CNC Machining in Mild Steel

High machinability and weldability, high stiffness. Mild steels are low-carbon metal alloys offering good mechanical properties, machinability and weldability at low cost. Can be carburized to increased hardness.

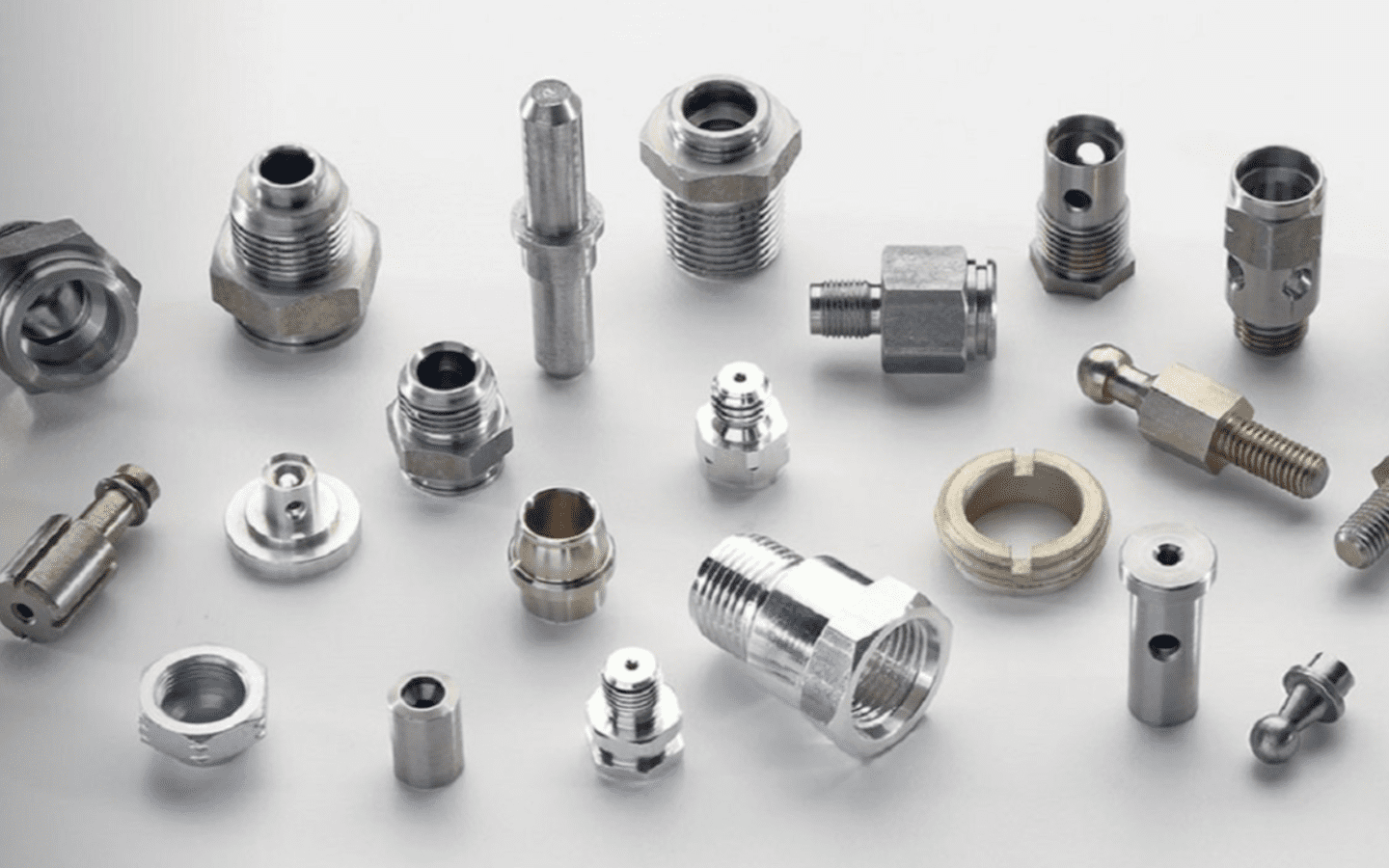

Order CNC Machined Mild Steel Parts

Custom Mild Steel Parts

Mild steel is a versatile, low-carbon steel that contains approximately 0.05–0.25% carbon, making it highly workable while maintaining good strength. Unlike higher carbon steels, mild steel is characterized by its exceptional machinability, weldability, and formability, allowing for efficient manufacturing of complex parts.

