Online Sheet Metal Fabrication Service

Your online sheet metal cutting and bending service. Upload your parts, get a free instant quote and go into production in less than 5 minutes.

Our Sheet Metal Fabrication Capabilities

Our network of manufacturing partners gives you easy access to sheet metal fabrication capabilities to serve all your manufacturing needs.

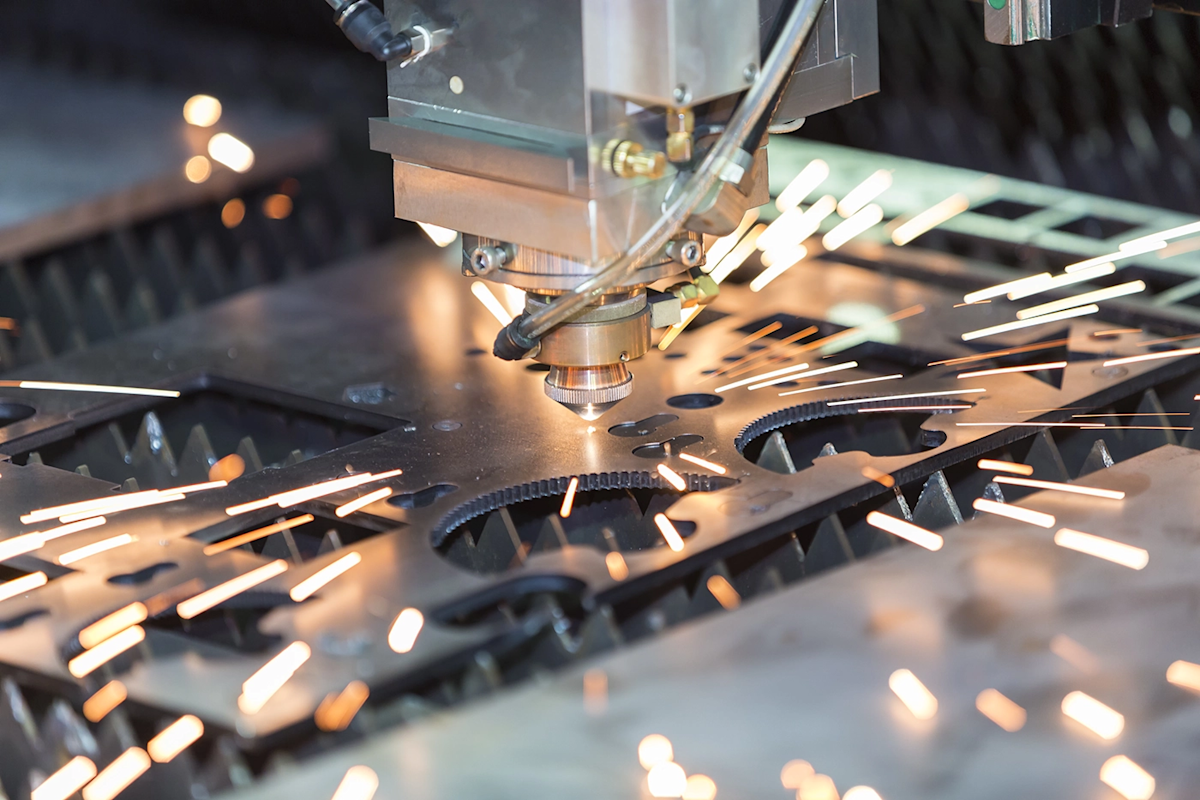

Laser Cutting

This manufacturing process uses a high-power laser beam to cut a material sheet.

- Allowable sheet thickness: 1-6mm (depending on material)

Bending

This manufacturing process uses dies to produce a U-shape, V-shape or channel shape along a straight axis in ductile materials.

