Learn to design better parts for 3D printing, CNC machining, injection molding and sheet metal fabrication. Compare materials and post-processing methods. Keep leveling up your digital manufacturing expertise. Search

The Knowledge Base

Learn to design better parts for 3D printing, CNC machining, injection molding and sheet metal fabrication. Compare materials and post-processing methods. Keep leveling up your digital manufacturing expertise.

What Engineers Are Reading Now

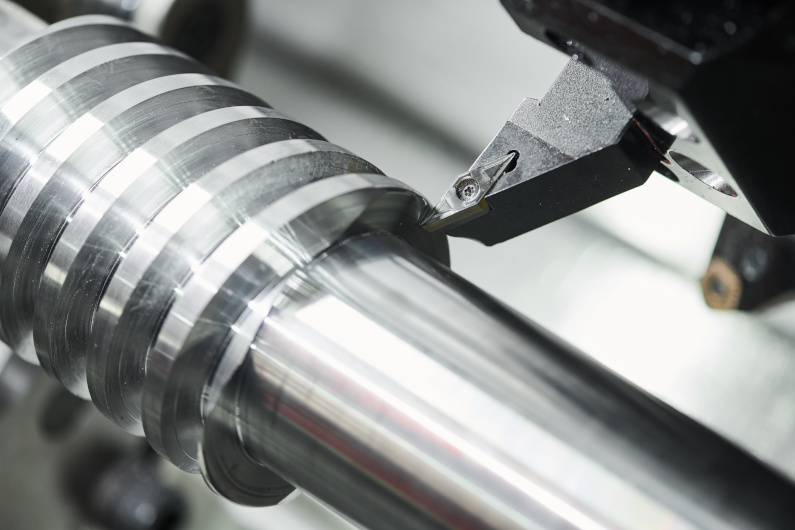

Achieving Optimal Speed in CNC Machining

When it comes to CNC machining, balancing speed and precision is crucial. This article explores cutting-edge techniques for maximizing machining efficiency without sacrificing quality, including high-speed toolpaths, optimal cutting parameters, and smart fixturing methods.

Read more

Understanding Metal Properties for Better Manufacturing Decisions

Every time you design a part for automotive, aerospace, or consumer electronics, you're making critical decisions about material properties. This comprehensive guide breaks down the essential characteristics of common metals and alloys, helping you select the optimal material for your specific application.

Read more

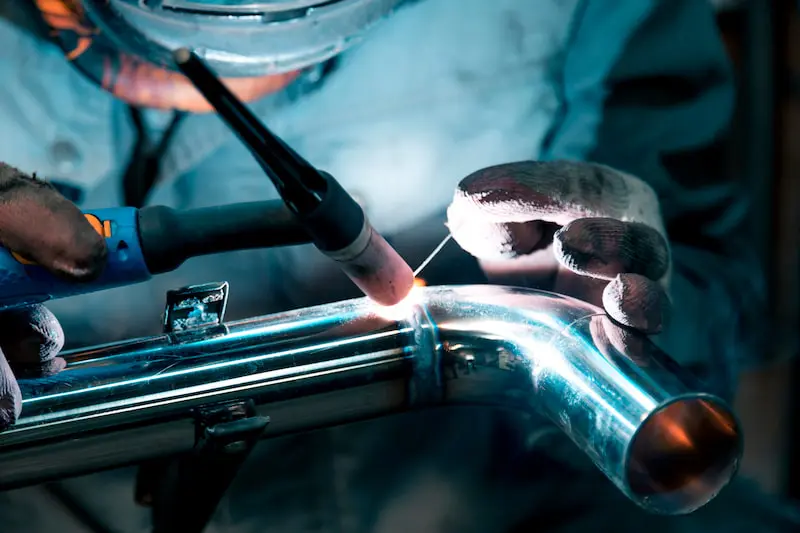

How Does TIG Welding Work?

TIG welding, or tungsten inert gas welding, is the precision craft of the welding world. It's all about clean lines and strength. Whether you're building something for aerospace or crafting sleek welds for automotive projects, TIG welding gets the job done beautifully. This article covers how it works, its benefits, and how to get the best results.

