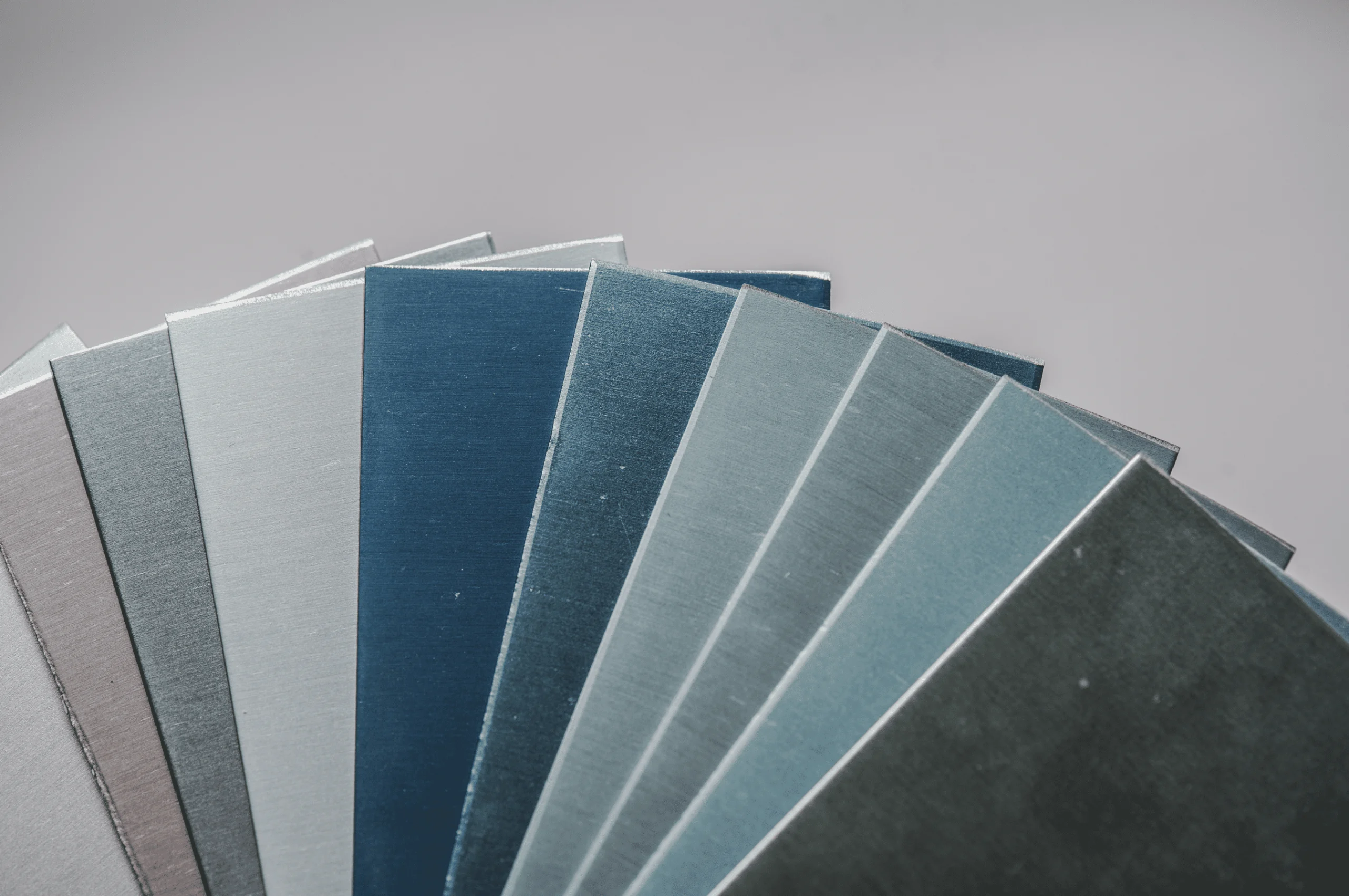

Surface Finishing Services

Enhance the aesthetics, durability, and functionality of your metal parts with BZ Metal Products' premium surface finishing services. From protective coatings to decorative finishes, we deliver exceptional quality with fast turnaround times.

Get an Instant Quote Explore Our FinishesSurface Finishing Services

BZ Metal Products offers comprehensive surface finishing services to enhance the appearance, performance, and longevity of your metal components. We provide a wide range of finishes that not only improve aesthetics but also add functional properties such as corrosion resistance, wear resistance, and electrical conductivity.