BZ Metal Products' CNC machining services enable you to create custom mild steel parts for various applications across industries including construction, automotive, machinery, industrial equipment, and general manufacturing. We offer precision machining of various mild steel grades, each with specific properties optimized for different applications.

Cost-Effective

Mild steel offers an excellent balance of mechanical properties and price, making it ideal for budget-conscious projects

Easy Processing

Excellent machinability, weldability, and formability make mild steel suitable for complex machined components

Material Versatility

We offer 7 different grades of mild steel, including 1018, 1045, S355J2, A36, and more to suit your project needs

CNC Machining Mild Steel Materials

BZ Metal Products offers a variety of high-quality mild steel grades for CNC machining. Each material has unique properties suitable for different applications.

Mild Steel 1018

1.1147 | C18 | 16Mn

Mild steel 1018 is a general-use alloy with good machinability, weldability, toughness, and strength. Susceptible to corrosion but offers excellent value.

Mild Steel 1045

1.0503 | C45 | EN8

Mild steel 1045 is a medium carbon steel with good weldability and machinability, high strength and good impact resistance. Susceptible to corrosion.

Mild Steel A36

1.0255 | Fe 410

Mild steel A36 is a common structural steel with good weldability. Suitable for a variety of industrial applications. Susceptible to corrosion.

Mild Steel S355J2

1.0577 | 1522H | Fe 510 D

S355J2 has a high tensile strength. Compared to other carbon steels, it has high electrical conductivity but low thermal conductivity and low ductility.

Additional Mild Steel Grades Available

Mild Steel S235JR

Good plasticity, toughness and weldability

Carbon Steel C45

Low thermal conductivity among wrought carbon steels

Mild Steel S275JR

Low strength with good machinability and weldability

Mild Steel Grade Comparison

| Property | MS 1018 | MS 1045 | A36 | S355J2 |

|---|---|---|---|---|

| Carbon Content | 0.14-0.20% | 0.43-0.50% | 0.25-0.29% | 0.23% max |

| Tensile Strength | 440 MPa | 570 MPa | 400-550 MPa | 510-680 MPa |

| Yield Strength | 370 MPa | 320 MPa | 250 MPa | 355 MPa |

| Machinability | Excellent | Good | Good | Moderate |

| Weldability | Excellent | Good | Excellent | Good |

| Common Applications | Shafts, pins, general parts | Gears, axles, bolts | Structural components | Bridges, pressure vessels |

Mild Steel CNC Machining Services

BZ Metal Products offers complete mild steel CNC machining services, producing complex parts with 7 different types of mild steel. Our expertise enables custom production for various industries with the highest quality standards.

Expert Machining

Our skilled technicians specialize in mild steel machining, understanding the unique characteristics of each grade to achieve optimal results. We maintain tight tolerances while ensuring excellent surface finishes on all mild steel components.

Complex Geometries

From simple brackets to intricate components with complex features, our advanced CNC equipment can machine mild steel to your exact specifications. Our 3-axis and 5-axis milling capabilities ensure we can produce virtually any geometry.

Surface Finishing Options

We offer various surface finishing options for mild steel parts including black oxide, zinc plating, powder coating, and painting to provide corrosion resistance and enhance aesthetics. Custom surface treatments are available to meet specific requirements.

Our Machining Process

BZ Metal Products employs a streamlined process for delivering high-quality mild steel parts that meet exact specifications. From quote to delivery, we focus on efficiency and quality at every step.

Design Upload

Upload your CAD file and technical drawings directly to our platform. Our system automatically analyzes design features for manufacturability.

Material Selection

Choose from our range of mild steel grades or receive expert recommendations based on your application requirements. We'll help select the optimal material for your specific needs.

DFM Analysis

Our manufacturing engineers review your design and provide feedback for optimizing manufacturability, cost-efficiency, and performance while maintaining design integrity.

CNC Programming

Our programmers create optimized toolpaths and process plans to ensure efficient machining of your mild steel parts, selecting appropriate cutting parameters for the specific steel grade.

Production & Quality Control

Parts are machined on our advanced CNC equipment with comprehensive in-process quality checks. Each component undergoes inspection to verify dimensions, tolerances, and surface finish quality.

Surface Finishing

If required, parts receive specified surface treatments for corrosion protection, improved appearance, or enhanced performance characteristics.

Delivery

Completed parts are carefully packaged and shipped. We offer standard and expedited shipping options, with typical lead times of less than 10 days.

