CNC Machining in Tool Steel

High hardness and stiffness, abrasion resistant. Tool steels are metal alloys with exceptionally high hardness, stiffness and abrasion resistance. Suitable for manufacturing industrial tools, dies, and precision components requiring extreme durability.

Order CNC Machined Tool Steel Parts

Custom Tool Steel Parts

Tool steels are specialized high-carbon, high-alloy steels designed to withstand extreme conditions of heat, pressure, and abrasion. These premium materials offer exceptional hardness, wear resistance, and dimensional stability, making them the ideal choice for cutting tools, dies, molds, and other high-stress industrial applications.

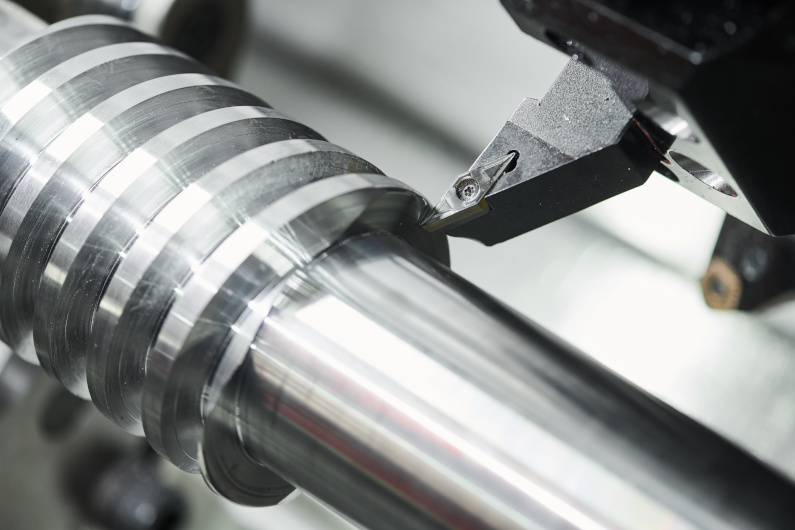

BZ Metal Products delivers precision CNC machined tool steel components with excellent mechanical properties, accuracy, and repeatability. Our advanced CNC machining capabilities include both 3-axis and 5-axis milling operations, allowing us to produce complex geometries with tight tolerances while maintaining the superior properties that make tool steels essential for demanding applications.

Exceptional Hardness

Tool steels achieve hardness values up to 68 HRC, allowing components to withstand extreme wear and maintain cutting edges longer

Heat Resistance

Specialized grades maintain hardness and structural integrity at elevated temperatures, ideal for high-temperature applications

Dimensional Stability

Minimal distortion during heat treatment ensures precise dimensions are maintained throughout the manufacturing process

CNC Machining Tool Steel Materials

BZ Metal Products offers premium tool steel grades for CNC machining. Our tool steel materials provide exceptional hardness, wear resistance, and dimensional stability for your most demanding industrial applications.

Tool Steel D2

1.2379 | X153CrMoV12-1 - Annealed state

Tool Steel D2 is a wear-resistant alloy that retains its hardness to a temperature of 425°C. It has high chromium content (12%) providing excellent wear resistance and deep hardenability, making it ideal for cutting tools and dies requiring high wear resistance.

Tool Steel A2

1.2363 | X100CrMoV5-1 - Annealed state

Tool Steel A2 is an air-hardened general purpose tool steel with good toughness and excellent dimensional stability. It offers a balanced combination of wear resistance and toughness, making it ideal for complex dies, gauges, and tooling applications.