Our state-of-the-art facilities and experienced technicians ensure consistent, high-quality results that meet exact specifications and industry standards. Whether you need decorative finishes for consumer products or performance coatings for industrial applications, we have the expertise and capabilities to deliver exceptional results.

We can process components of various sizes and materials, including steel, stainless steel, aluminum, copper, brass, and more. Our efficient production workflow allows us to offer competitive pricing and fast turnaround times without compromising quality.

Finishes

We offer a wide range of surface finishing options to meet your specific aesthetic and functional requirements.

Powder Coating

A dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto grounded parts.

- Excellent durability and corrosion resistance

- Wide range of colors and textures

- Environmentally friendly process

- Cost-effective for large production runs

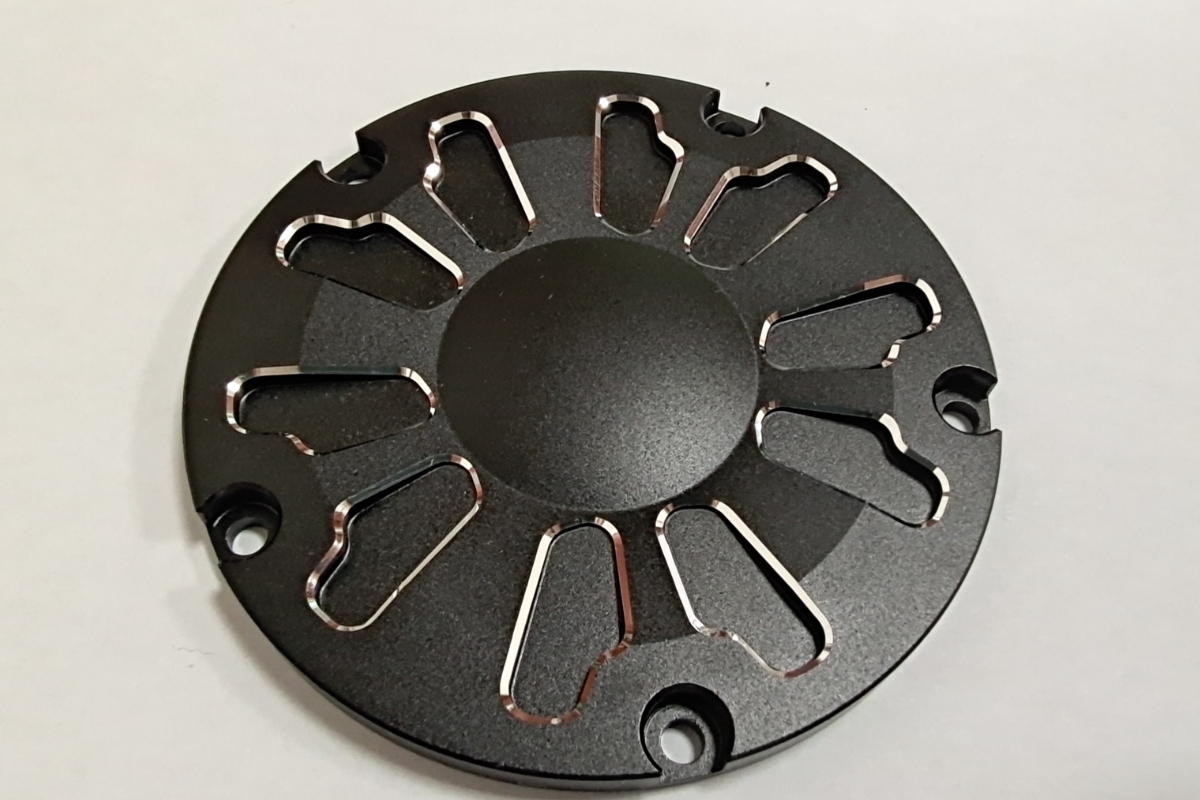

Anodizing

An electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant anodic oxide finish.

- Superior corrosion protection

- Available in various colors

- Excellent wear resistance

- Ideal for aluminum components

Plating

A process that deposits a thin layer of metal onto the surface to enhance appearance, corrosion resistance, and other properties.