- Allowable sheet thickness: 1-6mm (depending on material)

Sheet Metal Fabrication Materials

Here is a list of our standard available metals for sheet metal fabrication. If you require a custom material, please contact us.

| Aluminum | 5052, 5754 |

|---|---|

| Stainless steel | 304, 316L |

| Mild steel | 1018 |

| Copper | C110 |

Tolerances for Sheet Metal Fabrication Service

The table below summarizes the standard tolerances of the parts produced by our certified manufacturing partners.

| Feature | Tolerance |

|---|---|

| Cutting feature | ± 0.2mm |

| Bend angle | ± 1.0° |

| Bend to edge | ± 0.254mm |

Available Surface Finishes for Sheet Metal

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

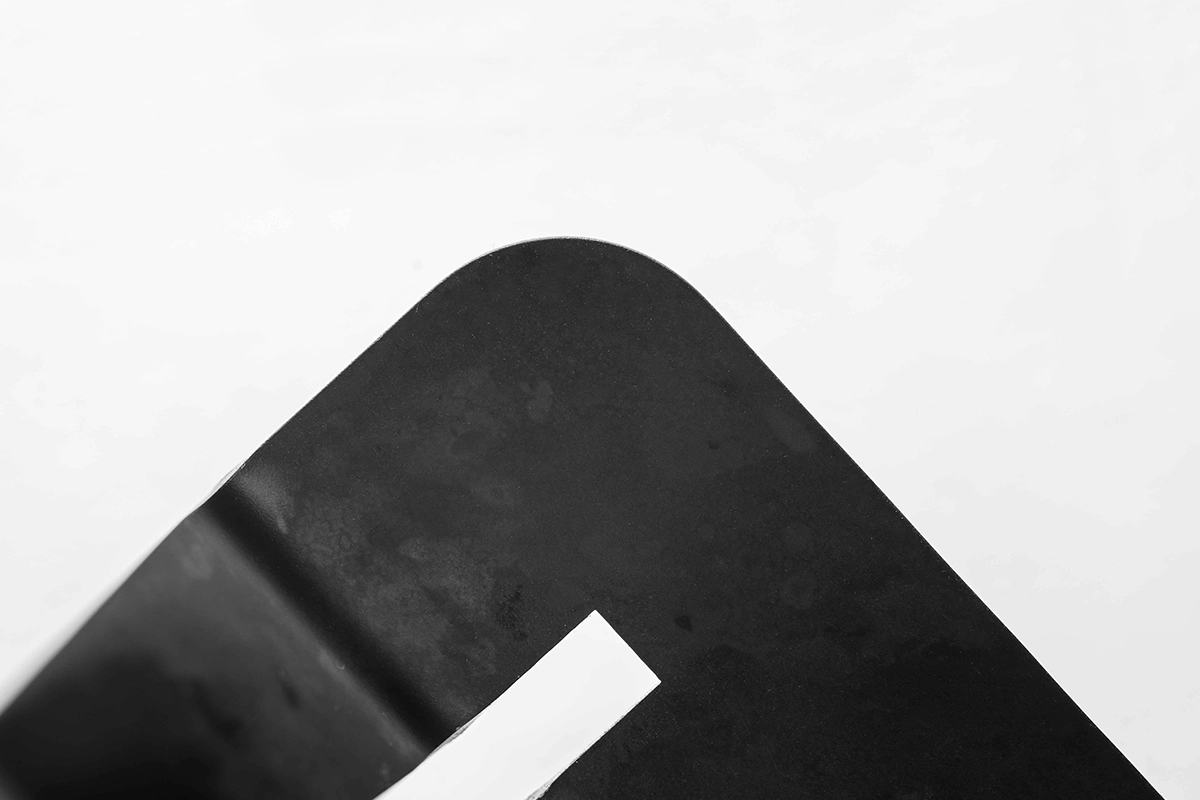

Standard

This is our standard finish. Parts are delivered as cut and bent, no additional treatment applied. Sharp edges are broken and deburred for safe handling.

