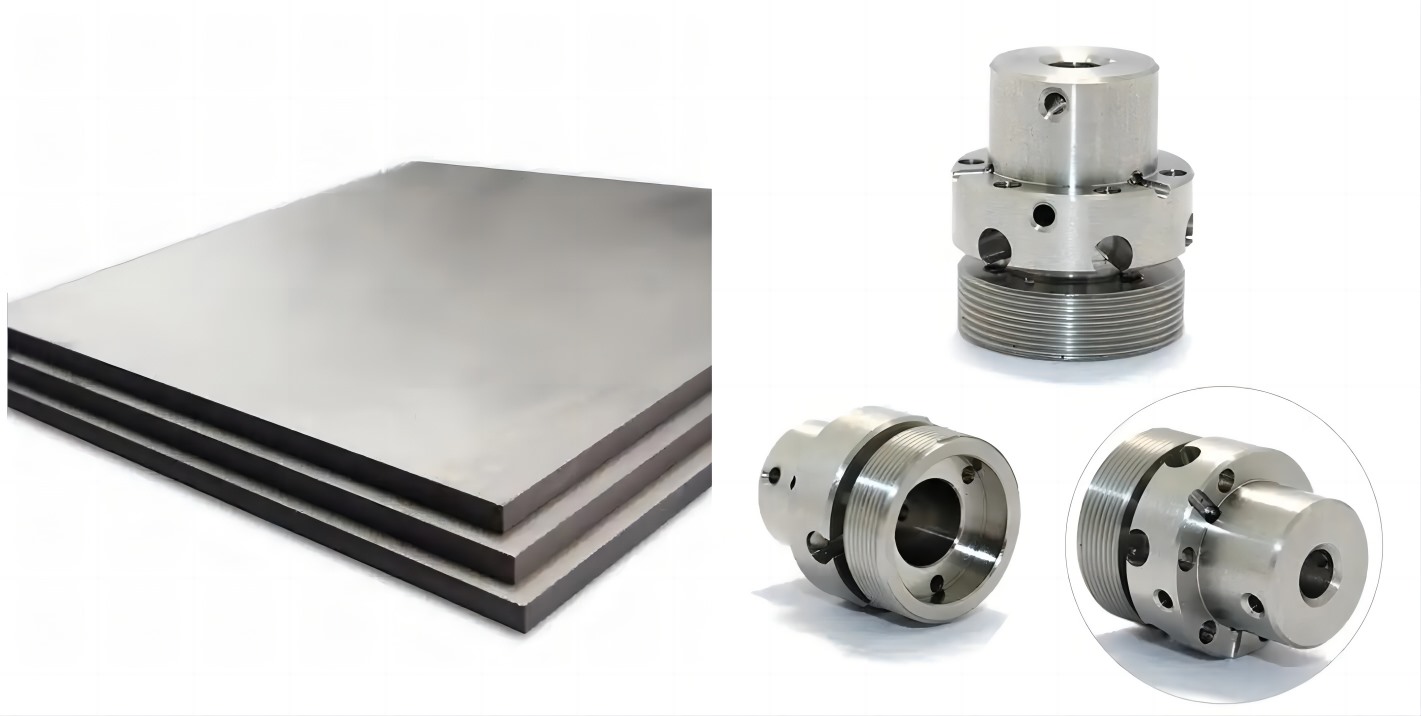

CNC Machining in Titanium

Excellent strength-to-weight ratio, used in aerospace, automotive and medical industries. Titanium is a metal with exceptional strength-to-weight ratio, low thermal expansion and high corrosion resistance that is sterilizable and biocompatible.

Order CNC Machined Titanium Parts

Custom Titanium Parts

Titanium is a lightweight, high-strength metal with exceptional corrosion resistance and biocompatibility. With its distinctive silver-gray appearance and remarkable properties, titanium delivers an impressive strength-to-weight ratio that is 40% lighter than steel while being only 5% weaker.

BZ Metal Products offers precision CNC machining services for titanium components with tight tolerances and excellent surface finishes. Our capabilities include both 3-axis and 5-axis CNC milling and turning, enabling us to create complex geometries for your most demanding applications in aerospace, medical technology, automotive, and energy industries.

Superior Strength-to-Weight

Titanium offers an exceptional strength-to-weight ratio, making it ideal for applications where weight reduction is critical without sacrificing structural integrity

Exceptional Corrosion Resistance

Natural resistance to corrosion in most environments, including seawater and harsh chemicals, due to its stable, self-healing oxide layer

Biocompatible Properties

Excellent biocompatibility makes titanium the material of choice for medical implants, surgical instruments, and other healthcare applications

CNC Machining Titanium Materials

BZ Metal Products offers high-quality titanium alloys for CNC machining. Our titanium materials provide excellent strength-to-weight ratio, corrosion resistance, and biocompatibility for your precision components in aerospace, medical, and industrial applications.