- Multiple metal options available

- Enhanced surface properties

- Decorative and functional finishes

- Precise thickness control

Passivation

A chemical process that removes free iron from the surface of stainless steel and creates a protective oxide layer.

- Improves corrosion resistance

- Maintains material appearance

- Meets industry standards

- Non-toxic process

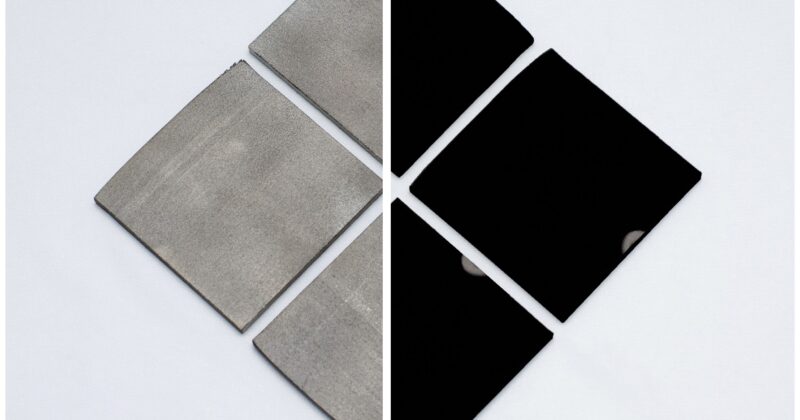

Black Oxide

A conversion coating that creates a decorative black finish while providing some corrosion resistance and anti-galling properties.

- No dimensional change

- Attractive black appearance

- Good wear resistance

- Cost-effective solution

Electropolishing

An electrochemical process that removes material from a metal surface, producing a smooth, bright finish with enhanced corrosion resistance.

- Mirror-like finish

- Improved cleanability

- Deburring capability

- Enhanced corrosion resistance

Benefits of Surface Finishing

Surface finishing does more than just improve appearance. It enhances functionality, extends product life, and adds value to your metal components.

Corrosion Resistance

Protect your metal components from rust, oxidation, and chemical damage with our specialized surface treatments. Extend the service life of your products, especially in harsh or outdoor environments, while maintaining their appearance and functionality over time.

Electrical Properties

Enhance or inhibit electrical conductivity based on your application requirements. Our surface finishes can create highly conductive surfaces for electrical components or provide insulation where needed, ensuring optimal performance in electronic applications.

Improved Appearance

Transform ordinary metal parts into visually striking components with decorative finishes. Create consistent, high-quality aesthetics across all your products, from glossy and reflective to matte and textured surfaces that align with your brand identity.

Wear Resistance

Increase the hardness and durability of metal surfaces to withstand abrasion, friction, and daily wear. Our specialized coatings create surfaces that maintain their integrity even under demanding conditions, reducing maintenance needs and extending service life.

Chemical Resistance

Apply protective layers that shield metal components from chemical exposure, acids, alkalis, and solvents. Essential for parts used in chemical processing, food production, medical devices, and other applications where chemical interaction must be minimized.

Thermal Properties

Manage heat transfer with specialized finishes that can either enhance or reduce thermal conductivity. These treatments are critical for components in heating systems, engines, electronics cooling, and applications requiring specific thermal characteristics.

Industries & Applications

Our surface finishing services cater to a wide range of industries, each with unique requirements for appearance, durability, and performance.

Aerospace

Components for aircraft, spacecraft, and defense systems require specialized finishes that provide corrosion resistance, weight reduction, and thermal protection while meeting stringent industry standards and certifications.

Explore aerospace solutions

Automotive

From decorative chrome plating to functional coatings for engine components, our finishes enhance appearance, provide wear resistance, and protect against corrosion in demanding automotive environments.

Explore automotive solutions

Medical

Medical device components require biocompatible finishes that can withstand sterilization processes, provide antimicrobial properties, and meet strict regulatory requirements for patient safety and device performance.

Explore medical solutions

Electronics

Electronic components benefit from finishes that enhance conductivity, provide EMI/RFI shielding, and protect sensitive parts from environmental factors while maintaining precise electrical characteristics.

Explore electronics solutions

Architecture

Architectural elements require durable, weather-resistant finishes that maintain their appearance for decades while withstanding UV exposure, temperature variations, and environmental pollutants.

Explore architectural solutions

Industrial

Heavy machinery and industrial equipment benefit from specialized coatings that provide extreme wear resistance, chemical protection, and safety features while operating in challenging environments.