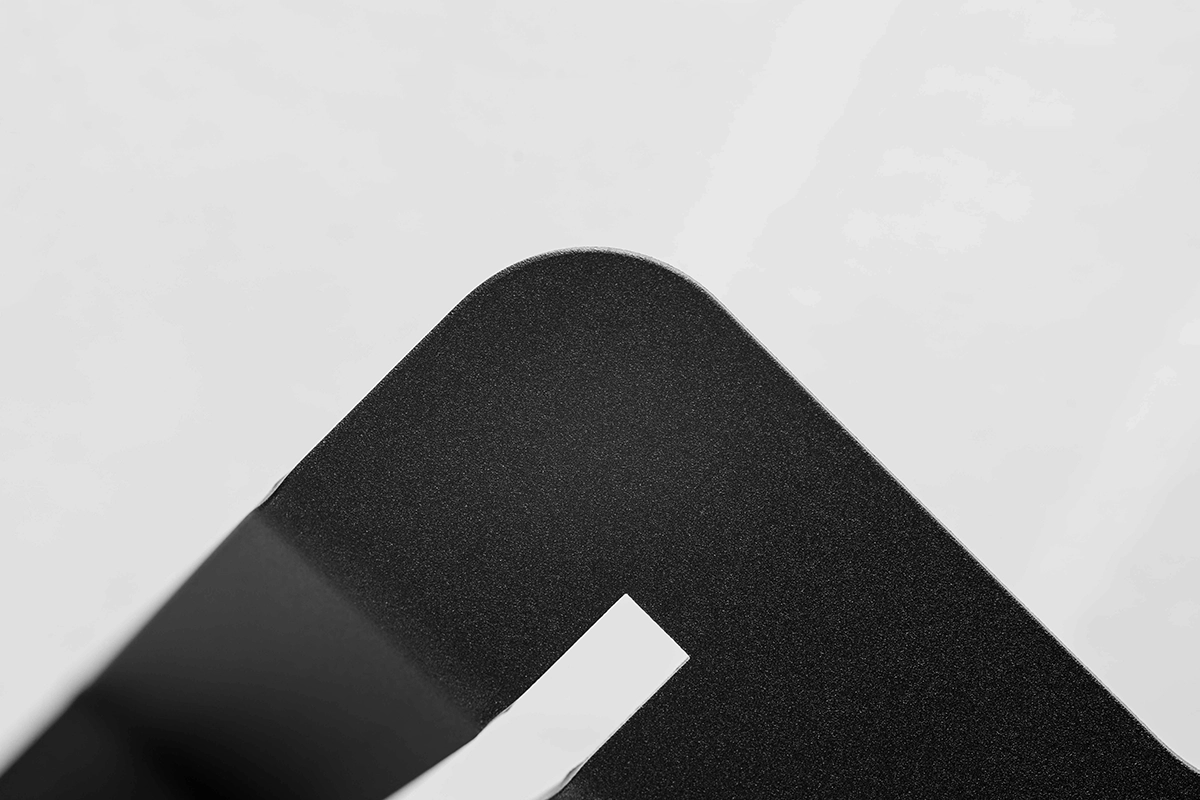

Bead Blasted

Parts are bead blasted with glass beads which results in a grainy texture. Sharp edges are broken and deburred for safe handling.

