Metal CNC Machining

A wide range of metals for CNC machining, with applications in multiple industries. Ideal for both one-off prototypes and end-use custom parts.

Get an instant CNC machining quoteAll uploads are secure and confidential

Aluminum

High machinability and ductility, good strength-to-weight ratio.

Stainless steel

High tensile strength, corrosion and temperature resistant.

Mild steel

High machinability and weldability, high stiffness.

Brass

Low friction, excellent electrical conductivity, golden appearance.

Copper

Excellent thermal and electrical conductivity.

Alloy steel

High strength and toughness, fatigue resistant.

Tool steel

High hardness and stiffness, abrasion resistant.

Titanium

Excellent strength to weight ratio, used in aerospace, automotive and medical industries.

Inconel

High-strength and corrosion-resistant nickel alloy.

Need a specific metal or alloy not listed here? We can source thousands of specialized materials.

Contact us for special materialsMetal CNC Services

BZ Metal Products offers state-of-the-art CNC metal cutting services, guaranteeing consistent quality and fast turnaround times. With our advanced metal milling and metal turning machines, we provide consistent capacity and competitive pricing for all your manufacturing needs. We can fulfill low volume orders of CNC metal parts and handle complex CNC machining jobs, like CNC turning. With BZ Metal Products, you can produce complex prototypes and high volume production runs in a wide variety of metals and surface finish options.

Metal Machining

Metal machining is the process of cutting down a raw piece of metal to create a desired shape or object. This process is done most accurately with our CNC (Computerized Numerical Control) machines, which can produce almost any three dimensional object designed via CAD software. Our expert machinists mainly use 3- and 5-axis CNC machines for producing any metal parts that pass our quality checks.