Explore industrial solutionsOur Surface Finishing Process

BZ Metal Products follows a comprehensive process to ensure consistently high-quality surface finishes that meet your exact specifications.

Consultation

We discuss your requirements, including aesthetic preferences, functional needs, environmental considerations, and budget constraints to determine the optimal finish for your application.

Surface Preparation

Components undergo thorough cleaning, degreasing, and mechanical preparation to remove contaminants, oxides, and surface imperfections to ensure optimal finish adhesion and quality.

Application

Using state-of-the-art equipment and techniques, we apply the selected finish with precision and consistency, carefully controlling all process parameters for optimal results.

Curing/Treatment

Depending on the finish type, components undergo appropriate curing or treatment processes to develop the final properties and ensure adhesion, durability, and performance.

Quality Control

Each finished component undergoes thorough inspection and testing to verify appearance, thickness, adhesion, corrosion resistance, and other required properties before approval.

Our expert team carefully monitors each step of the process to ensure consistent quality and on-time delivery. We maintain detailed documentation and can provide certification for specialized applications requiring validation.

Design Guide for Surface Finishing

Designing parts with surface finishing in mind from the beginning can help ensure optimal results, reduce costs, and avoid potential issues during manufacturing. Our comprehensive design guide provides essential tips and best practices.

- Optimize part geometry for uniform coating coverage

- Consider material compatibility with finishing processes

- Plan for masking requirements and fixture points

- Account for dimensional changes in finishing processes

- Design with cost-effectiveness in mind

Related Services

Explore our full range of manufacturing and finishing services to enhance your metal components.

