Sustainability

Our Steps Towards More Sustainable Manufacturing

Mapping out a way forward for the industry

Understanding the Impact

Manufacturing is a complex industry with an even more complex environmental footprint. Along with part production itself, there are additional considerations, including material sourcing and shipping, waste management, and countless other factors. Every one of these steps in the manufacturing supply chain can be improved to reduce impact. We don't have a ready solution, but we believe that the first step in addressing the problem is to better understand it.

One of the ways we're taking action is by setting up a taskforce that is committed to mapping out a more sustainable future for manufacturing. Our dedicated team is working hard to identify workable practices that benefit the environment, our business and yours.

Reducing Emissions in Manufacturing

Our long-term goal is to reduce emissions as much as we can. We want to give you manufacturing solutions that come with a lighter environmental footprint and we want to be transparent about what we're doing along the way. Our first step was to implement a framework for estimating our CO2 emissions. It is a work in progress, but we wanted to share it in the hopes that it might be useful to other businesses trying to tally up their emissions.

Understanding Our Emissions

There are three different scopes of emissions used by the Greenhouse Gas (GHG) Protocol. For a company like BZ Metal Products which operates globally, our scope 1 and 2 emissions (fuels, company vehicles, electricity used in our facilities, etc.) are significant, but our scope 3 emissions (those generated during manufacturing processes) are our main focus. Because a large portion of our emissions fall into the scope 3 category, our logistics, manufacturing and raw material emissions are the priority of this framework.

We're sharing this approach so that we can be more transparent about our emissions estimates and to provide a helpful resource for others in the industry. By working together, we can drive meaningful change throughout the manufacturing sector.

Types of Emissions

Logistics emissions

Emissions from transporting and shipping parts from our facilities to customers by ground and air transport. The emissions factor follows the GLEC framework by the Smart Freight Centre.

g CO2e = d × w × EFL

d = Distance (km)

w = Weight (kg)

EFL = Logistics emissions factor (g CO2e/t-km)

Raw material emissions

Emissions generated from the production of raw materials. Emissions factors for different metals and polymers are compiled and then multiplied by the mass of the raw material.

g CO2e = (Vr × ρ) × EFm

Vr = Volume of the raw material (mm3)

ρ = Density (g/mm3)

EFm = Raw material emissions factor (g CO2e/kg)

Production emissions

Emissions from the manufacturing process. This is the energy it takes to manufacture a part from its raw material multiplied by the carbon intensity of our facilities' locations.

g CO2e = (Vr - Vp) × K × CI

Vr = Volume of raw material (mm3)

Vp = Volume of the finished part (mm3)

K = kWh of electricity per machined volume (kWh/mm3)

CI = Carbon intensity (g CO2e/kWh)

Emissions Example

To see these estimates in action, let's go through an example using a sample machined aluminum part.

Logistics Emissions

- Part volume = 29 cm3

- Aluminum density = 2.71 g/cm3

- Weight = ~79 grams

- Distance traveled = 950 km

Using the GLEC framework, weight and distance, we calculate 8.5 grams of CO2e.

Raw Material Emissions

- Volume of raw material = 165 cm3

- Weight of raw material ~450 g

- Raw material emissions factor at supplier's location ~8.5 kg CO2e

Carbon emissions for raw material production ~3.8 kg of CO2e.

Depending on the origin of the aluminum, these emissions could be as low as 2 kg.

Production Emissions

- Volume to remove = 136 cm3

- K = 0.33 kWh/cm3

- Production energy = ~45 kWh

- Carbon Intensity = 520 g CO2e/kWh

Carbon emissions from manufacturing ~23.4 kg of CO2e.

Depending on our facility's energy source, these emissions can range from 18 kg to 27 kg.

Important Consideration

Note that our framework is a simplified model that we're using to guide our CO2 emissions estimates. It allows us to monitor our impact over time and make decisions to reduce our emissions. We are working on several initiatives to enrich our data and improve our assumptions, which will result in more accurate estimates in the future.