Additional Tool Steel Grades Available by Request

Tool Steel O1

Oil-hardened steel with high hardness of 65 HRC for cutting tools

Tool Steel H13

Hot work steel with excellent toughness and heat resistance

Tool Steel S7

Shock-resistant steel with high impact toughness properties

Tool Steel M2

High-speed steel with superior wear resistance and hardness

Tool Steel Properties Overview

| Property | Tool Steel D2 | Tool Steel A2 | Units |

|---|---|---|---|

| Hardness (Annealed) | 210-255 | 190-240 | HB |

| Hardness (Hardened) | 58-62 | 57-62 | HRC |

| Tensile Strength (Annealed) | 750 | 720 | MPa |

| Yield Strength (Annealed) | 480 | 450 | MPa |

| Elastic Modulus | 210 | 210 | GPa |

| Compressive Strength | 2200 | 2000 | MPa |

| Property | Tool Steel D2 | Tool Steel A2 | Units |

|---|---|---|---|

| Density | 7.7 | 7.86 | g/cm³ |

| Melting Point | 1425 | 1430 | °C |

| Thermal Conductivity | 20-24 | 24-28 | W/m·K |

| Electrical Resistivity | 0.65 | 0.60 | Ω·mm²/m |

| Coefficient of Thermal Expansion | 10.4 | 11.5 | μm/m·K |

| Specific Heat Capacity | 460 | 460 | J/kg·K |

| Element | Tool Steel D2 | Tool Steel A2 |

|---|---|---|

| Carbon (C) | 1.40-1.60% | 0.95-1.05% |

| Chromium (Cr) | 11.00-13.00% | 4.75-5.50% |

| Molybdenum (Mo) | 0.70-1.20% | 0.90-1.40% |

| Vanadium (V) | 0.50-1.10% | 0.15-0.50% |

| Manganese (Mn) | 0.30-0.60% | 0.40-1.00% |

| Silicon (Si) | 0.10-0.60% | 0.10-0.50% |

Tool Steel Characteristics & Applications

Exceptional Wear Resistance

Tool steels are formulated to resist wear, abrasion, and deformation even under extreme conditions. The high carbon content combined with chromium, molybdenum, and vanadium creates carbides that significantly enhance wear resistance.

Heat Treatment Response

Different tool steel grades respond to heat treatment in various ways. A-series steels are air-hardening, D-series have high chromium for deep hardening, O-series are oil-hardening, and H-series maintain hardness at elevated temperatures.

Machinability Considerations

Tool steels are typically machined in the annealed condition (25-30 HRC) to facilitate processing. Special tooling and optimized cutting parameters are required to machine these materials efficiently while minimizing tool wear.

Fatigue & Impact Resistance

Tool steels offer varying degrees of toughness and impact resistance based on their composition. For applications requiring high impact resistance, shock-resistant grades like S7 provide superior performance without sacrificing hardness.

