Source Custom Parts for Health Innovations

BZ Metal Products delivers high-precision components for medical devices and equipment, helping you bring life-changing healthcare innovations to market faster.

Get Instant Medical QuoteAll uploads are secure and confidential

Build Devices That Advance Patient Care

BZ Metal Products is the ideal solution for manufacturing custom parts for diagnostic and medical devices. Our advanced manufacturing capabilities fast-track product development, so you can prototype, innovate, and impact human lives, faster. Whether you're exploring the next biotech innovation, building devices for medical imaging or research, or need specialized components, our facilities have the precision manufacturing capacity you need.

Quality Documentation

- CMM Inspection Reports

- Material Test Reports

- Certificates of Conformance

- First Article Inspections

Quality Standards

- Precision Measurement

- Strict Quality Control

- Advanced Testing Equipment

- 100% Part Inspection

Medical Manufacturing Capabilities

Our advanced manufacturing processes ensure high-quality components for your medical devices and equipment.

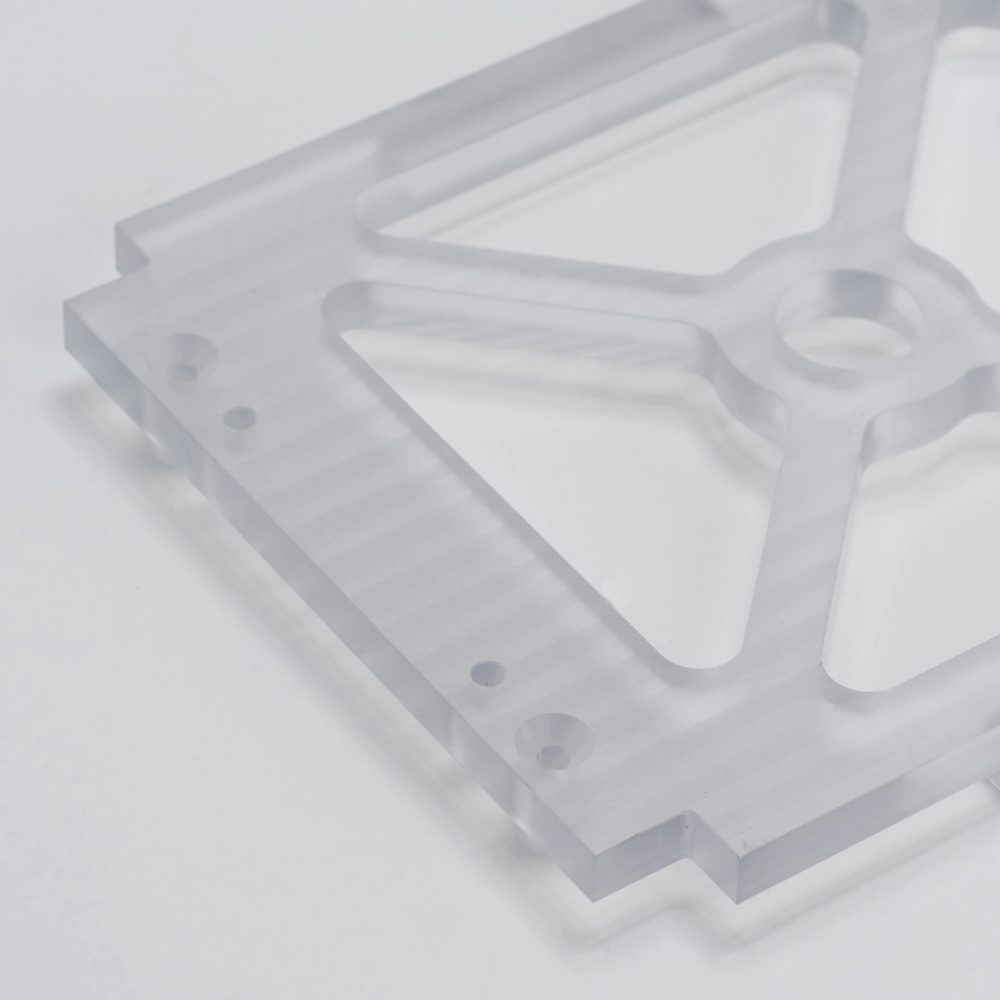

CNC Milling

For cost-efficient prototypes and production of complex medical components.