Sustainable Manufacturing Initiatives

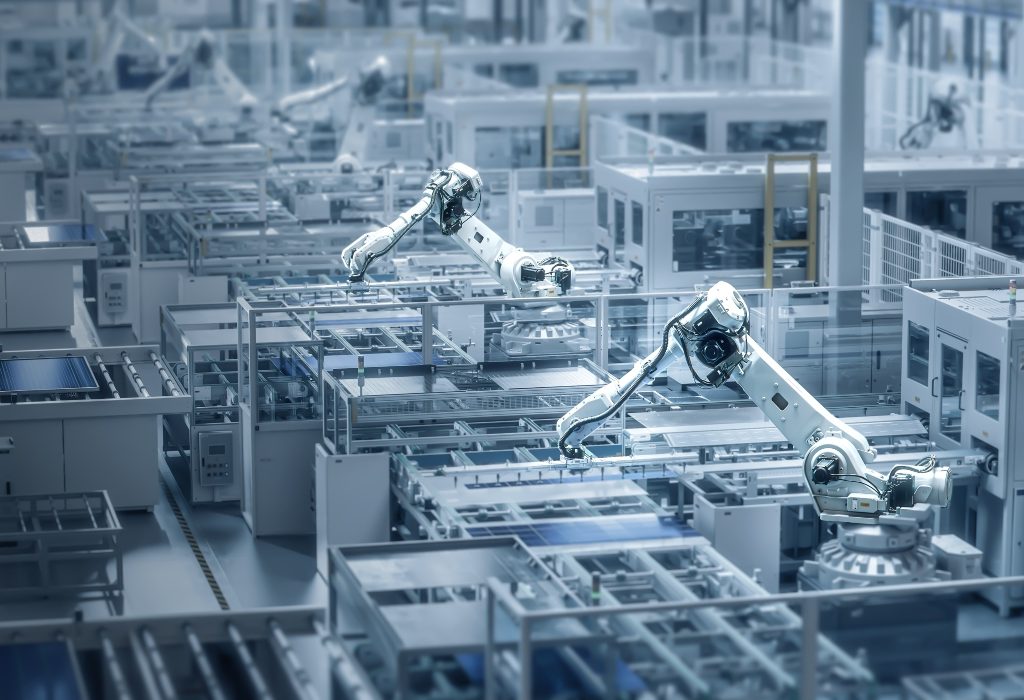

At BZ Metal Products, we're taking concrete steps to minimize our environmental footprint while maintaining the high-quality manufacturing services our customers expect. Our initiatives span across our entire operation, from materials sourcing to production processes and waste management.

Material Optimization

We employ advanced CAM software to optimize nesting and reduce material waste during cutting operations. Our design team works closely with customers to suggest material-efficient alternatives without compromising performance requirements.

- Efficient nesting patterns reduce raw material waste by up to 15%

- Design optimization to minimize material usage while maintaining strength requirements

- Material selection guidance for lower environmental impact options

Energy Efficiency

Our facilities are transitioning to more energy-efficient equipment and processes, with a focus on reducing overall energy consumption and increasing the use of renewable energy sources for our operations.

- LED lighting and smart controls throughout our manufacturing facilities

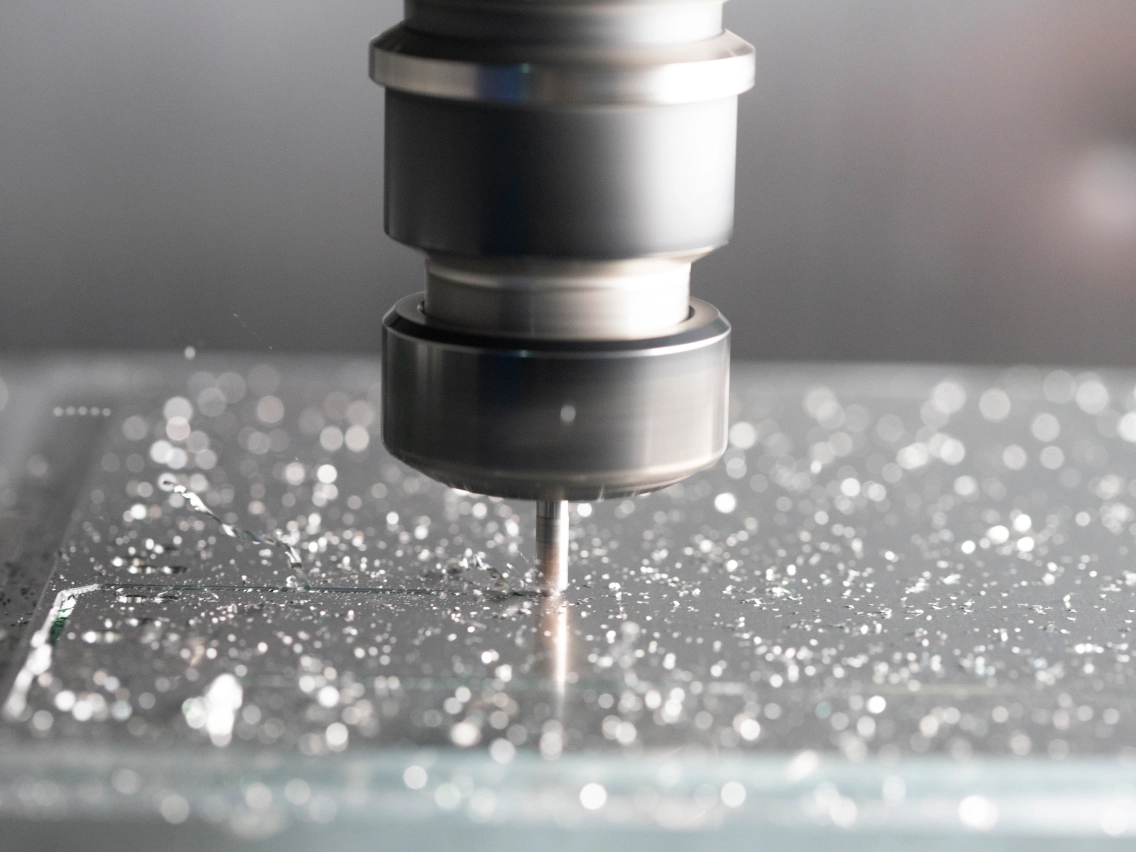

- Energy-efficient CNC machines with optimized power management

- Implementation of renewable energy sources at select facilities

- Regular energy audits and consumption monitoring

Waste Reduction & Recycling

We've implemented comprehensive waste management protocols to ensure that production waste is minimized, sorted properly, and recycled whenever possible. Metal scrap is collected and sent to certified recycling partners to reenter the supply chain.