Read more

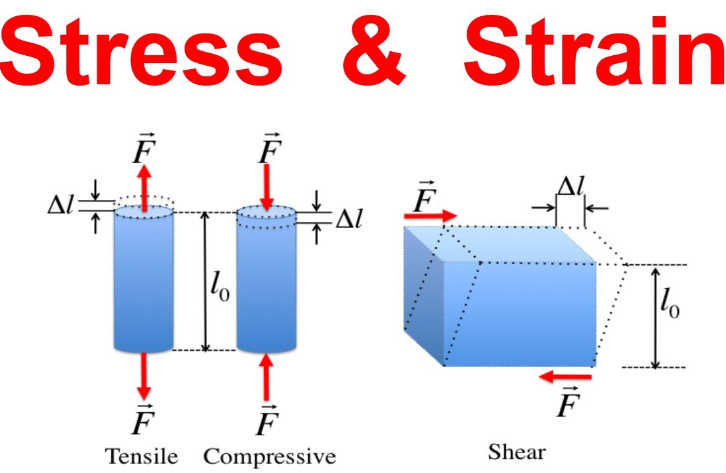

Understanding Material Stress vs. Strain

"Can you handle the pressure?" That's the question engineers have to ask of every material they consider when they are designing for manufacturability. Stress and strain are fundamentals of material science, helping engineers assess how materials hold up under different forces. Read on to find out how they are measured.

Read moreOur Manufacturing Capabilities

BZ Metal Products delivers high-quality, custom-manufactured parts using cutting-edge CNC machining and sheet metal fabrication processes. From prototypes to production runs, our services are designed to meet your exact specifications with rapid turnaround times.

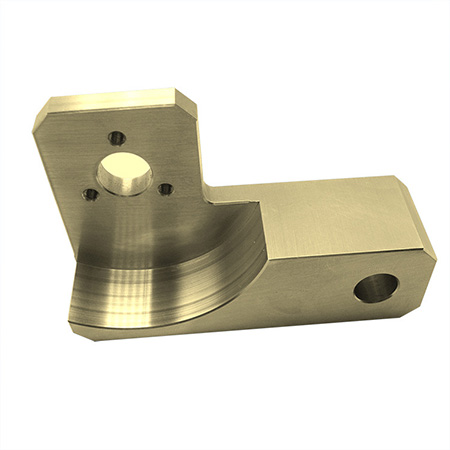

CNC Machining Services

Our state-of-the-art CNC machining capabilities transform your designs into precise metal and plastic components. With multi-axis milling and turning, we can produce complex geometries with tight tolerances.

CNC Milling

3, 4 & 5-axis precision machining

CNC Turning

Complex cylindrical part production

Surface Finishing

Anodizing, polishing, & more

Part Marking

Laser etching & engraving

Sheet Metal Fabrication Services

From prototype to production, our sheet metal fabrication services deliver high-quality, precise metal components. We work with various thicknesses and materials to create custom parts for diverse applications.

Precision Cutting

Laser, punching & waterjet

Bending

Press brake & roll forming

Welding

TIG, MIG & spot welding

Assembly

Hardware insertion & assembly

Manufacturing Materials

At BZ Metal Products, we work with a wide range of high-quality metals and plastics to meet your specific application requirements. From lightweight aluminum to durable tool steel, we'll help you select the ideal material for your project.

Aluminum

Lightweight with excellent machinability, corrosion resistance, and thermal conductivity.

Steel

Versatile with high strength, good machinability, and excellent value for many applications.

Stainless Steel

Exceptional corrosion resistance with attractive finish and good mechanical properties.

Brass

Excellent machinability with good electrical conductivity and attractive gold-like appearance.

Copper

Superior electrical and thermal conductivity with excellent corrosion resistance.

Titanium

Exceptional strength-to-weight ratio with outstanding corrosion resistance.

ABS

Good impact resistance and mechanical properties with excellent machinability.

Acetal (Delrin)

Excellent dimensional stability with low friction and good wear properties.

Nylon

High strength and toughness with excellent wear resistance and low friction.

Polycarbonate

Excellent impact resistance with good transparency and dimensional stability.