Tool Steel CNC Machining Services

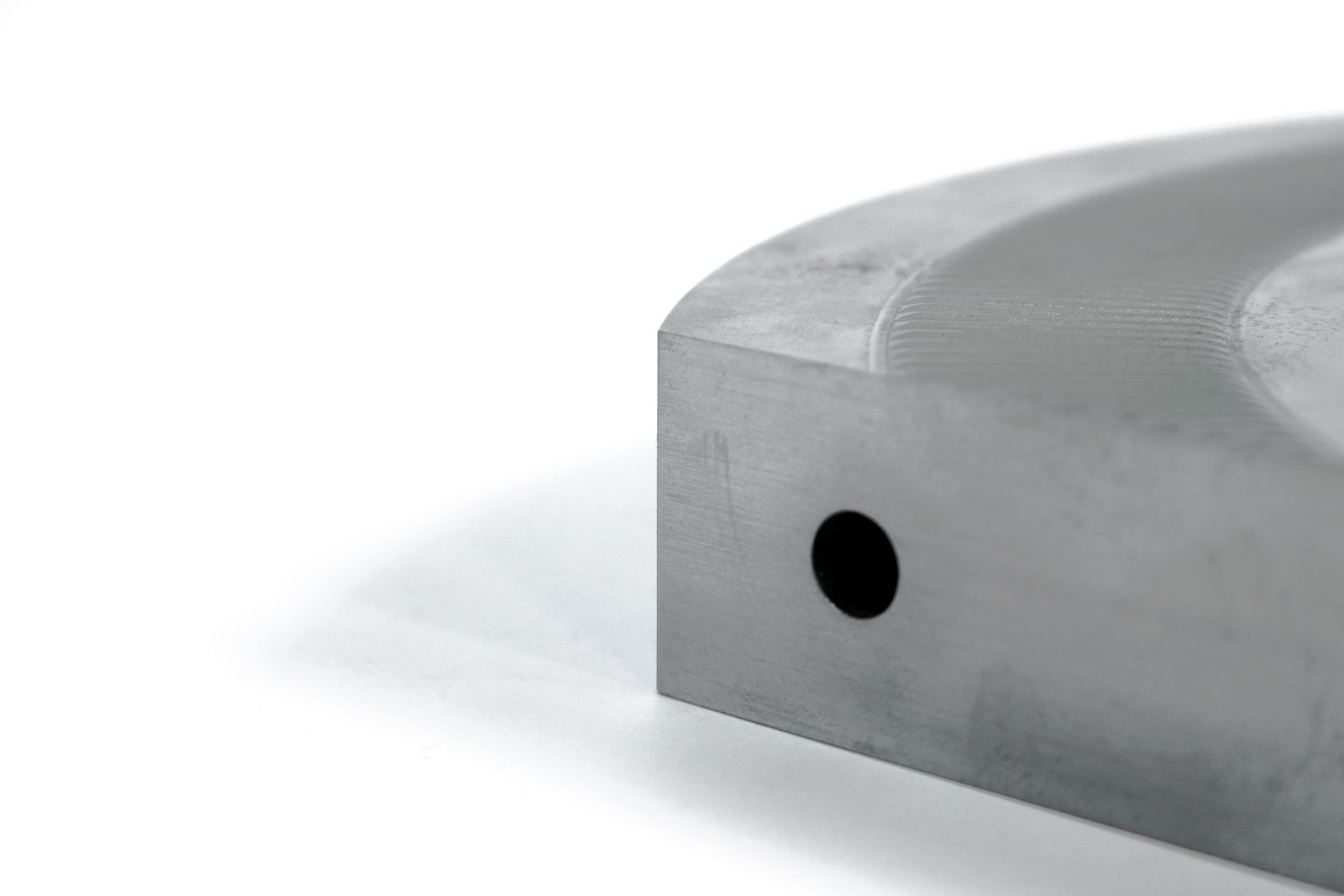

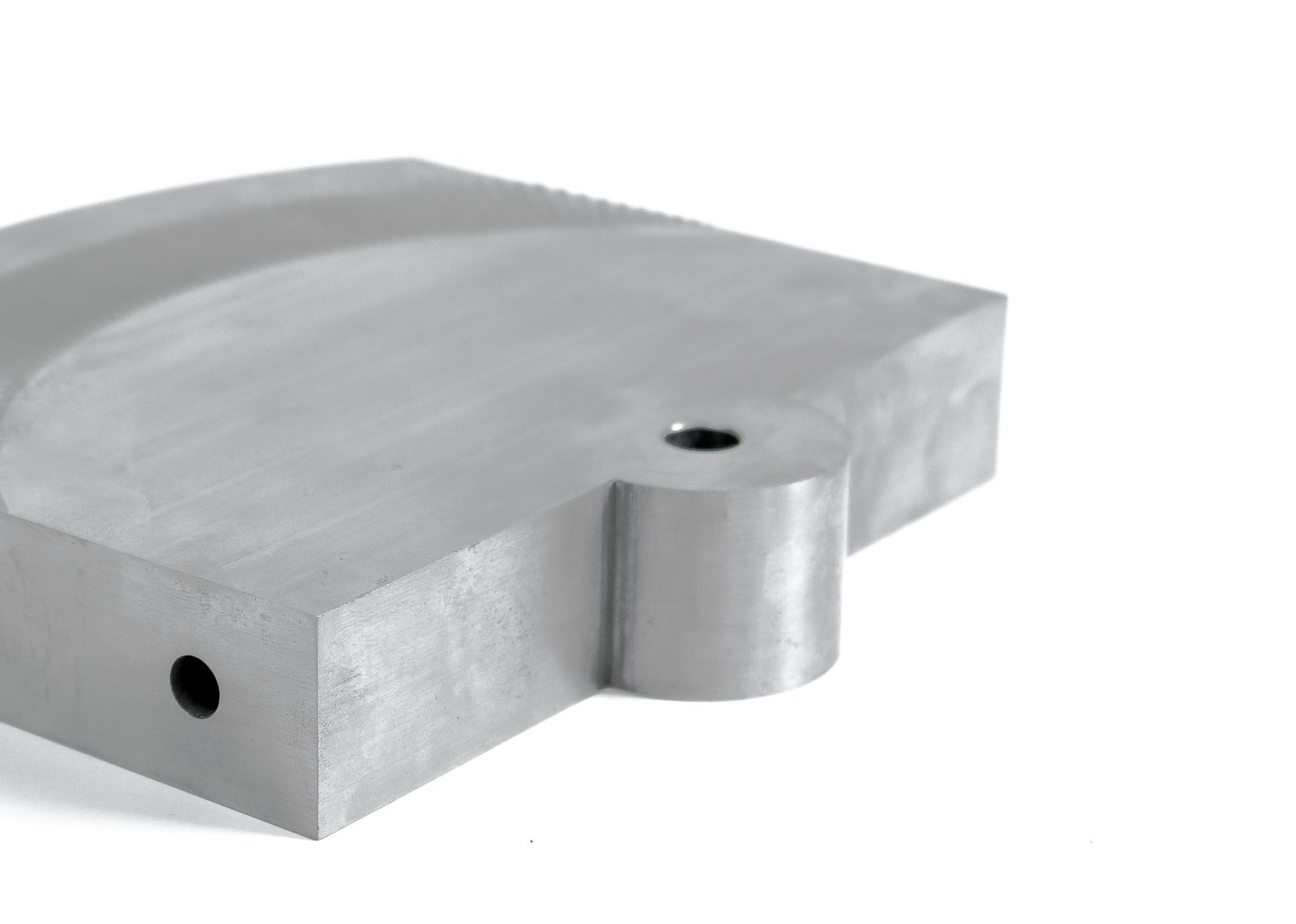

BZ Metal Products specializes in precision CNC machining of tool steel components, from simple prototypes to complex production parts. Our expertise in working with these challenging materials allows us to deliver high-quality, dimensionally accurate components for even the most demanding industrial applications.

Expert Tool Steel Machining

Our specialized tooling and machining techniques are optimized for hardened tool steels. We maintain tight tolerances while minimizing tool wear and ensuring consistent surface quality. Our machinists have extensive experience with the unique challenges of tool steel processing.

High Precision Components

We deliver tool steel components with tolerances as tight as ±0.025mm using advanced CNC milling equipment. Our quality control process ensures dimensional accuracy even for complex geometries. Every part is inspected using precision measurement equipment.

Heat Treatment Services

We offer comprehensive heat treatment options including annealing, hardening, tempering, and stress relieving to achieve your specified mechanical properties. Our process controls ensure minimal distortion and predictable results for your tool steel components.

Tool Steel Machining Process

Our tool steel CNC machining process is carefully optimized to achieve exceptional quality while managing the unique challenges of these high-hardness materials. We follow a systematic approach that ensures consistent results and minimizes lead times.

Material Selection & Preparation

We select the appropriate tool steel grade based on your application requirements and mechanical property needs. Material is sourced in the annealed condition to facilitate initial machining operations.

Design Review & Engineering

Our engineering team reviews your design for manufacturability, suggesting modifications if needed to optimize for tool steel properties and machining constraints while maintaining functionality.

CNC Programming & Toolpath Optimization

We develop optimized CNC programs with tool paths specifically designed for tool steel machining, incorporating appropriate cutting speeds, feeds, and tool selection to maximize efficiency and quality.

Pre-Machining Heat Treatment (Optional)

For some applications, we perform stress relief or annealing before machining to ensure dimensional stability throughout the manufacturing process.

Precision CNC Machining

Components are machined using specialized cutting tools and optimized parameters for tool steels. We perform roughing and finishing operations to achieve near-net shape with appropriate machining allowances for any subsequent heat treatment.