CNC Machining Specifications

Price

Highly competitive pricing, especially for moderate to large volume orders

Lead Time

Typically < 10 days (expedited options available)

Wall Thickness

Minimum 0.75 mm

Tolerances

±0.125mm (±0.005″) standard, tighter tolerances available

Max Part Size

200 x 80 x 100 cm

Weight Capacity

Up to 500 kg for large components

Common Applications

Mild steel CNC machined parts are ideal for a wide range of applications across multiple industries. Here are some common uses for our mild steel components:

Automotive

- Engine components

- Chassis parts

- Transmission components

- Mounting brackets

Industrial

- Machine bases

- Fixtures and tooling

- Conveyor components

- Equipment housings

Construction

- Structural connectors

- Equipment fittings

- Hardware components

- Support brackets

Agriculture

- Equipment parts

- Implement components

- Tractor attachments

- Processing machinery

Energy

- Power generation components

- Mounting frames

- Equipment housings

- Infrastructure parts

Prototyping

- Functional prototypes

- Test fixtures

- Concept validations

- Pre-production models

Frequently Asked Questions

How much does CNC mild steel machining cost?

The cost of CNC machining mild steel depends on several factors including the complexity of the part, the specific grade of mild steel, quantity, tolerances, and any required surface finishes. Mild steel generally offers excellent value compared to other metals.

BZ Metal Products uses advanced algorithms to calculate precise costs based on your CAD file, considering material usage, machine time, and finishing operations. Simply upload your design to receive an instant quote for your mild steel parts.

What is the difference between various mild steel grades?

The main differences between mild steel grades relate to their carbon content, alloying elements, and processing methods, which affect their mechanical properties:

- 1018: General-purpose with good machinability and weldability (0.14-0.20% carbon)

- 1045: Medium carbon content (0.43-0.50%) offering higher strength but slightly less weldability

- A36: Common structural steel with excellent weldability (0.25-0.29% carbon)

- S355J2: Higher tensile strength steel with good toughness at low temperatures

- S235JR: Low carbon structural steel with excellent plasticity and weldability

Our engineers can help you select the optimal grade for your specific application requirements.

What are the advantages of using mild steel for CNC machined parts?

Mild steel offers numerous advantages for CNC machined components:

- Cost-effectiveness compared to other metals and alloys

- Excellent machinability, allowing for efficient processing

- Good weldability for assembly operations

- Reasonable strength-to-weight ratio

- Ability to be case hardened for improved surface properties

- Readily available in various forms and sizes

- Accepts a wide range of protective coatings and finishes

- Versatility for numerous applications across industries

These advantages make mild steel an excellent choice for many mechanical components, structural parts, and general-purpose machine elements.

What surface finishes are available for mild steel parts?

BZ Metal Products offers various surface finishing options for mild steel CNC machined parts:

- As-machined: Standard finish directly from the CNC machine

- Bead blasting: Uniform matte finish for improved appearance

- Black oxide: Thin black coating providing mild corrosion resistance

- Zinc plating: Excellent corrosion protection with silver-blue appearance

- Powder coating: Durable colored finish available in multiple colors

- Painting: Decorative finish with good corrosion protection

- Brushed finish: Linear grain pattern for aesthetic appeal

- Polishing: Bright reflective surface in various grades

Since mild steel is susceptible to corrosion, we typically recommend applying a protective finish for components that will be exposed to moisture or corrosive environments.

What are the design considerations for CNC machining mild steel?

When designing parts for CNC machining in mild steel, consider these important factors:

- Wall thickness: Maintain minimum wall thickness of 0.75mm to prevent warping

- Internal corners: Design with a radius rather than sharp corners to reduce stress concentration

- Deep pockets: Maintain reasonable depth-to-width ratios (typically less than 4:1)

- Thread depth: For tapped holes, maintain appropriate thread engagement (typically 1.5× diameter)

- Tolerance requirements: Specify critical dimensions while allowing looser tolerances where possible

- Surface finish: Consider specifying critical surface finish requirements

- Heat treatment: Account for any post-machining heat treatment that may affect dimensions

Our engineering team can provide a Design for Manufacturing (DFM) review of your design to identify potential issues and recommend improvements.

Get Your Parts Into Production Today

Ready to bring your mild steel parts to life? BZ Metal Products offers high-quality CNC machining services with competitive pricing and fast turnaround times. Our team of experts is ready to help you select the optimal mild steel grade and manufacturing process for your specific requirements.