Learn more about metal machining →

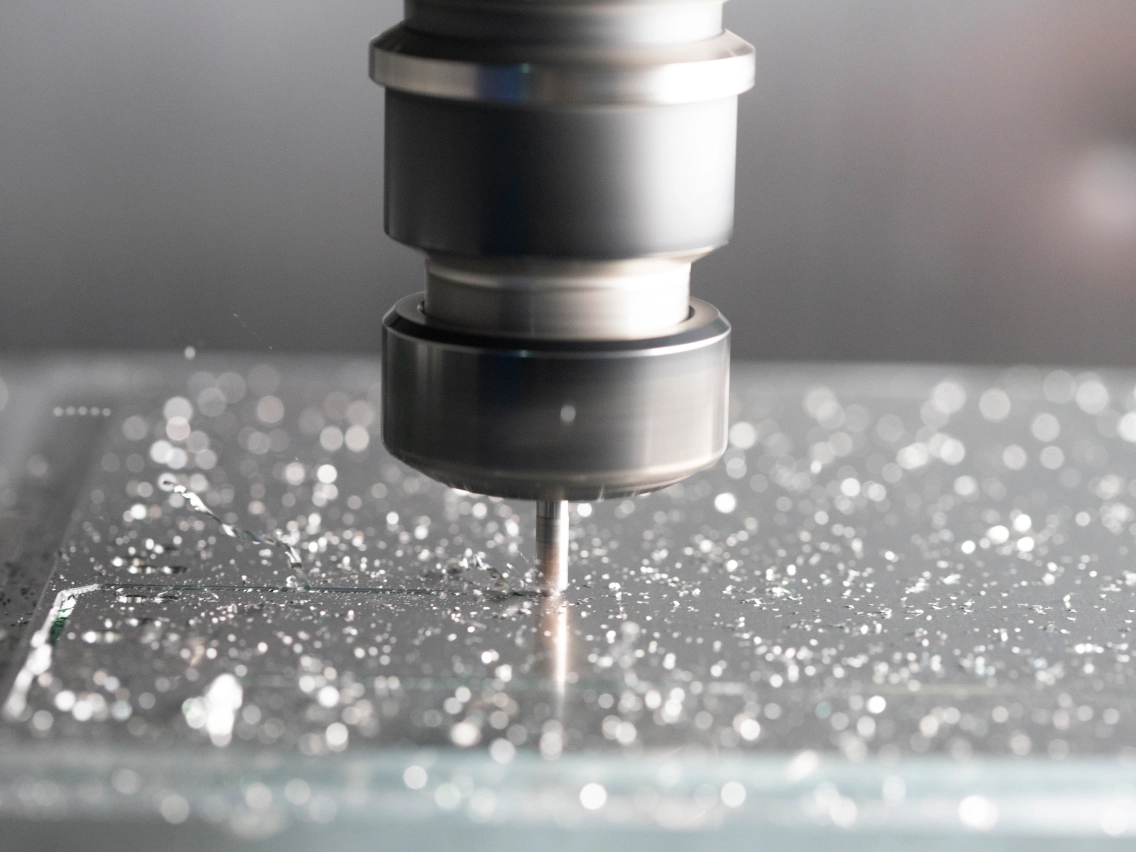

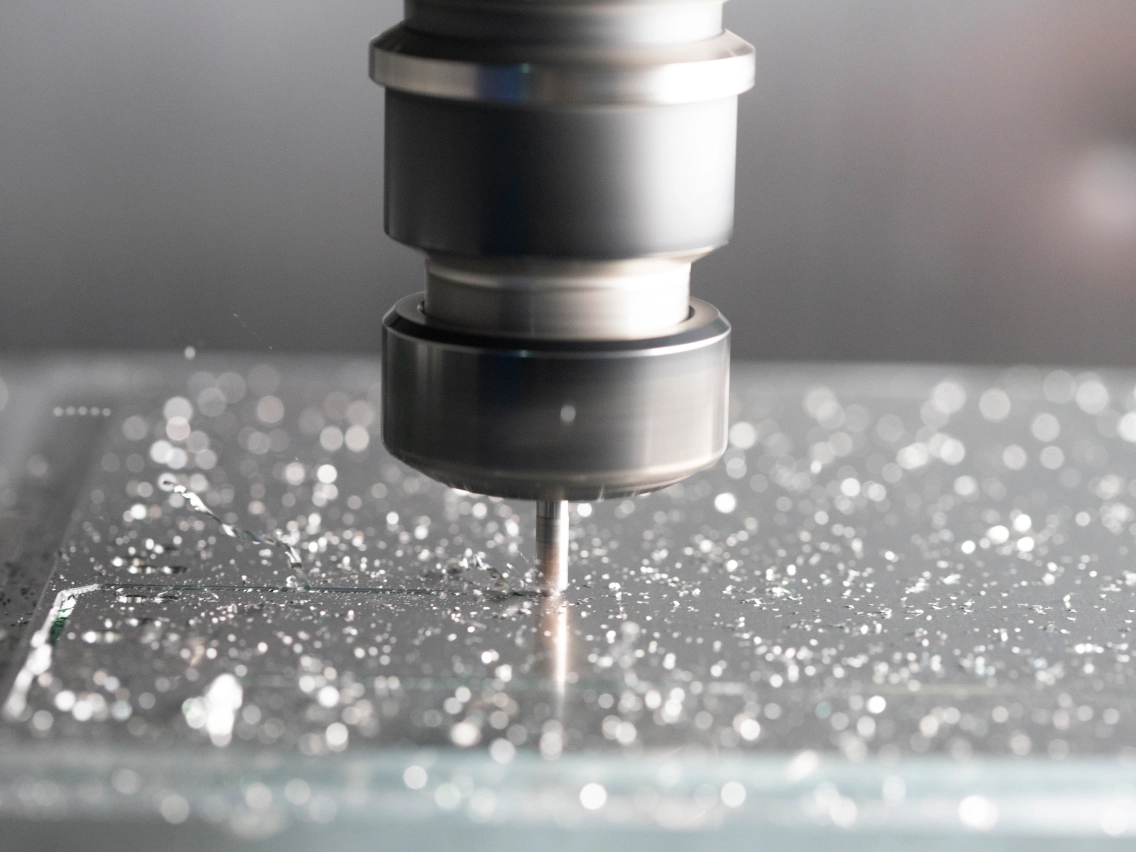

Metal Milling

Our CNC metal milling machines remove portions of metal from a raw block or sheet with precision cutting tools mounted to spindles rotating at high speeds. The cutting tools can be interchanged for different sizes depending on the material thickness or design complexity. The raw metal is secured to a work table that can rotate to allow the tool to reach many different angles.