Industry Applications

BZ Metal Products serves a diverse range of industries with custom manufacturing solutions. Our expertise in CNC machining and sheet metal fabrication allows us to create precision components for even the most demanding applications.

Aerospace

High-performance components machined to precise tolerances with traceability and certifications required for aerospace applications. We work with aluminum, titanium, and specialty alloys.

- Structural components

- Engine mounts and brackets

- Interior fittings

- Testing equipment

Medical

Precision medical components manufactured in compliance with strict regulatory requirements. Our clean manufacturing processes and quality controls meet medical industry standards.

- Surgical instruments

- Diagnostic equipment components

- Medical device housings

- Laboratory equipment

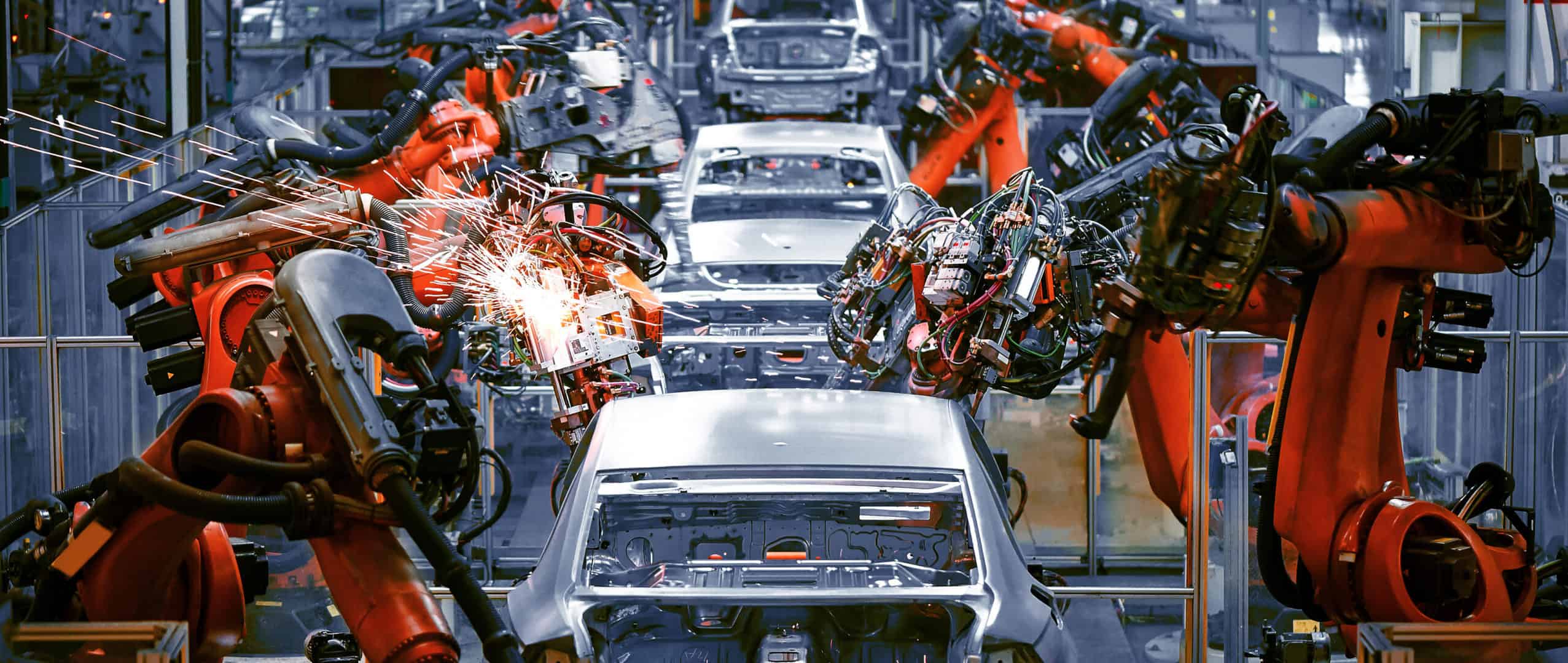

Automotive

From prototypes to production runs, we manufacture high-quality components for the automotive industry. Our expertise includes working with various metals and high-performance plastics.