Titanium Grade 5

3.7164 | Ti6Al4V

Titanium Grade 5 (Ti6Al4V) is the most widely used titanium alloy, containing 6% aluminum and 4% vanadium. It offers an exceptional combination of strength, light weight, corrosion resistance, and high temperature performance. Ideal for aerospace components, medical implants, and high-performance automotive parts.

Titanium Grade 2

3.7035 | Commercially Pure Titanium

Titanium Grade 2 is a commercially pure titanium that provides excellent corrosion resistance, good formability, and moderate strength. It offers superior biocompatibility and is widely used in chemical processing equipment, marine applications, and medical devices where maximum corrosion resistance is required.

Additional Titanium Grades Available by Request

Titanium Grade 1

Highest purity with excellent formability and corrosion resistance

Titanium Grade 7

Enhanced corrosion resistance with palladium addition

Titanium Grade 9

Ti-3Al-2.5V alloy with good cold formability and moderate strength

Titanium Properties Overview

| Property | Titanium Grade 5 | Titanium Grade 2 | Units |

|---|---|---|---|

| Tensile Strength | 895-930 | 345-485 | MPa |

| Yield Strength (0.2% Offset) | 825-869 | 275-410 | MPa |

| Elongation | 10-15 | 20-25 | % |

| Hardness (Brinell) | 334-353 | 160-200 | HB |

| Elasticity Modulus | 113.8 | 105-110 | GPa |

| Machinability (relative to free-cutting steel) | 22 | 30 | % |

| Property | Titanium Grade 5 | Titanium Grade 2 | Units |

|---|---|---|---|

| Density | 4.43 | 4.51 | g/cm³ |

| Melting Point | 1604-1660 | 1665-1675 | °C |

| Thermal Conductivity | 6.7 | 16.4 | W/m·K |

| Electrical Resistivity | 168 | 56 | μΩ·cm |

| Coefficient of Thermal Expansion | 8.6 | 8.6 | μm/m·K |

| Specific Heat Capacity | 560 | 523 | J/kg·K |

| Element | Titanium Grade 5 | Titanium Grade 2 |

|---|---|---|

| Titanium (Ti) | Balance | Balance |

| Aluminum (Al) | 5.5-6.75% | - |

| Vanadium (V) | 3.5-4.5% | - |

| Iron (Fe) | max 0.30% | max 0.30% |

| Oxygen (O) | max 0.20% | max 0.25% |

| Carbon (C) | max 0.08% | max 0.08% |

| Nitrogen (N) | max 0.05% | max 0.03% |

| Hydrogen (H) | max 0.015% | max 0.015% |

Titanium Characteristics & Applications

Mechanical Performance

Titanium offers exceptional strength-to-weight ratio (40% lighter than steel with only 5% less strength), good fatigue properties, and crack resistance. Its high strength is maintained at elevated temperatures, making it ideal for aerospace and high-performance applications.

Corrosion Resistance

Titanium forms a stable, protective oxide layer that provides exceptional resistance to corrosion in most environments, including seawater, acids, and chlorides. This natural passivation makes titanium ideal for marine applications, chemical processing, and medical implants.

Biocompatibility

Titanium's exceptional biocompatibility and non-toxicity make it the material of choice for medical implants and surgical instruments. The material integrates well with human bone and tissue, rarely triggering allergic reactions or rejection by the body's immune system.

Machining Considerations

While titanium provides remarkable properties, it requires specialized machining techniques. Its low thermal conductivity, high chemical reactivity with cutting tools, and low elastic modulus demand optimized cutting parameters, proper tooling, and cooling strategies to achieve high-quality components.

Titanium CNC Machining Services

BZ Metal Products offers specialized CNC machining services for titanium components, from prototypes to production runs. Our expertise in working with this challenging material allows us to deliver high-quality, precision-machined titanium parts for aerospace, medical, marine, and industrial applications.

Expert Titanium Machining

Our specialized tooling and optimized machining techniques are specifically developed for titanium's unique properties. We employ proper cutting speeds, feed rates, and cooling strategies to overcome titanium's low thermal conductivity and chemical reactivity.

High Precision Components

We deliver titanium components with tolerances as tight as ±0.025mm, maintaining dimensional accuracy even for complex geometries. Our 5-axis machining centers are ideal for creating intricate medical implants and aerospace components.

Surface Finishing Options

We offer various finishing options for titanium components, including bead blasting, anodizing, passivation, and polishing. These treatments enhance appearance, corrosion resistance, and wear characteristics while maintaining tight tolerances.

Titanium Machining Process

Machining titanium requires specialized knowledge and equipment due to its unique material properties. Our systematic approach ensures high-quality components while managing titanium's challenging characteristics.

Material Selection & Verification

We select the appropriate titanium grade based on your application requirements and verify material certification to ensure authenticity and quality before machining begins.

Design Optimization

Our engineering team reviews your design for manufacturability, suggesting modifications if needed to optimize the part for titanium's specific properties and machining constraints.

Specialized Programming

We develop CAM programs specifically for titanium, using tool paths that maintain consistent chip load, minimize heat buildup, and reduce cutting forces to extend tool life and enhance part quality.