- 3-, 4- & 5-axis milling

- Lead times from 5 business days

- High precision for medical parts

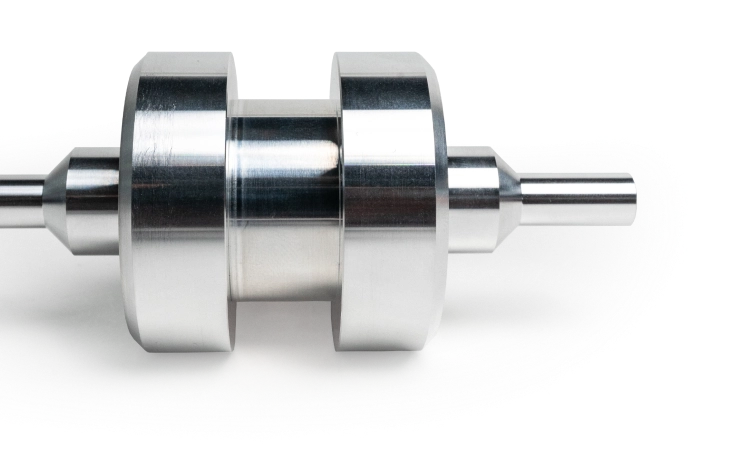

CNC Turning

Lathes and live tooling ideal for cylindrical medical components.

- 60+ metals & plastics

- Lead times from 5 business days

- Ideal for surgical tools

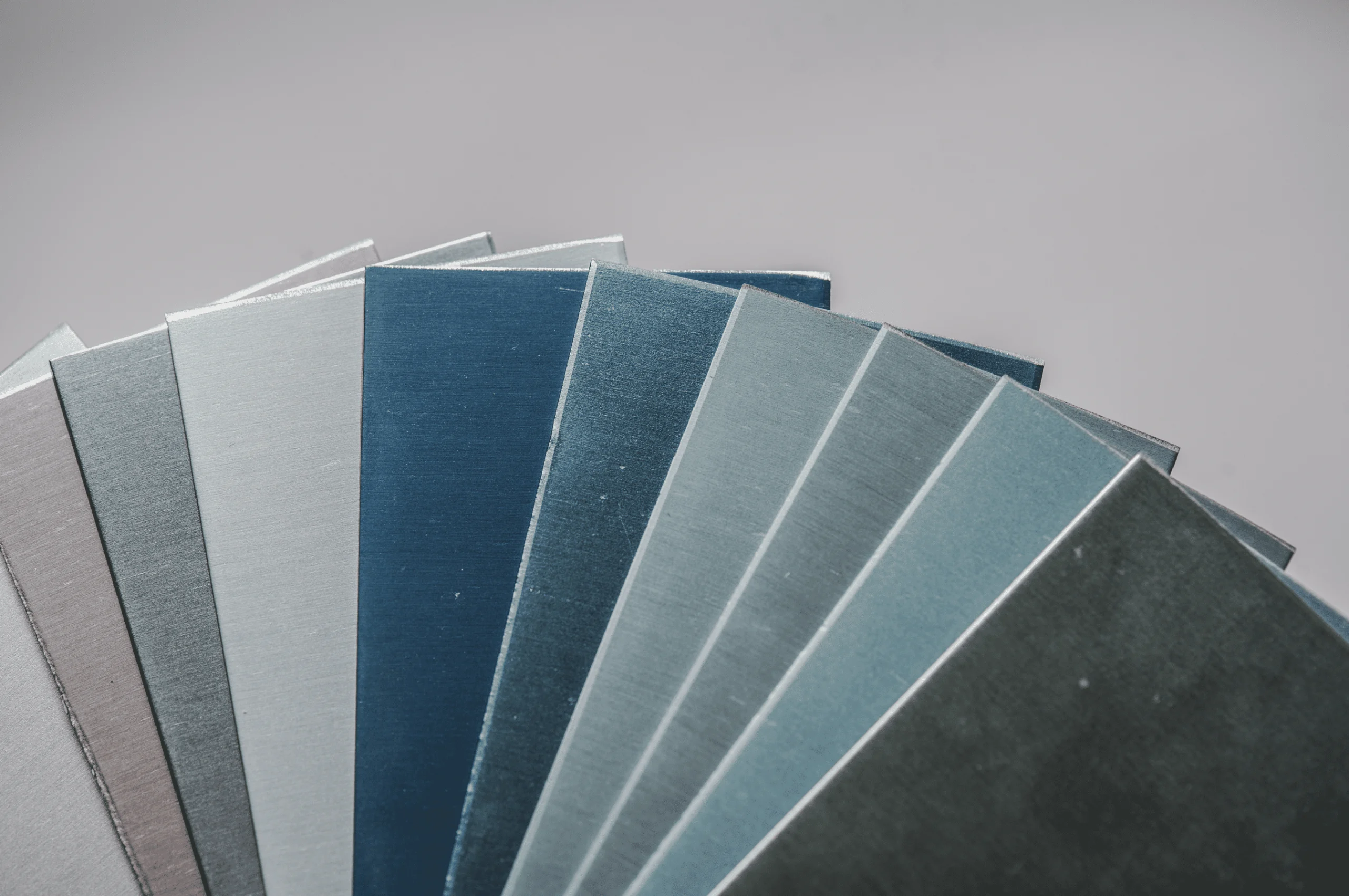

Surface Finishing

Premium finishes for aesthetic and functional requirements in consumer products.