Learn more about metal milling →

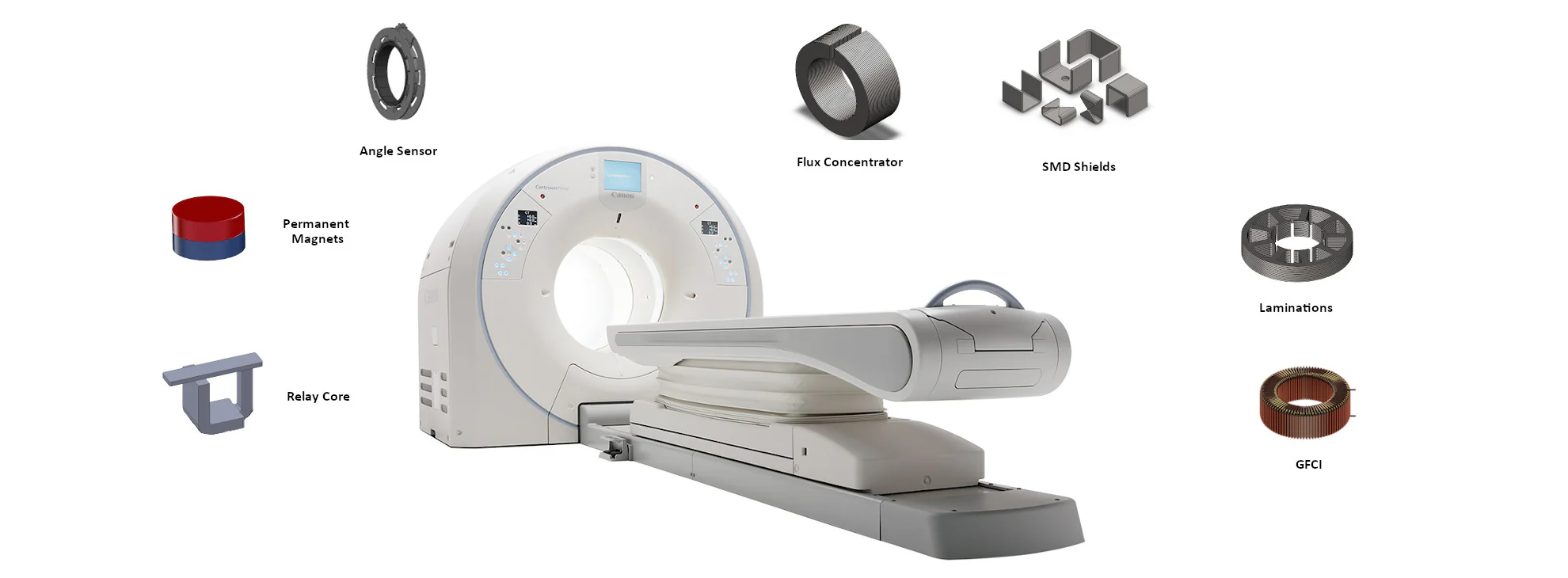

CNC Metal Fabrication

This process of CNC metal fabrication works excellently for shapes that can be machined from a single piece of metal. Our state-of-the-art metal CNC machines are able to cut complicated features on parts with great accuracy, while maintaining tight tolerances. This allows us to create complex geometries and precise components for various industries including aerospace, automotive, medical, and more.

Learn more about CNC fabrication →Frequently Asked Questions

Featured Metal CNC Projects

Explore some of our recent metal CNC machining projects across various industries.

Lightweight Titanium Brackets

Custom-designed titanium brackets for a satellite communications system, requiring exceptionally tight tolerances and significant weight reduction.

Surgical Instrument Components

Precision-machined components for minimally invasive surgical instruments, requiring biocompatible materials and flawless surface quality.

High-Performance Engine Components

Custom aluminum engine components for a high-performance racing team, requiring exceptional durability, heat resistance, and weight optimization.

Our Manufacturing Capabilities

BZ Metal Products offers comprehensive metal CNC machining services with advanced equipment and experienced machinists.

CNC Milling

Our advanced CNC milling machines can create complex parts with high precision, working with a wide range of metals from aluminum to titanium.

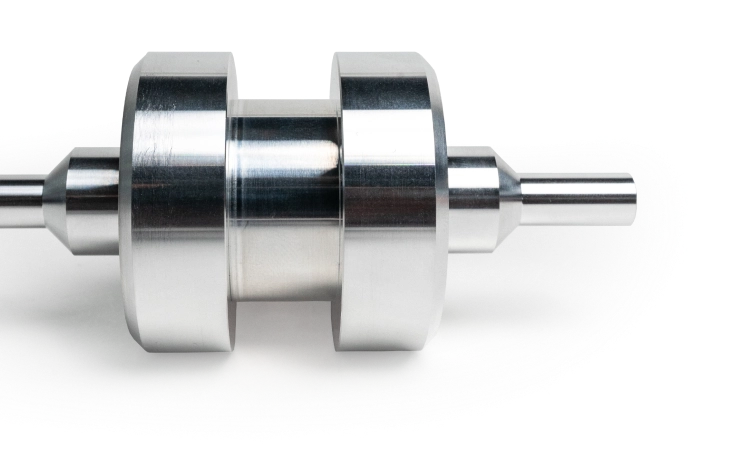

CNC Turning

Our CNC turning capabilities allow for the production of cylindrical parts with high precision, ideal for shafts, bushings, and other rotational components.

