Custom Laser Cutting Service

High-quality laser cut parts with fast turnaround times. Precision cutting for metal, plastic, acrylic, and wood. Free shipping on all US orders.

Get an Instant Quote See How It WorksCustom Laser Cutting Service

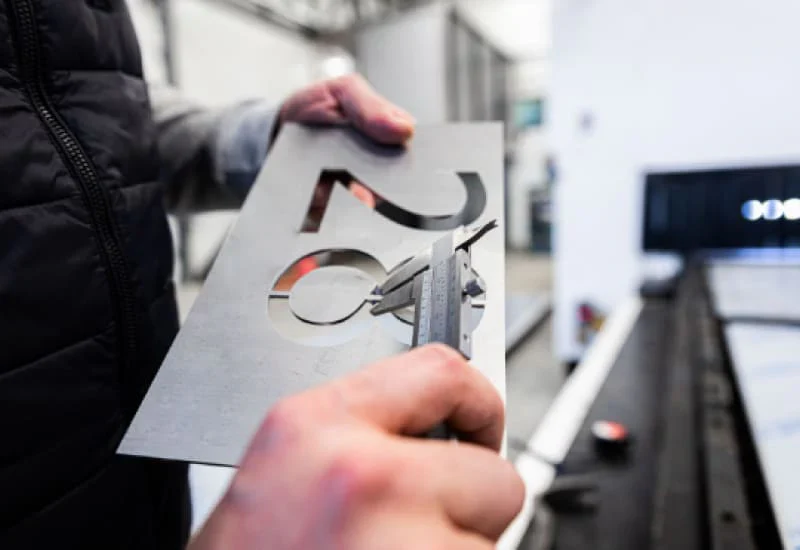

BZ Metal Products offers a premium online custom laser cutting service for metal, plastic, rubber, foam, and wood. Our laser cutting service provides a cost-effective and on-demand solution for your manufacturing needs. We support a wide variety of materials, including many different types of metal, plastic (including acrylic), rubber, foam, and wood.

Whether you need single prototype production, low-volume production, batch production, or high-volume production runs, we have the expertise and equipment to meet your requirements with precision and efficiency.

You can get an instant quote by uploading your 3D CAD file (supported formats include: STEP, STP, SLDPRT, DXF, IPT, PRT, or SAT files) through our online quoting system.

Metal Laser Cutting Service

BZ Metal Products offers high quality metal laser cutting services. Our state-of-the-art equipment can handle a variety of metal materials, including Steel, Stainless Steel, Tool Steel, Spring Steel, Aluminum, Brass, Bronze, Copper, and Titanium.

Learn more about metal cuttingMaterials We Support

BZ Metal Products offers laser cutting services for a wide range of materials. Below is a selection of commonly used materials. Please contact us if you don't see your required material listed.

Steel & Stainless Steel

- Stainless Steel 304

- Stainless Steel 316

- Steel A36

- Hot Rolled Steel 1045

- Steel 1018

- Stainless Steel 17-4 PH

- Tool Steel D2

- Corten A588 Steel

Aluminum

- Aluminum 6061 T6

- Aluminum 5052 H32

- Aluminum 2024-T3

- Aluminum 7075 T6

- Aluminum MIC6

- Pre-Anodized 6061-T6

Other Metals

- Brass 260

- Copper 110

- Bronze 220 H02

- Titanium (Grade 2)

- Titanium 6Al-4V

- Nickel 200

Plastics & Acrylics

- Acrylic, Clear

- Acrylic, Colored

- ABS, Black & White

- Polycarbonate, Clear

- HDPE, White

- Nylon 6/6

Applications of Laser Cutting

Blank Preparation

Our laser cutters can cut many materials with high precision, making it perfect for preparing flat patterns or material blanks for further processing.

Rapid Prototyping

The range of materials available, low cost per unit, and speed of production makes laser cutting a great option for prototyping your designs.

End-Use Production

Large format cutting, vast material options, and high throughput have made laser cutting a favorable technology for end-use parts.