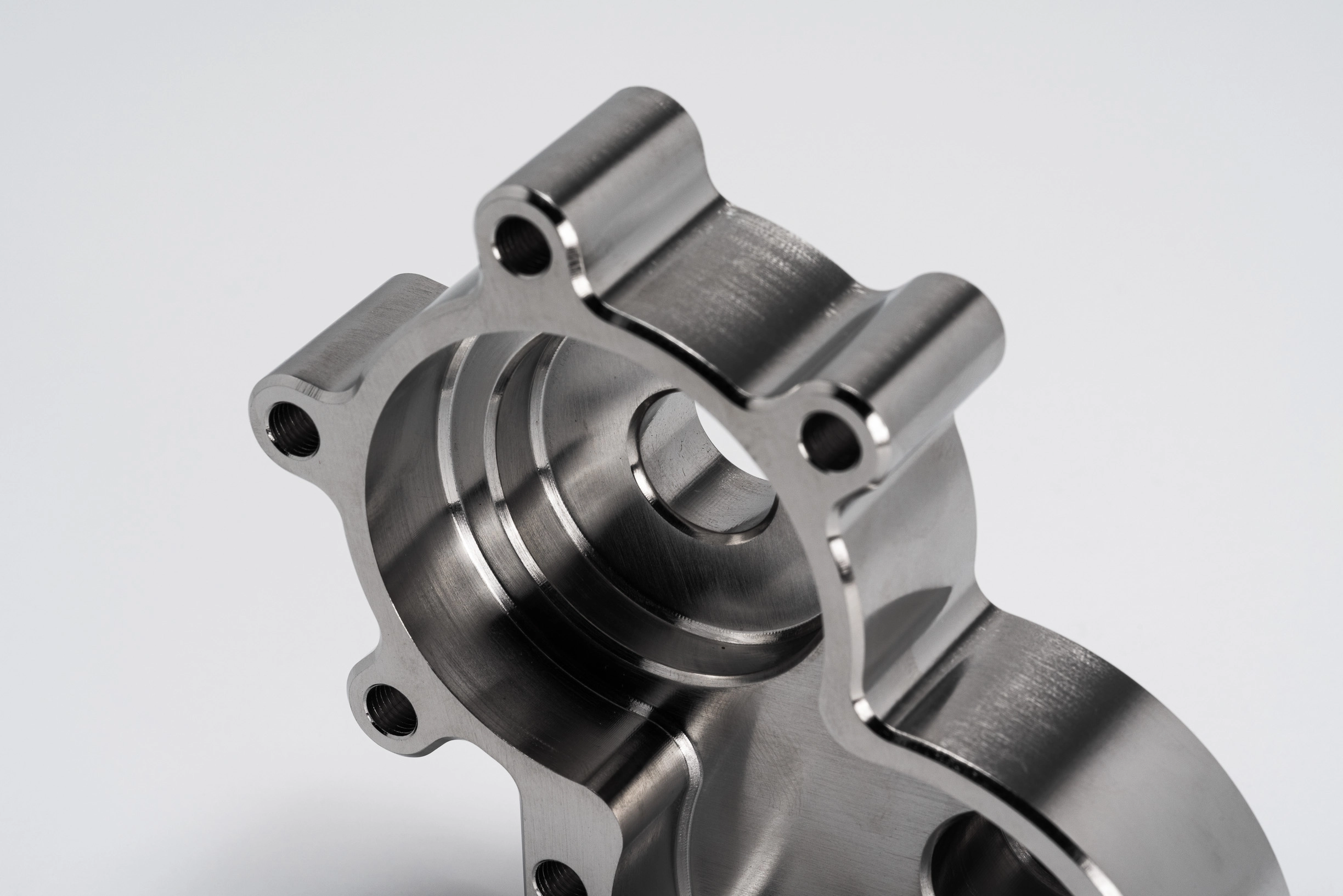

CNC Machining

Precision manufacturing of metal components using advanced CNC machines. We offer milling, turning, and multi-axis machining for complex parts with tight tolerances.

Learn more

Sheet Metal Fabrication

Complete sheet metal fabrication services including cutting, bending, welding, and assembly to create custom metal components and structures.

Learn more

Metal Stamping

High-volume production of precise metal components using progressive dies, compound dies, and transfer dies.

Learn moreFrequently Asked Questions

Find answers to common questions about our surface finishing services.

-

What surface finishes provide the best corrosion resistance?

For optimal corrosion resistance, we recommend anodizing for aluminum components, zinc or cadmium plating for steel, and passivation for stainless steel. For extreme environments, specialized coatings like epoxy-based powder coatings or certain electroless nickel finishes provide superior protection. The best choice depends on your specific material and environmental conditions.

-

How long does the surface finishing process take?

The timeline varies based on the type of finish, component complexity, quantity, and current production schedule. Simple finishes like passivation might be completed in 2-3 business days, while more complex processes like multi-layer plating or specialized powder coating might take 5-7 business days. For urgent needs, we offer expedited services at an additional cost.

-

Can you match a specific color or texture for my components?

Yes, we can match specific colors and textures for many finish types, especially powder coating and anodizing. We use color spectrophotometry technology to ensure accurate color matching against Pantone, RAL, or custom color standards. For critical applications, we recommend ordering a sample run first to verify the exact appearance before proceeding with full production.

-

What information do you need for an accurate surface finishing quote?

To provide an accurate quote, we need the component dimensions, material type, desired finish type and specifications, quantity, any masking requirements, target turnaround time, CAD files or technical drawings if available, and information about the part's end-use environment. The more details you provide, the more accurate our quote will be.

-

Do you offer any environmentally friendly surface finishing options?

Yes, we offer several environmentally friendly options, including powder coating (zero VOCs), RoHS-compliant plating processes, trivalent chromium instead of hexavalent chromium, and water-based coating systems. We continuously invest in sustainable technologies and processes to reduce environmental impact while maintaining high performance standards.

What Our Clients Say

Read what our satisfied customers have to say about our surface finishing services.

BZ Metal Products has been our go-to partner for surface finishing for over three years. Their anodizing work on our aluminum components is consistently excellent, with perfect color matching and superior wear resistance. We've reduced our rejection rate by 85% since switching to their services.

John Harrington

Production Manager, AeroTech Industries

The powder coating quality from BZ Metal Products is exceptional. We needed a specialized textured finish for our outdoor equipment that could withstand harsh weather conditions while maintaining its appearance. Their team delivered exactly what we needed and even helped us optimize our design for better coating adhesion.

Sarah Rodriguez

Design Director, OutdoorEquip Co.

We had strict regulatory requirements for our medical device components, and BZ Metal Products helped us navigate the complexities of biocompatible surface treatments. Their technical expertise, documentation, and quality control processes are impressive. We now have a reliable partner for all our surface finishing needs.

Dr. Michael Chen

R&D Manager, MedTech Innovations

Ready to Start Your CNC Machining Project?

Contact us now for a free quote and professional advice