- Systematic metal chip and scrap collection system for recycling

- Certified recycling partners for various waste categories

- Coolant filtration and recycling systems to reduce liquid waste

- Paperless documentation wherever possible

Practical Sustainability in Manufacturing

Implementing sustainable practices in manufacturing requires balancing environmental considerations with production requirements. At BZ Metal Products, we focus on practical approaches that make a meaningful difference while maintaining the quality, timeline, and cost effectiveness our customers expect.

Our Approach Includes:

- Optimizing Tool Life: Proper tool management and optimization of cutting parameters not only improves part quality but reduces the environmental impact of tooling consumption and energy use.

- Digital Prototyping: We utilize advanced simulation software to reduce physical prototyping needs, saving materials and energy while accelerating development cycles.

- Local Sourcing: When possible, we source materials locally to reduce transportation emissions and support regional economies.

- Preventive Maintenance: Regular maintenance of our equipment ensures optimal energy efficiency and extends machine lifespans, reducing manufacturing resource consumption.

Our Environmental Certifications

We're committed to meeting industry standards for environmental management and sustainable operations. Our facilities maintain key certifications that reflect our ongoing commitment to environmental responsibility.

ISO 9001:2015

Our environmental management system is certified to ISO 9001:2015, demonstrating our commitment to minimizing environmental impact and continually improving our environmental performance.

"Sustainability isn't just about meeting regulations—it's about proactively finding better ways to manufacture that reduce environmental impact while creating superior products. At BZ Metal Products, we believe that sustainable manufacturing is not only responsible—it's good business."

Director of Sustainability, BZ Metal Products

Our Sustainability Roadmap

We are committed to continuous improvement in our sustainability practices. Our roadmap outlines key milestones we plan to achieve in the coming years.

Foundation Building

- Complete comprehensive carbon emissions assessment across all facilities

- Implement energy efficiency improvements in our largest manufacturing centers

- Launch employee sustainability training program

- Enhance material waste recycling processes

Scaling Sustainable Operations

- Achieve 30% reduction in carbon emissions across all operations

- Transition to 50% renewable energy at key manufacturing facilities

- Implement closed-loop material recovery system for metal waste

- Launch sustainable supplier program with key partners

Transformative Change

- Achieve carbon neutrality across all global operations

- Power 75% of operations with renewable energy

- Implement full circular economy principles for materials

- Lead industry collaboration for sustainable manufacturing standards

Frequently Asked Questions

How do your sustainability efforts impact part costs?

While some sustainability initiatives require initial investment, many of our efficiency improvements actually reduce operational costs over time. We work to balance environmental responsibility with competitive pricing, and in many cases, practices like reducing material waste directly lower costs. When specific sustainable options might affect pricing, we provide transparent information to help customers make informed decisions.

Do you provide sustainability data for the parts I order?

Yes, we can provide carbon footprint estimates for your manufactured parts upon request. Our emissions calculation framework allows us to estimate the CO2 emissions associated with the raw materials, manufacturing processes, and shipping of your parts. This information can be valuable for companies tracking their supply chain emissions as part of their own sustainability reporting.

How can I make my part designs more sustainable?

Our engineering team can provide design recommendations to improve the sustainability of your parts, including material selection guidance, design optimizations to reduce material usage while maintaining performance requirements, and process selection to minimize environmental impact. We offer this as a complementary service for qualifying projects and encourage customers to discuss sustainability goals during the initial design phase.

Do you use recycled materials in your manufacturing?

Yes, when appropriate for the application and when it meets all required specifications. Many of our metal suppliers provide materials with recycled content, particularly aluminum and steel. We can work with you to specify materials with higher recycled content when desired. However, for certain critical applications or specific material grades, recycled content may be limited to ensure the necessary mechanical properties and quality standards.

Join Us on Our Sustainability Journey

We believe that meaningful environmental progress requires collaboration across the entire manufacturing ecosystem. We invite our customers, suppliers, and industry partners to join us in developing and implementing more sustainable manufacturing practices.

Ways to Participate:

- Share your sustainability goals with our team during project planning

- Consider material and process alternatives with lower environmental impact

- Participate in our sustainable design feedback program

- Join our quarterly sustainability innovation forums

Together, we can drive innovation that benefits both business and the environment.

Interested in Sustainable Manufacturing?

Contact our team to discuss how our sustainable manufacturing practices can support your project goals and environmental initiatives.