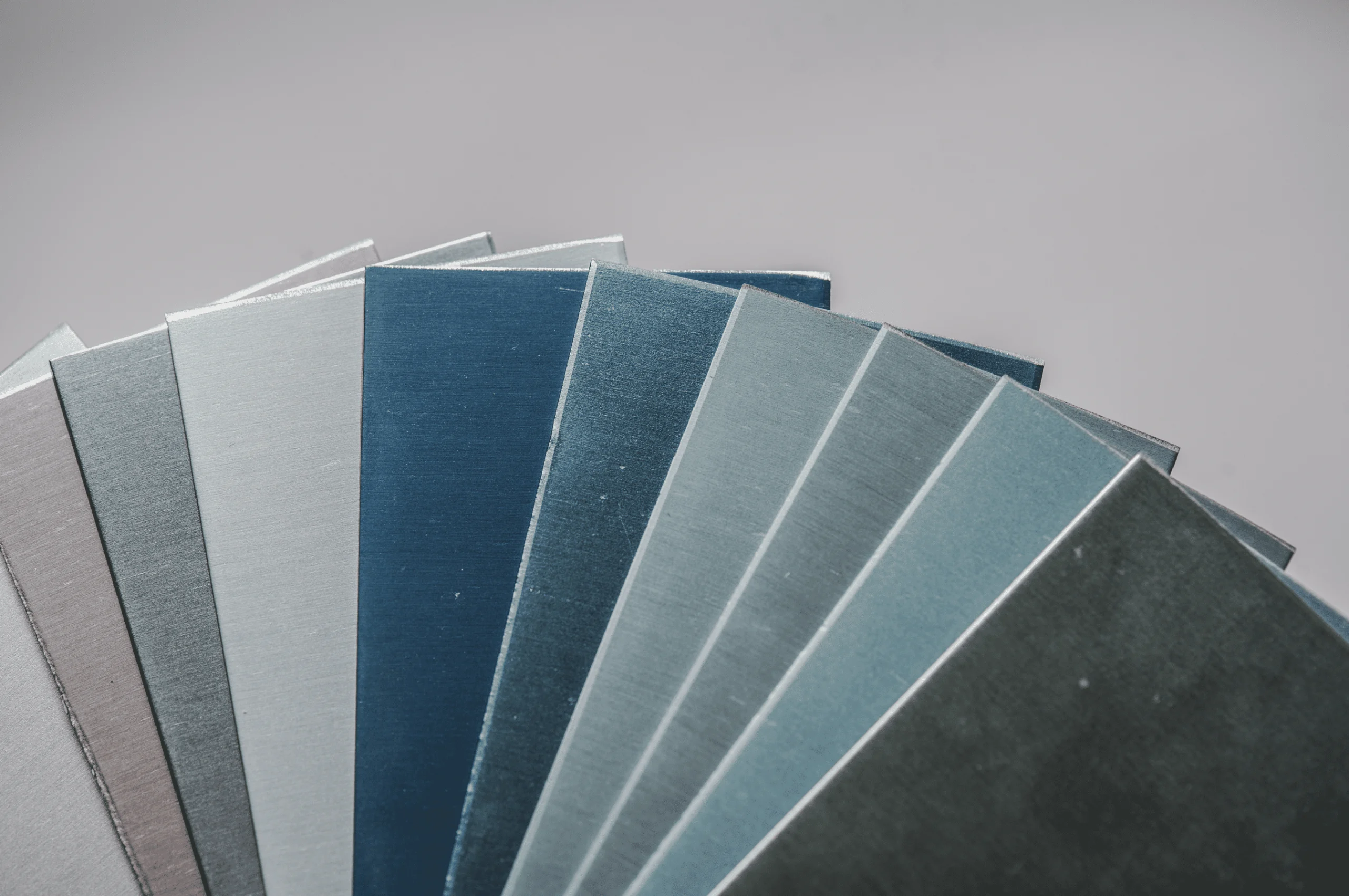

Wide Material Selection

We work with a comprehensive range of metals and alloys to meet your specific application requirements and performance needs.

Surface Treatments

We offer a wide range of finishing options to enhance the appearance, durability, and performance of your metal parts.