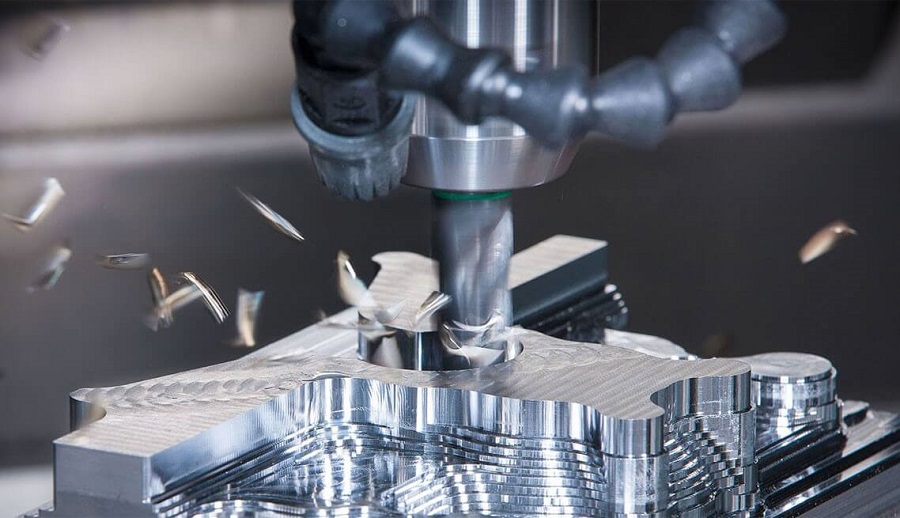

Advanced CNC Equipment

We utilize the latest 3-axis and 5-axis CNC milling and turning centers specifically configured for brass machining. Our advanced equipment allows us to produce complex geometries and intricate details with exceptional precision.

Finishing Options

We offer a variety of surface finishing options for brass including polishing, bead blasting, brushing, and plating. These finishes enhance both the appearance and performance of your brass components while providing additional protection.

Our Brass Machining Process

From design to delivery, our streamlined process ensures high-quality brass components that meet your exact specifications. We focus on efficiency and quality at every stage of production.

Design Upload

Upload your CAD file through our secure platform. Our system automatically analyzes your design for manufacturability and provides instant feedback.

Brass Alloy Selection

Choose from our range of brass alloys or receive expert recommendations based on your application requirements and performance needs.

Engineering Review

Our engineers review your design and provide feedback for optimizing manufacturability while maintaining design integrity and reducing costs where possible.

CNC Programming

Our programmers create optimized toolpaths specifically for brass machining, ensuring efficient material removal while maintaining excellent surface finishes.

Precision Machining

Your brass components are machined on our advanced CNC equipment with careful attention to detail. In-process inspections ensure quality at each step.

Finishing & Treatment

If specified, your parts receive surface finishing treatments to enhance appearance, durability, or performance characteristics according to your requirements.

Quality Inspection

All brass components undergo thorough inspection with precision measuring equipment to verify dimensions, tolerances, and surface quality before shipping.

Secure Packaging & Delivery

Your finished parts are carefully packaged to prevent damage and shipped via your preferred method with typical lead times under 10 days.

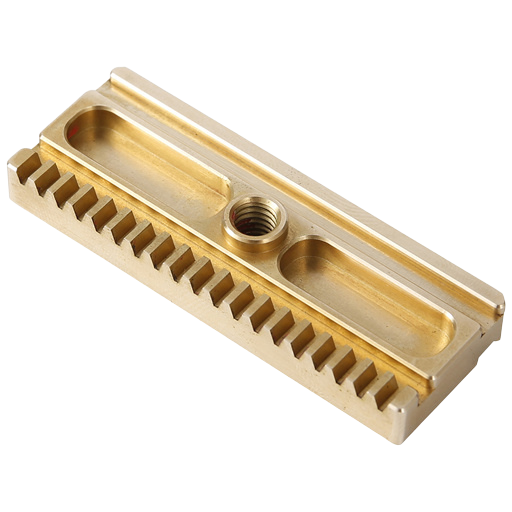

CNC Machining Specifications

Price

Competitive pricing with volume discounts available

Lead Time

Typically < 10 days (expedited options available)

Wall Thickness

Minimum 0.75 mm

Tolerances

Standard: ±0.125mm (±0.005″), Precision: ±0.05mm (±0.002″)

Max Part Size

250 x 200 x 100 mm

Surface Finish

As machined (standard), polished, brushed, plated

Common Applications for Brass Components

Brass CNC machined parts are ideal for a wide range of applications across multiple industries. Here are some common uses for our precision brass components:

Electrical

- Electrical connectors

- Terminal blocks

- Switch components

- Conductive fixtures

Plumbing

- Valves and fittings

- Fluid system components

- Precision nozzles

- Pressure regulators

Automotive

- Radiator components

- Fuel system parts

- Bearing housings

- Decorative trim

Marine

- Corrosion-resistant fittings

- Propeller components

- Navigation equipment parts

- Deck hardware

Aerospace

- Electrical connectors

- Hydraulic fittings

- Fuel system components

- Interior hardware

Electronics

- Heat sinks

- RF shields

- EMI shielding components

- Electronic housings

Frequently Asked Questions

What is brass and why use it for CNC machined parts?