- Anodizing, powder coating, plating

- Texturing and polishing

- Special cosmetic finishes

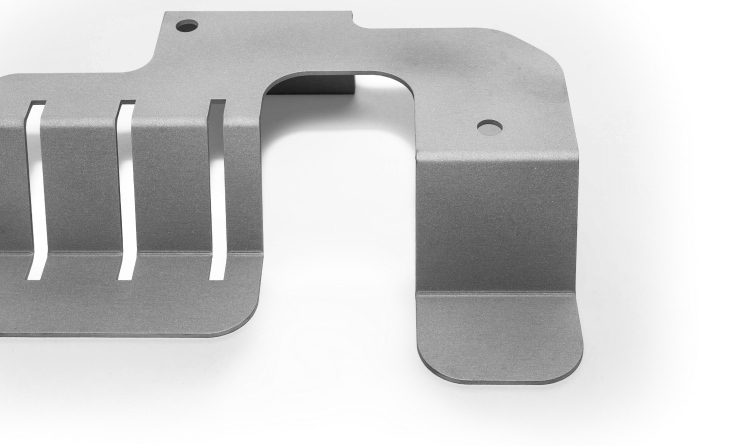

Sheet Metal Fabrication

Precision cutting and forming for medical equipment housings.

- Tolerances down to ±0.1 mm

- Lead times from 5 business days

- Medical-grade finishes

Why Healthcare Engineers Choose BZ Metal Products

We provide the expertise, quality, and reliability needed to bring innovative medical devices to market.

Specialized Manufacturing

Get access to cutting-edge capabilities and capacity for your medical devices, from precision prototypes to production volumes.

Learn More →

Quality Assurance

Our ISO 9001 and ISO 13485 certified quality management systems ensure reliable quality across all manufacturing processes.

Learn More →

Rapid Turnaround

Get competitive quotes with fast turnaround times, helping you bring medical innovations to market faster.

Learn More →Materials & Surface Finishes for Medical Parts

Through our advanced manufacturing capabilities, we provide access to a wide range of durable materials for medical applications.

Materials for Medical Devices

Select from more than 30 metal alloys and hundreds of industrial-grade plastics for your medical components.

Surface Finishes for Medical Devices

Improve durability and performance with a selection of finishes ideal for medical applications.

Need additional medical manufacturing services or specialty materials? Contact our medical device experts at medical@bzmetalproducts.com to discuss your specific requirements.

Gallery of Medical Parts

Explore our portfolio of high-precision components manufactured for medical devices and equipment.

How We Help Medical Companies Innovate

We provide the tools and expertise required to bring innovative medical devices to market faster and more efficiently.

Competitive Pricing, IP Protection & DFM Guidance

BZ Metal Products offers competitive pricing for comparing order volumes, lead times, materials, tolerances, secondary processes, and more for your medical projects. Get all final pricing information upfront, including shipping and quality control. We prioritize IP protection throughout the process to ensure that your designs and models are completely secure. Our engineering team is equipped with design for manufacturability (DFM) analysis capabilities and our mechanical engineers are always available to offer guidance to optimize your medical device designs.

To Spec and On Time, Every Time

To keep your supply chain consistent and reliable, we adhere to thorough quality control processes and protocols. Our manufacturing processes undergo complete validation before production begins, and on-site quality engineers perform frequent inspections to ensure they meet our high medical-grade standards. We inspect all parts for functionality and cosmetic specifications, and handle all quality documentation requirements to ensure on-time delivery. For medical device manufacturers, we understand that precision and consistency are non-negotiable, which is why our quality assurance processes are designed to meet the most demanding specifications.

Source Locally and Globally to De-Risk Supply Chains

Supply chain resilience is critical for medical manufacturers, especially when you need parts on a strict schedule and with specific certifications. We offer local and global sourcing options to reduce your supply chain risks and provide sourcing solutions to match your compliance requirements. BZ Metal Products gives you access to comprehensive manufacturing capabilities with consistent capacity available for your medical equipment projects, no matter the scope. Our network includes specialized manufacturers with expertise in medical-grade materials and finishes, ensuring your components meet all regulatory requirements.

Frequently Asked Questions

Find answers to common questions about our medical manufacturing services.

Ready to Start Your CNC Machining Project?

Contact us now for a free quote and professional advice