Post-Machining Heat Treatment

Parts undergo hardening and tempering processes to achieve the specified hardness and mechanical properties. Our heat treatment protocols ensure minimal distortion while maximizing material performance.

Final Finishing & Surface Treatment

After heat treatment, we perform final grinding, honing, or lapping operations to achieve precise dimensions and surface finish requirements. Surface treatments such as black oxide or polishing can be applied as needed.

Quality Inspection & Certification

All components undergo rigorous dimensional inspection and hardness testing to verify conformance to specifications. We provide quality documentation and material certifications with every order.

CNC Machining Specifications

Price

$$$

Lead Time

< 15 days

Wall Thickness

0.8 mm

Tolerances

±0.125 mm

Max Part Size

150 x 80 x 80 cm

Surface Finish

Ra 0.8 - 3.2 μm

Common Applications for Tool Steel Components

Tool steel components produced through CNC machining are used across a wide range of industries where exceptional hardness, wear resistance, and dimensional stability are crucial for performance and longevity.

Cutting Tools & Dies

- Stamping dies and punches

- Cutting blades and shears

- Forming dies and tools

- Custom cutting implements

Industrial Tooling

- Industrial molds

- Extrusion dies

- Forging dies

- Thread rolling dies

Wear Components

- Guide bushings and sleeves

- Wear plates and liners

- Gears and sprockets

- Rollers and shafts

Precision Measuring Equipment

- Gauges and dimensional references

- Inspection fixtures

- Calibration tools

- Measuring instruments

Industries Served

Automotive

Aerospace

Manufacturing

Oil & Gas

Defense

Medical

Frequently Asked Questions

Get answers to common questions about tool steel CNC machining and the properties that make these materials ideal for high-wear applications. If you have additional questions, please contact our engineering team.

What are the advantages of using tool steel for CNC machined components?

Tool steels offer several significant advantages for CNC machined components:

- Exceptional Hardness: Tool steels can achieve hardness values of 58-68 HRC after heat treatment, providing superior wear resistance and edge retention for cutting tools and dies.

- Dimensional Stability: Properly heat-treated tool steels maintain their dimensions with minimal distortion, making them ideal for precision components.

- High Compressive Strength: Tool steels can withstand extreme compressive forces without deformation, essential for tooling applications.

- Heat Resistance: Many tool steel grades maintain their hardness and mechanical properties at elevated temperatures, allowing them to perform in high-temperature applications.

- Wear Resistance: The carbide structures in tool steels provide exceptional resistance to abrasive wear, extending component life in harsh operating conditions.

- Impact Resistance: Certain tool steel grades offer excellent toughness combined with high hardness, making them suitable for shock-loading applications.

- Specialized Formulations: Different tool steel families (A, D, H, O, etc.) are optimized for specific applications, allowing for tailored material selection.

These properties make tool steels the preferred material for cutting tools, dies, molds, and other high-wear components that require extreme durability and dimensional stability.

How do I choose the right tool steel grade for my application?

Selecting the appropriate tool steel grade depends on several application-specific factors:

- Operating Temperature: If your component will operate at elevated temperatures, consider hot-work tool steels (H-series) that maintain hardness up to 500°C or higher.

- Wear Resistance Requirements: For extreme abrasion resistance, high-carbon, high-chromium tool steels (D-series) provide excellent wear characteristics.

- Toughness Needs: Applications with impact or shock loading require shock-resistant tool steels (S-series) that offer a balance of hardness and toughness.

- Size and Geometry: For large components or complex shapes, consider air-hardening steels (A-series) that minimize distortion during heat treatment.

- Corrosion Considerations: If corrosion resistance is needed, stainless tool steels containing higher chromium levels are recommended.

- Machinability: For complex geometries requiring extensive machining, oil-hardening tool steels (O-series) offer better machinability in the annealed condition.

- Cost Constraints: Water-hardening and oil-hardening tool steels are generally more economical than premium grades like high-speed or powder metallurgy steels.

Our engineering team can help you evaluate these factors to select the optimal tool steel grade for your specific application. We consider operating conditions, mechanical requirements, and production factors to recommend the most appropriate material.