Brass is a metal alloy composed primarily of copper and zinc, with lead often added to enhance machinability. It's a popular choice for CNC machined parts due to several advantageous properties:

- Excellent machinability: Brass is among the easiest metals to machine, allowing for complex geometries, fine details, and excellent surface finishes

- Electrical and thermal conductivity: While not as conductive as pure copper, brass offers very good electrical and thermal properties

- Corrosion resistance: Naturally resistant to many forms of corrosion and develops a protective patina

- Low friction properties: Makes it ideal for components with moving parts like gears, bearings, and valves

- Attractive appearance: Distinctive golden color that can be polished to a high shine for decorative applications

- Cost-effectiveness: More affordable than many other engineering metals while still offering excellent properties

These properties make brass an excellent choice for applications in plumbing, electrical, automotive, marine, and decorative industries where a combination of performance, appearance, and value is required.

What are the differences between brass grades and which one should I choose?

The main differences between brass grades relate to their composition, primarily the ratio of copper to zinc and the presence of other elements like lead. Here's a comparison of our most commonly used brass grades:

- Brass C360 (Free-Cutting Brass): Contains approximately 61.5-64.5% copper and 2.5-3.5% lead. Excellent machinability, good strength, and corrosion resistance. Best for: precision components, parts requiring complex machining.

- Brass Cz121 (Free-Cutting Brass): Contains approximately 57-59% copper and 2.5-3.5% lead. Similar to C360 but with slightly higher zinc content. Best for: general-purpose components requiring good machinability.

- Brass C260 (Cartridge Brass): Contains approximately 70% copper with no lead. More ductile and better for forming operations. Best for: parts requiring forming, bending, or stamping after machining.

- Naval Brass C464: Contains copper, zinc, and tin (1%). Superior corrosion resistance, especially in marine environments. Best for: marine applications or outdoor use.

When selecting a brass grade, consider these factors:

- How complex is the part geometry? (More complex parts benefit from free-cutting grades like C360)

- Will the part be exposed to corrosive environments? (Marine applications may require Naval brass)

- Are electrical properties important? (Higher copper content improves conductivity)

- Will the part contain threads or require good surface finish? (Lead content improves these aspects)

Our engineering team can provide guidance on selecting the optimal brass grade for your specific application requirements.

What tolerances can be achieved with brass CNC machining?

Brass is one of the most dimensionally stable and machinable metals, allowing for excellent tolerances. At BZ Metal Products, we can achieve the following tolerances for brass CNC machined parts:

- Standard tolerances: ±0.125mm (±0.005″)

- Precision tolerances: ±0.05mm (±0.002″)

- High-precision tolerances: Down to ±0.025mm (±0.001″) for critical features

Factors that may affect achievable tolerances include:

- Part geometry and complexity

- Overall part size (larger parts typically have wider tolerances)

- Feature type (holes, slots, etc.)

- Wall thickness (very thin walls may be more prone to distortion)

It's important to note that tighter tolerances generally increase machining time and cost. We recommend specifying precise tolerances only for critical features while allowing standard tolerances for non-critical dimensions to optimize cost-efficiency.

What surface finishes are available for brass parts?

We offer several surface finishing options for CNC machined brass parts:

- As-machined: The natural finish directly from CNC machining. Brass typically machines to a smooth finish with fine tool marks visible.

- Polished: Mechanical polishing to create a bright, reflective surface. Multiple grades available from semi-bright to mirror finish.

- Brushed: A directional satin finish that reduces glare while maintaining the brass appearance. Popular for architectural and decorative applications.

- Bead blasted: A uniform matte finish created by impacting the surface with fine glass beads. Provides a consistent appearance that hides minor imperfections.

- Clear coating: A protective clear lacquer that preserves the brass appearance and prevents tarnishing.

- Nickel plating: A bright silver-colored plating that provides additional hardness and corrosion resistance.

- Chrome plating: A highly reflective, hard surface finish that offers excellent wear and corrosion resistance.

- Gold plating: A thin layer of gold that enhances the appearance while improving conductivity and corrosion resistance.

The choice of surface finish depends on the functional requirements of your part (corrosion resistance, wear properties, electrical conductivity) as well as aesthetic considerations. Our team can recommend the optimal finish based on your application.

How should I design my part for brass CNC machining?

When designing parts for brass CNC machining, consider these design best practices:

- Wall Thickness: Maintain a minimum wall thickness of 0.75mm (0.03") to prevent warping or deformation during machining.

- Internal Corners: Design with a radius rather than sharp internal corners. We recommend a minimum radius of 1/3 the depth for internal corners.

- Deep Pockets: For deep pockets, maintain a reasonable depth-to-width ratio (typically less than 4:1) to allow proper tool access.

- Holes: For small holes, keep the depth-to-diameter ratio under 4:1. Standard drills can typically achieve a depth of 10x diameter, but precision decreases with depth.

- Threads: Internal threads should have a minimum of 3 full threads engaged for strength. External threads should have a minimum diameter of 0.8mm.

- Tolerances: Specify tight tolerances only on critical features and allow standard tolerances elsewhere to optimize cost.

- Surface Finish: Consider if any surfaces require specific finish callouts or if standard machined finish is acceptable.

- Text & Markings: For engraved text, maintain minimum letter height of 1mm and line width of 0.2mm for legibility.

Brass is highly machinable, which allows for more complex designs than many other metals. However, following these guidelines will help ensure your parts are manufacturable at the best possible quality and cost.

Get Your Brass Parts Into Production Today

Ready to bring your brass components to life? BZ Metal Products offers high-quality CNC machining services with competitive pricing and fast turnaround times. Our team of experts is ready to help you select the optimal brass alloy and manufacturing process for your specific requirements.