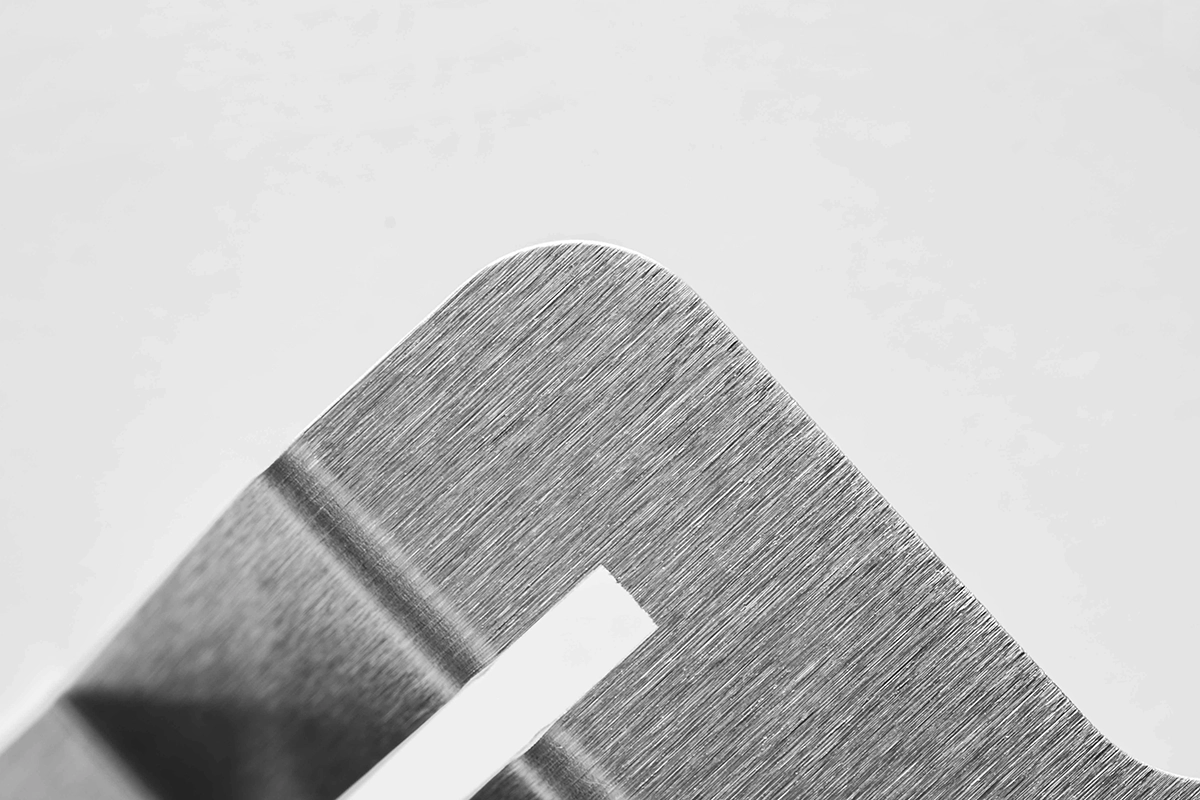

Brushed

Parts are manually brushed with grit #180 after cutting and bending. Sharp edges are broken and deburred for safe handling. Ideal to reduce the surface roughness of a part.

Brushed + Anodized Type II

Parts are dipped in an anodizing bath (type II) after manual brushing. Ideal for increasing the corrosion resistance of the part. Sharp edges are broken and deburred for safe handling.

Bead Blasted + Anodized Type II

Parts are dipped in an anodizing bath (type II) after bead blasting. Ideal for increasing the corrosion resistance of the part. Sharp edges are broken and deburred for safe handling.

Anodized Type III (Hardcoat)

Parts dipped in an anodizing (type III) bath directly after fabrication. Ideal to improve corrosion and wear resistance of components. Sharp edges are broken and deburred for safe handling.

Powder Coated

Powder coating layer is applied directly after fabrication. Sharp edges are broken and deburred for safe handling.