What tolerances can be achieved with tool steel CNC machining?

Tool steel CNC machining can achieve excellent tolerances, though the specific capabilities depend on several factors:

- Standard Tolerances: For most tool steel components, we maintain tolerances of ±0.125 mm (±0.005") as a standard.

- Precision Tolerances: For critical features, we can achieve tolerances as tight as ±0.025 mm (±0.001") using specialized tooling and machining strategies.

- Heat Treatment Considerations: When components require heat treatment after machining, we account for potential dimensional changes by incorporating appropriate machining allowances.

- Post-Heat Treatment Finishing: For the tightest tolerances on hardened components, we can perform grinding, honing, or EDM operations after heat treatment to achieve tolerances of ±0.005 mm (±0.0002") on specific features.

- Surface Finish: Our CNC machining processes can achieve surface finishes of Ra 0.8-3.2 μm on tool steel components before any post-processing.

It's important to note that achieving extremely tight tolerances on tool steel components typically requires a combination of precise machining in the annealed state, carefully controlled heat treatment, and post-treatment finishing operations. Our engineering team can develop a manufacturing plan that ensures your tolerance requirements are met while managing costs effectively.

What surface treatments are available for tool steel components?

We offer several surface treatment options for tool steel components to enhance performance and appearance:

- Black Oxide: A conversion coating that provides mild corrosion resistance and a uniform black appearance without dimensional changes.

- Nitriding: A surface hardening process that diffuses nitrogen into the surface, creating an extremely hard layer (up to 70 HRC) with excellent wear resistance.

- PVD Coatings: Thin-film coatings like TiN, TiCN, or TiAlN that significantly enhance surface hardness, wear resistance, and friction characteristics.

- CVD Coatings: Hard coatings applied at higher temperatures than PVD, providing excellent adhesion and uniform coverage for complex geometries.

- Chrome Plating: Provides a hard, corrosion-resistant surface with low friction characteristics, suitable for both functional and decorative applications.

- Polishing: Mechanical polishing to achieve mirror-like finishes (Ra 0.1 μm or better) for mold applications or aesthetic requirements.

- EDM Surface Texturing: Creates controlled textures or patterns on the surface for functional or aesthetic purposes.

The optimal surface treatment depends on your application requirements, including wear resistance needs, operating environment, and aesthetic considerations. Our team can recommend the most appropriate treatment based on your specific performance criteria.

What design considerations are important for tool steel CNC machining?

When designing parts for tool steel CNC machining, consider these important factors:

- Wall Thickness: Maintain minimum wall thickness of 0.8mm to ensure structural integrity and prevent distortion during machining and heat treatment.

- Internal Corners: Design with internal corner radii of at least 1/3 the depth of the pocket to reduce stress concentrations and tool wear.

- Feature Transitions: Incorporate gradual transitions between sections of different thicknesses to minimize stress concentrations and potential crack formation.

- Heat Treatment Allowance: Include dimensional allowances (typically 0.1-0.3mm) for finishing operations after heat treatment when tight tolerances are required.

- Uniform Cross-Sections: Design components with relatively uniform cross-sections when possible to minimize distortion during heat treatment.

- Deep Cavity Designs: For deep cavities or pockets, consider segmented construction or EDM processing alternatives to avoid excessive tool projection.

- Thread Design: Use rolled threads rather than cut threads where possible, and specify thread relief for internal threads to ensure full thread engagement.

- Stress Relief Considerations: Incorporate stress relief features like slots or gaps in massive sections to manage thermal expansion and contraction.

Our engineering team can provide design for manufacturability (DFM) reviews of your parts to ensure optimal manufacturability, performance, and cost-effectiveness. Early involvement of our manufacturing engineers can help identify potential issues and optimize your design for tool steel manufacturing.

Get Your Tool Steel Parts Into Production

Ready to leverage the exceptional durability and performance of tool steel for your components? BZ Metal Products offers expert CNC machining services for all tool steel grades. From prototypes to production runs, we ensure high-quality parts that meet your exact specifications.