- Performance parts

- Prototype components

- Production brackets and mounts

- Custom tooling

Electronics

Precise components for electronic devices, telecommunications equipment, and IT hardware. We work with materials offering excellent EMI shielding and thermal management properties.

- Enclosures and housings

- Heat sinks

- Mounting brackets

- Connector components

Industrial

Durable components for industrial machinery, automation systems, and equipment. Our manufacturing capabilities scale from one-off parts to production quantities.

- Machinery components

- Automation equipment parts

- Jigs and fixtures

- Custom tooling

Energy

Specialized components for traditional and renewable energy systems. We work with materials designed to withstand extreme environments and operating conditions.

- Solar mounting systems

- Wind turbine components

- Oil and gas equipment parts

- Power generation hardware

Frequently Asked Questions

Find answers to common questions about our manufacturing services, capabilities, materials, and processes. If you don't see your question answered below, please contact our team for assistance.

What is the typical lead time for CNC machined parts?

Our standard lead time for CNC machined parts is 5-10 business days, depending on complexity, material availability, and order quantity. For simpler parts or rush orders, we offer expedited services that can deliver parts in as little as 3 business days. During the quoting process, we'll provide you with a specific lead time estimate for your project.

What file formats do you accept for CNC machining?

We accept industry-standard 3D CAD file formats including STEP (.stp, .step), IGES (.iges, .igs), SolidWorks (.sldprt), Solid Edge (.par, .asm), AutoCAD (.dwg, .dxf), and more. For best results, we recommend using STEP or IGES formats, as they are widely compatible and preserve model integrity. If you have 2D drawings, please include them alongside your 3D models for dimensional verification.

What tolerances can you achieve with CNC machining?

Our standard tolerances for CNC machined parts are ±0.125mm (±0.005"). For more critical dimensions, we can achieve tighter tolerances of ±0.025mm (±0.001") on specific features when required. Tolerance capabilities may vary based on material, part geometry, and feature size. Please specify any critical tolerances in your design files or notes when requesting a quote.

What surface finishes are available for my parts?

We offer a wide range of surface finishes for both metal and plastic components, including:

- As Machined: Standard finish directly from CNC machining

- Bead Blasting: Uniform matte finish that hides tool marks

- Anodizing: Protective oxide layer for aluminum parts (Type II or Type III, various colors)

- Powder Coating: Durable and attractive colored finish for metals

- Polishing: Various degrees from satin to mirror finish

- Passivation: Chemical treatment for stainless steel to improve corrosion resistance

- Black Oxide: Decorative black finish for steel parts

Custom finishes may also be available upon request. Please specify your finishing requirements when ordering.

Do you provide design assistance or DFM feedback?

Yes, we offer design for manufacturing (DFM) feedback as part of our service. Our engineering team reviews every design and provides suggestions to optimize your parts for CNC machining or sheet metal fabrication. This can include recommendations for:

- Improving manufacturability

- Reducing costs

- Enhancing functionality

- Optimizing material selection

- Addressing potential issues before production

For more comprehensive design assistance, we also offer engineering consultation services where our team can work with you from concept to final design.

What quality control measures do you have in place?

We maintain strict quality control throughout our manufacturing process. Our comprehensive quality assurance program includes:

- First article inspection on all production runs

- In-process inspection during manufacturing

- Final dimensional verification using precision measuring equipment (CMMs, micrometers, calipers)

- Material certification verification

- Surface finish inspection and verification

- Documentation and traceability for all parts

For specialized requirements, we can also provide formal inspection reports, material certifications, or comply with specific quality standards as needed.

Need More Information?

Our team of manufacturing experts is ready to help you with your project. Whether you have questions about materials, processes, or need a quote, we're here to assist you every step of the way.

Additional Resources

Design Guides

Comprehensive guides for designing parts for CNC machining and sheet metal fabrication.

Download guidesCase Studies

See how we've helped other companies solve their manufacturing challenges.

View case studiesReady to Start Your Sheet Metal Project?

Contact us now for a free quote and professional advice