Tool Selection & Preparation

We use specialized carbide cutting tools with geometries designed specifically for titanium. Tools are prepared with proper coatings and edge preparations to withstand titanium's abrasive nature.

Precision Machining

Components are machined with heavy-duty equipment using low cutting speeds, high feed rates, and abundant cooling to control heat generation. Rigid setups minimize vibration and maintain dimensional stability.

Surface Treatments

Depending on your requirements, components may undergo various surface treatments including passivation to enhance the natural oxide layer, anodizing for color-coding and wear improvement, or mechanical finishing.

Quality Assurance

All titanium components undergo comprehensive inspection using precision measuring equipment. Critical dimensions are verified, and surface finish is assessed to ensure conformance to specifications.

Cleaning & Packaging

Finished parts undergo thorough cleaning to remove any machining residues. Components are specially packaged to protect surface finishes and prevent contamination during shipping and storage.

CNC Machining Specifications

Price

$$$$

Lead Time

< 10 days

Wall Thickness

0.75 mm

Tolerances

±0.125 mm

Max Part Size

200 x 80 x 100 cm

Surface Finish

Ra 0.8 - 3.2 μm

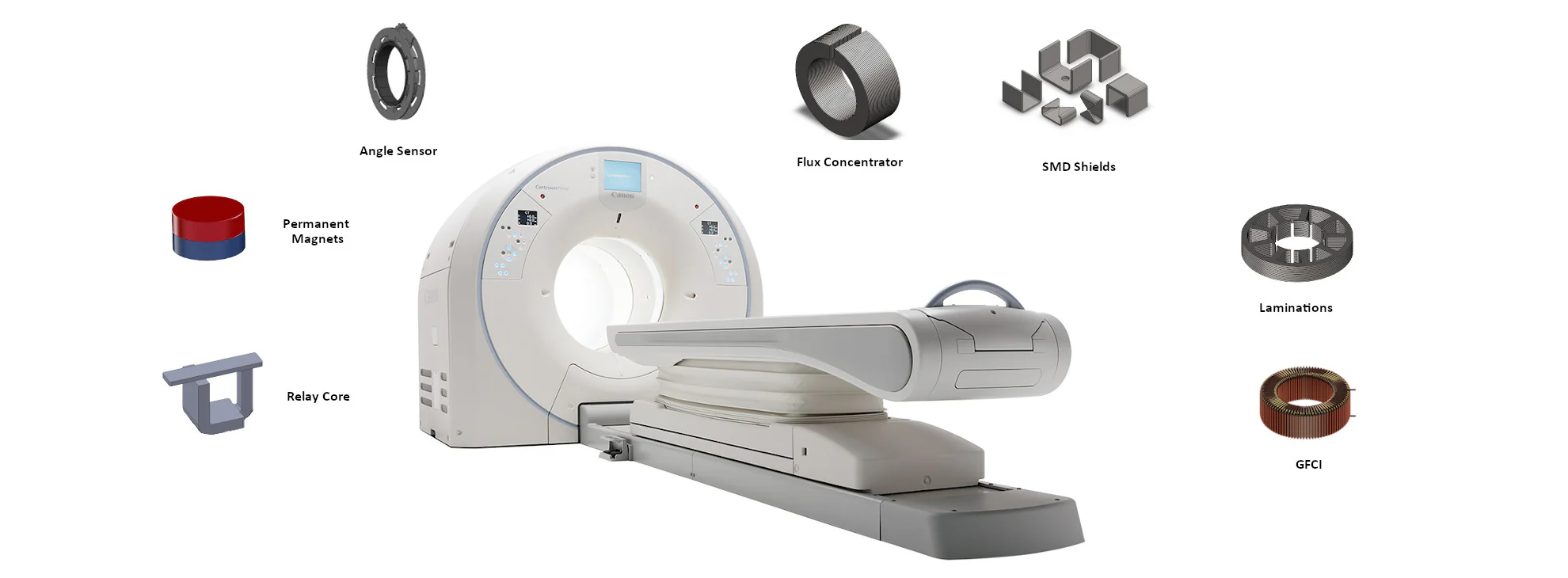

Common Applications for Titanium Components

Titanium's unique combination of high strength-to-weight ratio, biocompatibility, and excellent corrosion resistance makes it the material of choice for a wide range of demanding applications across multiple industries.

Aerospace Components

- Structural airframe components

- Engine parts and compressor blades

- Landing gear components

- Fasteners and mounting brackets

Medical Implants & Devices

- Orthopedic implants and joint replacements

- Dental implants and prosthetics

- Surgical instruments and tools

- Medical device components

Automotive Components

- Performance valves and connecting rods

- Exhaust systems and components

- Suspension components

- Racing and high-performance parts

Marine Applications

- Propeller shafts and components

- Heat exchangers and valve systems

- Desalination equipment

- Subsea components and housings

Industries Served

Aerospace

Medical

Automotive

Chemical Processing

Marine

Energy

Ready to Start Your Sheet Metal Project?

Contact us now for a free quote and professional advice