Advantages of Laser Cutting

Durability

Laser cutting produces highly durable parts well-suited for both functional prototypes and end-use production, maintaining material integrity throughout the process.

Scalability

All sheet metal parts are built on-demand with lower setup costs compared to other manufacturing processes. Order as little as a single prototype up to 10,000 production parts.

Material Selection

Choose from a variety of materials across a wide range of strength, conductivity, weight, and corrosion resistance to meet your specific project requirements.

Rapid Turnaround

Combining the latest cutting, bending, and punching with automated technologies, BZ Metal Products provides instant quotes with parts that often ship the same week.

| Description | General Tolerance |

|---|---|

| General Tolerances | For full details on tolerances offered by BZ Metal Products' sheet cutting service, including edge to edge tolerance and taper, please consult our manufacturing standards. |

| Thickness Dimension | Thickness tolerances are determined by the material blank. |

| Minimum Recommended Part Size | 1.000" |

| Minimum Feature Size | 2X material thickness with a minimum of 0.062" |

| Kerf (slit size) | Approximately 0.020" |

| Edge Condition | Laser cut parts will have a vertical striation on the cut face. |

This table contains general information concerning BZ Metal Products' laser cutting services. Learn more about our official sheet cutting manufacturing standards.

Design Guide: Laser and Sheet Cutting

We've compiled our best tips into this comprehensive guide to help you understand laser and sheet cutting processes. Learn how to prepare your files, important design considerations for optimizing your parts for manufacturing.

Download Design GuideAn Overview of Laser Cutting

The Basics Of Laser Cutting

Laser cutting directs a high-powered laser through optics to cut materials for industrial applications. It provides both more precision and less energy consumption than plasma cutting but has an upper threshold on the thickness of the material being cut.

A laser cutting machine is a type of CNC machine that uses a thin, high-powered focused laser beam to cut materials. While commonly used for quality welding and to cut industrial sheet metal, laser cutters can also be used for other materials such as plastic, rubber, glass, wood, and aluminum.

The Laser Cutting Process

Laser cutters use focusing optics to direct electrical energy into a high-density light beam, and CNC technology to manage either the workpiece or the laser beam. The material processed by the laser cutter is then melted, burned, vaporized, or blown away by a jet of oxygen or nitrogen.

Advantages of Laser Cutting Services

The laser cutting process offers several advantages over traditional mechanical cutting or CNC machining processes, including quicker production, decreased contamination of the workpiece, and reduced chance of warping. A laser cutter produces clean laser cut parts and has a small chance of operator error, making them excellent for fast prototyping.

Types Of Laser Cutters Available

CO2 Laser Cutting Machines

The most common laser cutter type because of their relatively high energy efficiency and high power output ratio. Best suited for cutting, boring, and engraving services.

Advantages:

- High energy efficiency

- Excellent for cutting non-metals

- Lower operational costs

- Wide range of applications

Limitations:

- Less effective on reflective metals

- Limited cutting thickness for metals

Nd Laser Cutting Machines

Nd lasers have high energy output and are primarily used for boring and welding applications where high power is required.

Advantages:

- High energy output

- Effective for specialized boring

- Good for welding applications

Limitations:

- Low repetition efficiency

- More maintenance required

- Less versatile than other types

Nd:YAG Laser Cutting Machines

Nd:YAG Lasers are high-powered lasers suitable for cutting thick materials. They can be used for boring, welding, and engraving with excellent precision.

Advantages:

- Very high power capabilities

- Excellent for thick materials

- Precise for intricate cutting

- Versatile applications

Limitations:

- More expensive to operate

- Higher energy consumption

- Complex maintenance requirements

Why Choose BZ Metal Products?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order to meet your exact specifications.

Easy to Use

Get your laser cut parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping. We handle everything for you.

Quality Assured

We maintain ISO 9001:2015 certification and rigorous quality control processes. Only the top shops that apply to become suppliers make it through our qualification process.

Ready to Start Your Laser Cutting Project?

Contact us now for a free quote and professional advice