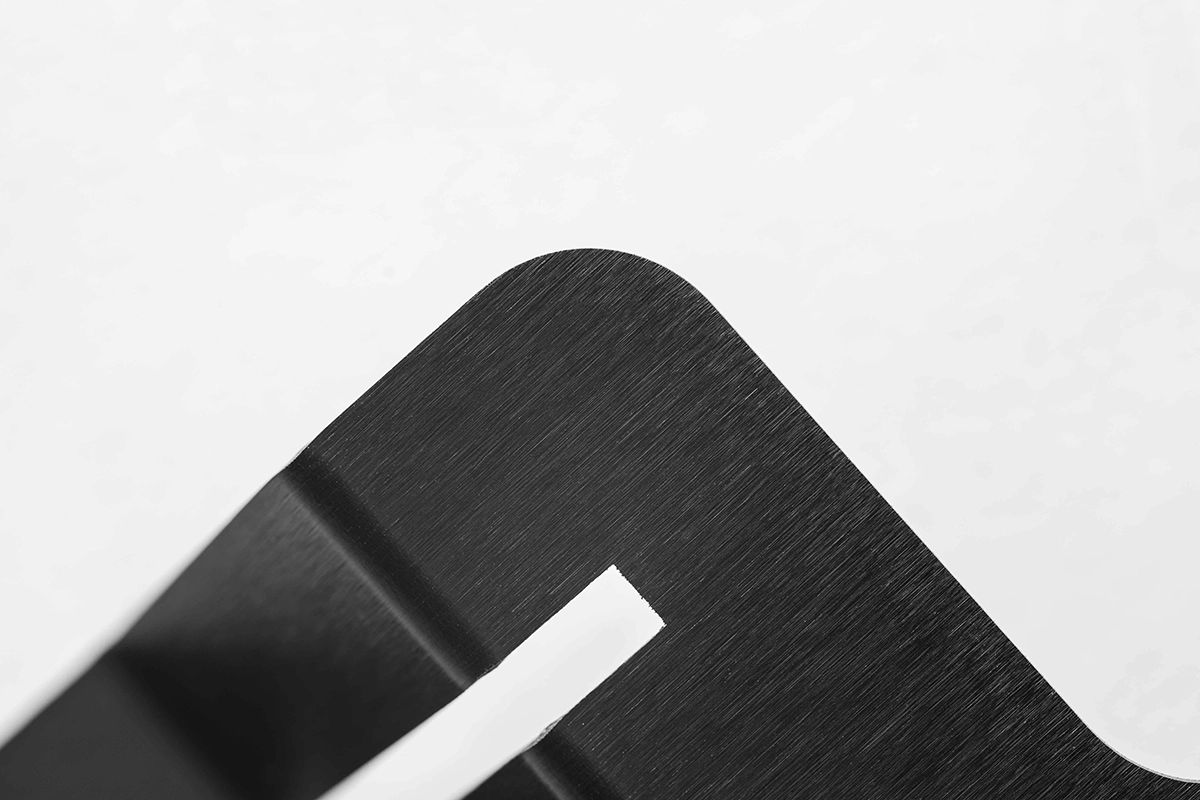

Black Oxide

Parts are dipped in a black oxide bath after fabrication. Ideal to improve corrosion resistance and minimize light reflection in steel components. Sharp edges are broken and deburred for safe handling.

Our Ordering Process

A simple six-step process from design to delivery of your sheet metal parts.

Upload CAD File

Securely upload your part design to our online quote builder

Confirm Specs

Configure your part specifications and select a lead time that suits your schedule

Receive Instant Quote

Upload your CAD to our online quoting platform

Manufacturing

We select the best manufacturer for your order, and production begins immediately

Quality Control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Your parts are delivered on time to your specified location

More Resources for Sheet Metal Fabrication

Learn more about how sheet metal fabrication works and how to design the best parts for this technology.

FAQ's About Sheet Metal Fabrication Service

We answer your common questions about sheet metal fabrication.

BZ Metal Products offers several types of materials for sheet metal fabrication. They include aluminum types 5052 and 5754, stainless steel types 304 and 316L, mild steel type 1018, and copper type C110. We can also source many custom materials on request.

We offer two types of sheet metal fabrication: laser cutting and bending. Laser cutting uses a high-power laser beam to cut a material sheet between 1 and 6mm thick, depending on the material. Bending uses dies to produce a u-shape, v-shape, or channel shape along a straight axis in ductile materials. It can work with metals 1-6mm thick.

We guarantee the quality of the parts we produce. The BZ Metal Products Standard, our comprehensive quality management system, ensures that your parts are fabricated to your specifications.

The typical turnaround time for sheet metal fabrication varies depending on the metal's thickness, design complexity and the number of parts you require. However, turnaround times generally start from five days.

Our sheet metal fabrication processes use advanced surface finishes to enhance part properties. These include bead blasting, brushing, anodizing (type II and III), powder coating, black oxide coating, and chromate conversion coating. These finishes improve corrosion and wear-resistance, surface texture, and appearance while maintaining conductive properties. All parts are deburred for safety to ensure quality and durability.

Put Your Parts Into Production Today

Contact us now for an instant quote and expert advice